Preparation of fuel blends

A technology for blends and fuels, applied in the field of preparing renewable fuel blends, can solve problems such as difficulty in improving cloud point, and achieve the effects of lowering storage temperature and improving the clogging point of cold filters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0069] Table 2 shows the properties of TOP, AF and UCO based fuels or fuel components determined using various test methods.

[0070] Table 2. Properties of TOP, AF and UCO based fuels

[0071]

Embodiment 3

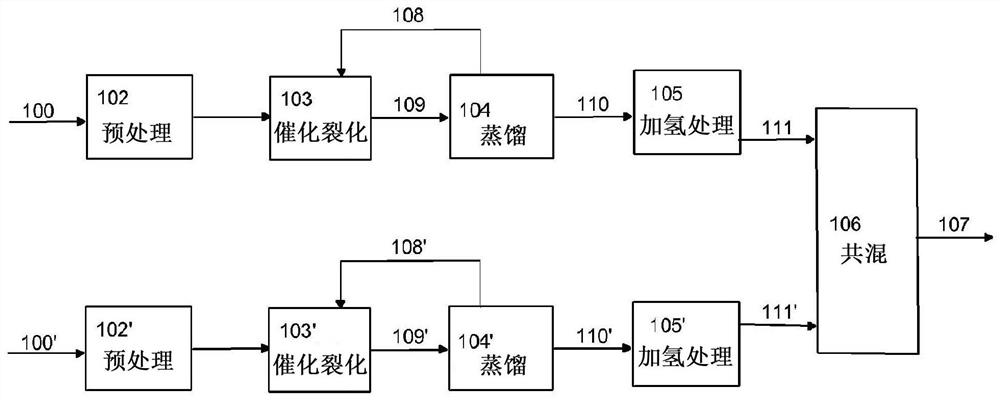

[0073] according to Figure 1a Fuel blends were prepared using the protocol shown in . The tall oil pitch (TOP) feed used in the experiment was analyzed, which contained the properties shown in Table 3, the animal fat (AF) feed used in the experiment was analyzed, which contained the properties shown in Table 4, and the The waste cooking oil (UCO) feed used in the experiments contained the properties shown in Table 5. The TCC reactor was operated at 460°C at atmospheric pressure with a WHSV setting of 0.3 l / h. The reactor was filled with TCC catalyst (silicon aluminum oxide, 3-5 mm) using glass beads at the top of the catalyst bed and quartz sand at the bottom. The obtained product was distilled using a batch still and a thin film distillation unit to obtain a diesel (160-370° C.) fraction and hydrotreated.

[0074] Table 3. TOP analysis results

[0075]

[0076]

[0077]

[0078] Table 4. AF analysis results

[0079]

[0080] Table 5. UCO analysis results

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com