Gas density relay with sealing performance self-checking function and implementation method thereof

A technology of gas density and sealing performance, applied in the field of electric power, which can solve the problems of flashover, damage, and reduction of insulation strength on the surface of insulating parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

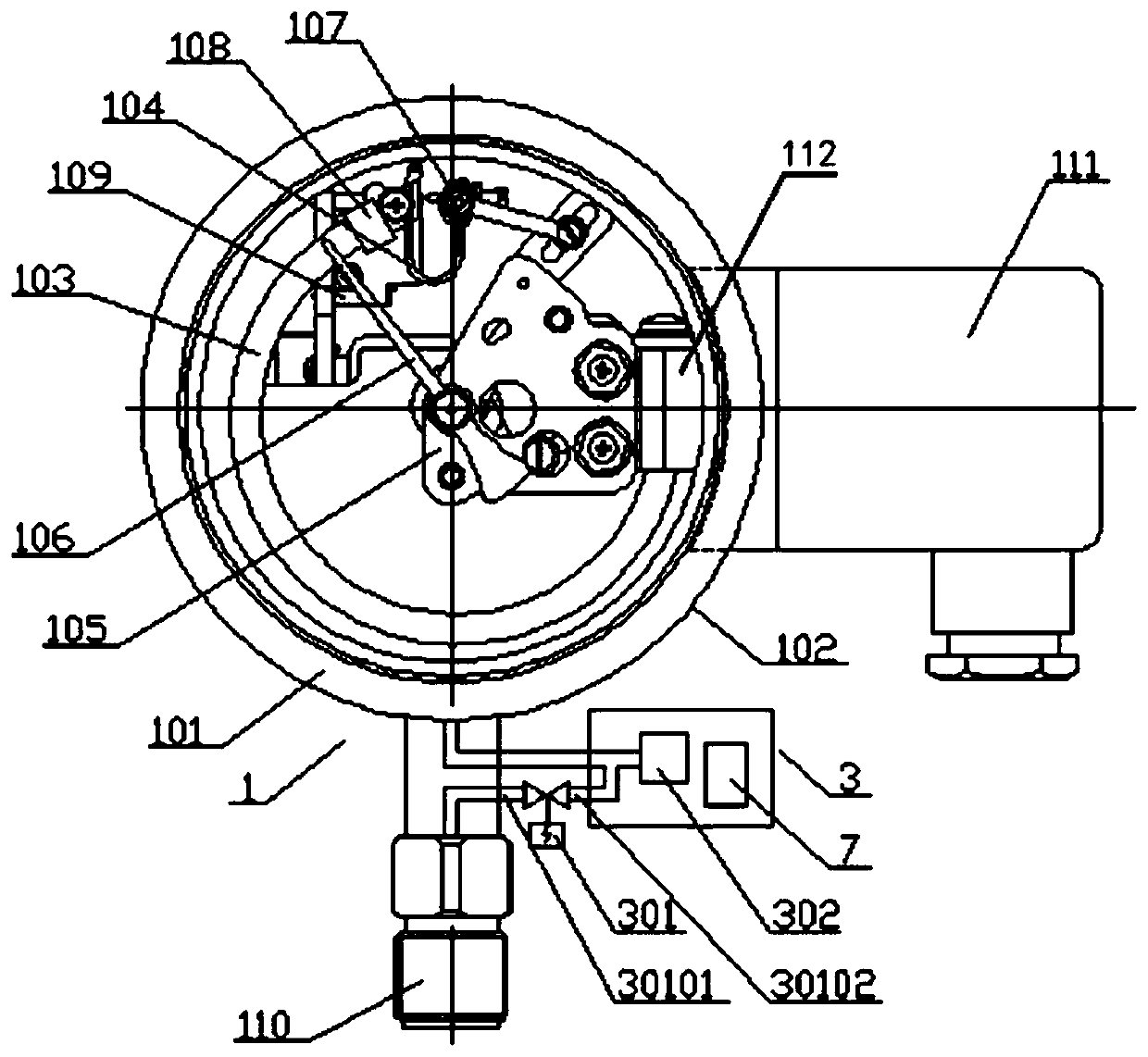

[0083] figure 1 It is a schematic structural diagram of a gas density relay with sealing performance self-test for high and medium voltage electrical equipment according to Embodiment 1 of the present invention. Such as figure 1 As shown, a gas density relay or a gas density monitoring device with sealing performance self-test mainly includes: a gas density relay body 1 , a gas leakage performance diagnostic detector 3 and an intelligent control unit 7 . The gas leakage performance diagnosis detector 3 described in this embodiment is arranged outside the gas density relay body 1 and includes an electric control valve 301 and a pressure sensor 302 . The implementation process of this example is that one end of the electric control valve 301 is provided with an air inlet port 30101 connected to the electrical equipment, and the air inlet interface 30101 is connected with the electrical equipment through the equipment connection joint 110, and the other end of the electric contr...

Embodiment 2

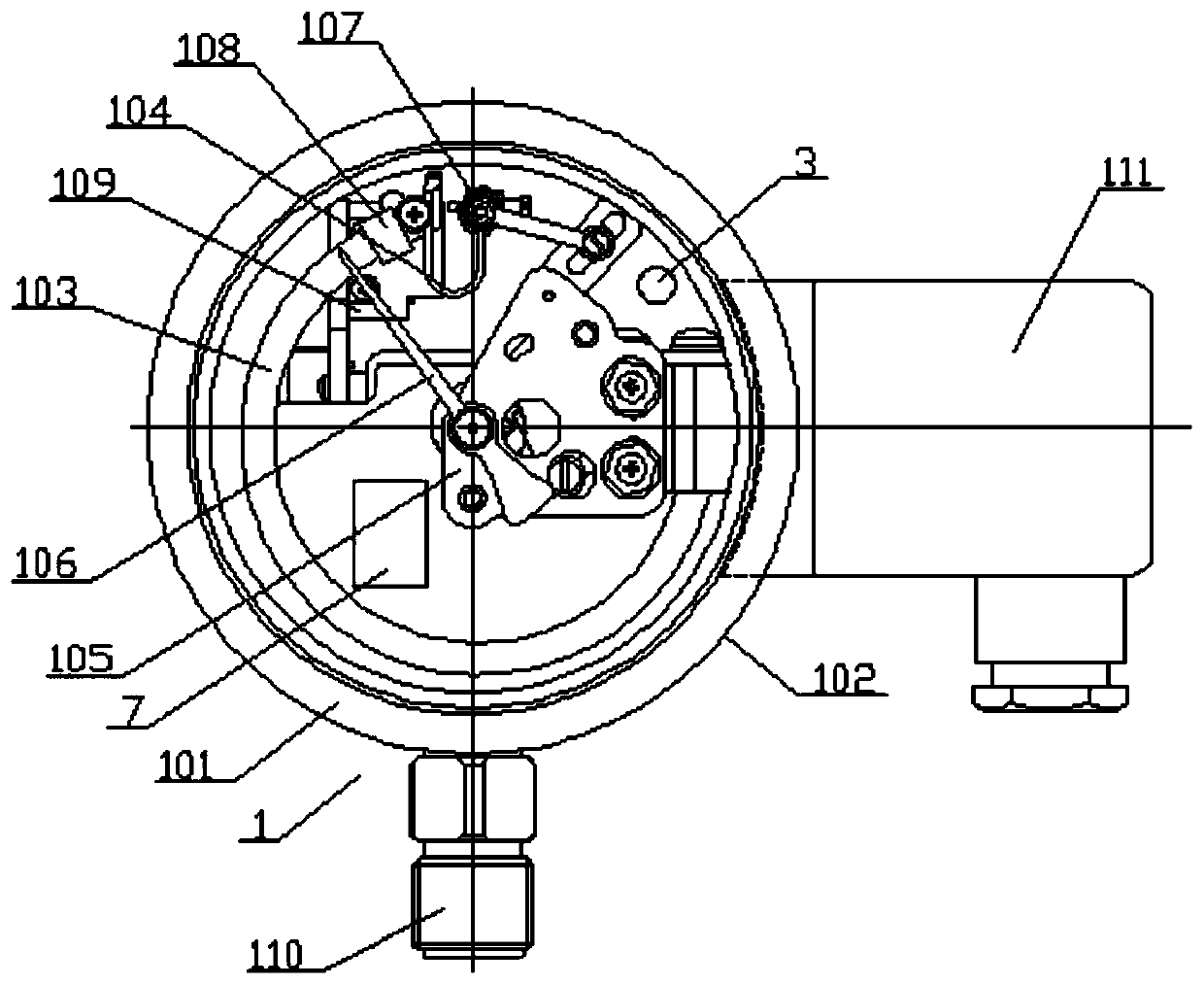

[0088] figure 2 It is a schematic diagram of the front structure of a gas density relay with sealing performance self-test for high-voltage electrical equipment in Embodiment 2 of the present invention. Such as figure 2 As shown, the difference from Embodiment 1 is that the gas leakage performance diagnostic detector 3 in this embodiment is a pressure sensor, and the pressure sensor 3 is arranged in the housing 102 of the gas density relay body 1 and connected to the intelligent control unit 7 . The pressure sensor 3 uploads the collected pressure signal P in the casing 102 of the gas density relay body 1 to the intelligent control unit 7 . If the pressure signal P in the housing 102 of the gas density relay body 1 壳 Gradually become larger, the intelligent control unit 7 or the backstage send an air leakage alarm signal or / and information; or, the pressure signal P in the housing 102 of the gas density relay body 1 壳 The ascent speed PS 壳Z Higher than the set raising s...

Embodiment 3

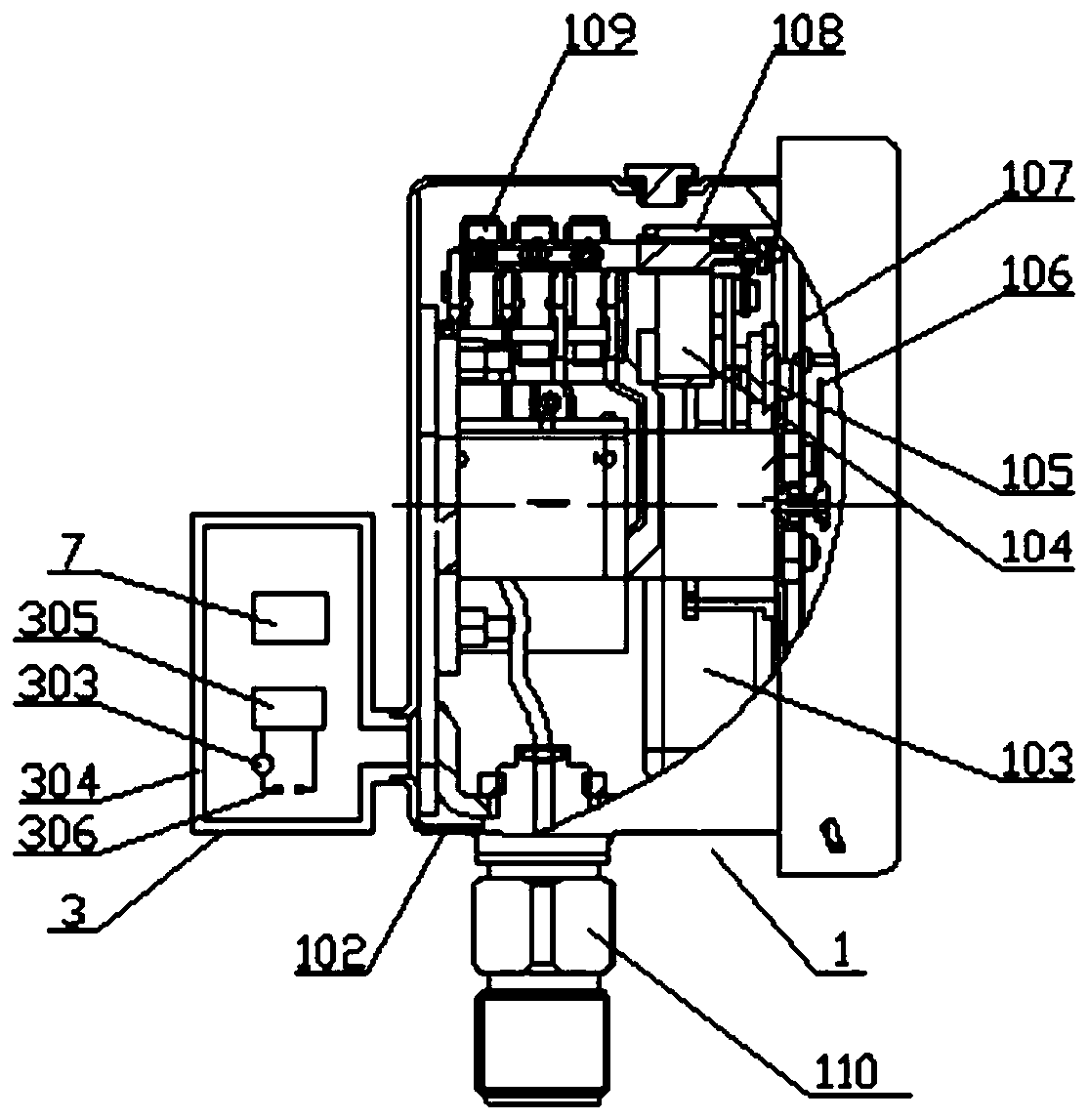

[0091] image 3 It is a structural schematic diagram of a gas density relay or a gas density monitoring device with sealing performance self-test for high-voltage electrical equipment in Embodiment 3 of the present invention. Such as image 3 As shown, the gas density relay or gas density monitoring device with sealing performance self-test according to the third embodiment of the present invention mainly includes: a gas density relay body 1 , a sealing performance detector 3 and an intelligent control unit 7 . The sealing performance detector 3 includes a voltage actuator 305, an electrode 306, and a current detector 303, and the voltage actuator 305, the electrode 306, and the current detector 303 can be arranged in the housing 102 of the gas density relay body 1; or , the sealing performance detector 3 may also include a gas cover 304, the gas cover 304 is arranged outside the gas density relay body 1, and communicates with the housing 102 of the gas density relay body 1 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com