Strong heat dissipation structure capable of being used for heat dissipation of optoelectronic device and preparation method of structure

A technology for optoelectronic devices and heat dissipation structures, which is applied in the fields of electro-solid devices, semiconductor/solid-state device manufacturing, and electrical components. , Improve heat dissipation efficiency and effectively conduct heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

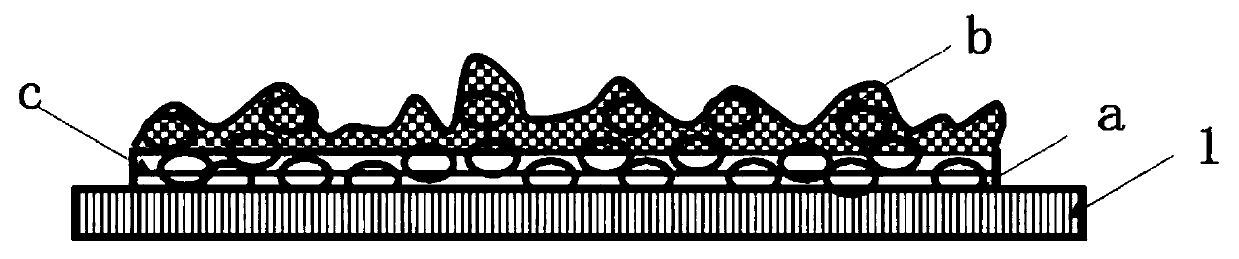

[0030] like figure 1 As shown, this embodiment provides a strong heat dissipation structure that can be used for heat dissipation of optoelectronic devices, including a bottom-up base 1 and a strong heat dissipation film. The total thickness of the strong heat dissipation film is 15 μm, and the raw materials of the strong heat dissipation film are as follows: The weight ratio includes the following components: 50% heat absorbing agent, 10% intermediate connecting agent, 35% cooling agent, and 5% protecting agent;

[0031] The heat-absorbing agent is silver nanospheres, the intermediate connecting agent is a single-layer two-dimensional MoS2 film, the cooling agent is silver nanowires, and the protective agent is a mixture of Schima trunk and leaf extract containing 5% polyether-modified polysiloxane.

[0032] The preparation method is as follows:

[0033] Step 1. First, clean the radiator or the substrate 1 on the surface to be sprayed, and perform ultrasonic cleaning with de...

Embodiment 2

[0042] like figure 1 As shown, this embodiment provides a strong heat dissipation structure that can be used for heat dissipation of optoelectronic devices, including a bottom-up base 1 and a strong heat dissipation film. The total thickness of the strong heat dissipation film is 15 μm, and the raw materials of the strong heat dissipation film are as follows: The weight ratio includes the following components: 45% heat absorbing agent, 15% intermediate connecting agent, 35% cooling agent, and 5% protecting agent;

[0043] The heat-absorbing agent is silver nanospheres, the intermediate connecting agent is a single-layer two-dimensional MoS2 film, the cooling agent is silver nanowires, and the protective agent is a mixture of Schima trunk and leaf extract containing 5% polyether-modified polysiloxane.

[0044] The preparation method is as follows:

[0045] Step 1. First, clean the radiator or the substrate 1 on the surface to be sprayed, and perform ultrasonic cleaning with de...

Embodiment 3

[0054] like figure 1 As shown, this embodiment provides a strong heat dissipation structure that can be used for heat dissipation of optoelectronic devices, including a bottom-up base 1 and a strong heat dissipation film. The total thickness of the strong heat dissipation film is 15 μm, and the raw materials of the strong heat dissipation film are as follows: The weight ratio includes the following components: 45% heat absorbing agent, 20% intermediate connecting agent, 30% cooling agent, and 5% protecting agent;

[0055] The heat-absorbing agent is silver nanospheres, the intermediate connecting agent is a single-layer two-dimensional MoS2 film, the cooling agent is silver nanowires, and the protective agent is a mixture of Schima trunk and leaf extract containing 5% polyether-modified polysiloxane.

[0056] The preparation method is as follows:

[0057] Step 1. First, clean the radiator or the substrate 1 on the surface to be sprayed, and perform ultrasonic cleaning with de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com