Processing method of sweet and mellow black tea

A processing method and technology for black tea, applied in the processing of sweet and mellow black tea and in the field of tea processing, can solve the problems affecting the economic benefit of the black tea industry, unstable quality of black tea products, and low level of standardized processing, so as to promote mass production, facilitate the taste and Aroma, enhance the effect of high-volume production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

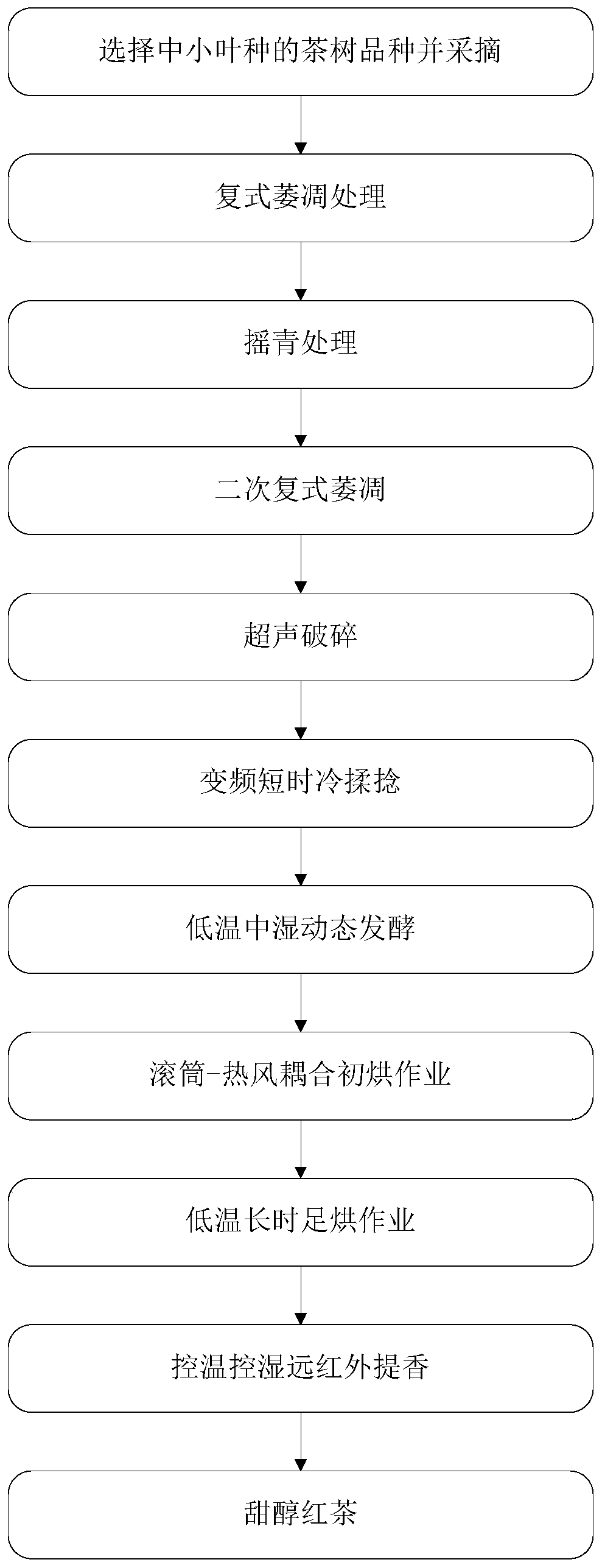

[0048] Such as figure 1 所示,一种甜醇红茶的加工方法,包括:

[0049] (1)选用适制红茶的中小叶种的茶树品种的鲜叶作为原料,其中:

[0050] 适制红茶的中小叶种的茶树品种为福鼎大白;

[0051] (2)3月下旬(3月28日),采摘上述中小叶种的茶树品种的鲜叶,其中:

[0052] 鲜叶的嫩度为1芽1叶~1芽2叶初展;

[0053] 所述鲜叶的氨基酸含量在3.0wt%,茶多酚含量25wt%;

[0054] (3)将步骤(2)采摘的鲜叶置于连续化萎凋系统进行萎凋处理,将其萎凋至叶含水率68%,其中:

[0055] 环境温度控制在26℃,相对湿度控制在65%,摊叶厚度4cm,采用热风红光萎凋和冷风白光萎凋的复式萎凋组合交替进行,充分促进了叶内可溶性糖和氨基酸含量的增加。复式萎凋组合的具体条件为:30℃的热风温度、10000m3 / h的通风风量,搭配光强6000lux的红光萎凋2.0h,然后以22℃的冷风温度、5000m3 / h的通风风量,搭配光强3000lux的白光萎凋1.0h,交替进行2次。

[0056] (4)将经过步骤(3)处理后的萎凋叶用传输带传送至连续化摇青机进行摇青处理,促进了甜花香类香气物质的生产,加速叶内酶促反应。 摇青的具体条件为:环境温度控制在24℃,相对湿度控制在70%,摇青1.5min,摇青叶在传输带上摊凉回水3min,后再进行摇青和摊凉交替进行4 Second-rate.

[0057] (5)将经过步骤(4)处理的摇青叶用传输带传送至连续化萎凋系统或人工气候室进行二次萎凋,将其萎凋至叶含水率60%,其中:

[0058] 二次萎凋的环境温度控制在26℃,相对湿度控制在60%,采用热风红光萎凋和冷风白光萎凋的复式萎凋组合交替进行。具体条件为:30℃的热风温度、10000m 3 / h的热风风量,搭配光强6000lux的红光萎凋2h,然后以22℃的冷风温度、10000m 3 / h的热风风量,搭配光强3000lux的白光萎凋1h,交替进行2次。

[0059] (6)将经过步骤(5)处理的摇青叶用传输带传送至超声破碎设备进行超声破碎,促进叶细胞膜和液泡膜破碎,促进叶内酶类与底物生化反应的充分进行。超声处理条件为:摊叶厚度为6cm,超声破碎时间为...

Embodiment 2

[0069] 一种甜醇红茶的加工方法,包括:

[0070] (1)选用适制红茶的中小叶种的茶树品种的鲜叶作为原料,其中:

[0071] 适制红茶的中小叶种的茶树品种为鸠坑;

[0072] (2)5月上旬,采摘上述中小叶种的茶树品种的鲜叶,其中:

[0073] 鲜叶的嫩度为1芽2叶~1芽3叶初展;

[0074] 所述鲜叶的氨基酸含量在5.0wt%,茶多酚含量30wt%;

[0075] (3)将步骤(2)采摘的鲜叶置于连续化萎凋系统进行萎凋处理,将其萎凋至叶含水率72%,其中:

[0076] 环境温度控制在30℃,相对湿度控制在75%,摊叶厚度6cm,采用热风红光萎凋和冷风白光萎凋的复式萎凋组合交替进行,充分促进了叶内可溶性糖和氨基酸含量的增加。复式萎凋组合的条件为:32℃的热风温度、12000m 3 / h的通风风量,搭配光强8000lux的红光萎凋2.5h,然后以24℃的冷风温度、6000m 3 / h的通风风量,搭配光强5000lux的白光萎凋1.5h,交替进行3次。

[0077] (4)将经过步骤(3)处理后的萎凋叶用传输带传送至连续化摇青机进行摇青处理,促进了甜花香类香气物质的生产,加速叶内酶促反应。 摇青的具体条件为:环境温度控制在28℃,相对湿度控制在80%,摇青2min,摇青叶在传输带上摊凉回水5.0min,后再进行摇青和摊凉交替进行6 Second-rate.

[0078] (5)将经过步骤(4)处理的摇青叶用传输带传送至连续化萎凋系统或人工气候室进行二次萎凋,将其萎凋至叶含水率64%,其中:

[0079] 二次萎凋的环境温度控制在30℃,相对湿度控制在70%,采用热风红光萎凋和冷风白光萎凋的复式萎凋组合交替进行。复式萎凋组合的具体条件为:32℃的热风温度、12000m 3 / h的热风风量,搭配光强8000lux的红光萎凋2h,然后以24℃的冷风温度、12000m 3 / h的热风风量,搭配光强5000lux的白光萎凋1h,交替进行3次。

[0080] (6)将经过步骤(5)处理的摇青叶用传输带传送至超声破碎设备进行超声破碎,促进叶细胞膜和液泡膜破碎,促进叶内酶类与底物生化反应的充分进行。超声处理条件为:摊叶厚度为8cm,超声破碎时间为1.5min,超声破碎的频率为60KH...

Embodiment 3

[0090] A processing method for sweet and mellow black tea, comprising:

[0091] (1) select the fresh leaf of the tea tree kind of the middle and small leaf species that is suitable for black tea as raw material, wherein:

[0092] Longjing 43 is a tea tree variety suitable for making black tea with medium and small leaves;

[0093] (2) In the first ten days of April, pick the fresh leaves of the above-mentioned small and medium-leaved tea tree varieties, of which:

[0094] The tenderness of fresh leaves is from 1 bud and 1 leaf to 1 bud and 2 leaves;

[0095] The amino acid content of the fresh leaves is 4wt%, and the tea polyphenols content is 27wt%;

[0096] (3) The fresh leaves picked in step (2) are placed in a continuous withering system for withering treatment, and withered to a leaf moisture content of 70%, wherein:

[0097] The ambient temperature is controlled at 28°C, the relative humidity is controlled at 70%, and the thickness of the spread leaves is 8cm. The com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com