Electrically driven engine integrated power system

A power system and engine technology, applied in the direction of engine starting, engine motor starting, engine components, etc., can solve the problems of low system efficiency, poor coaxiality, large axial size, etc., and achieve high system reliability and universal Good performance and small axial dimension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] For ease of understanding, the technical solutions of the present invention are further specifically described below in conjunction with the accompanying drawings and through embodiments:

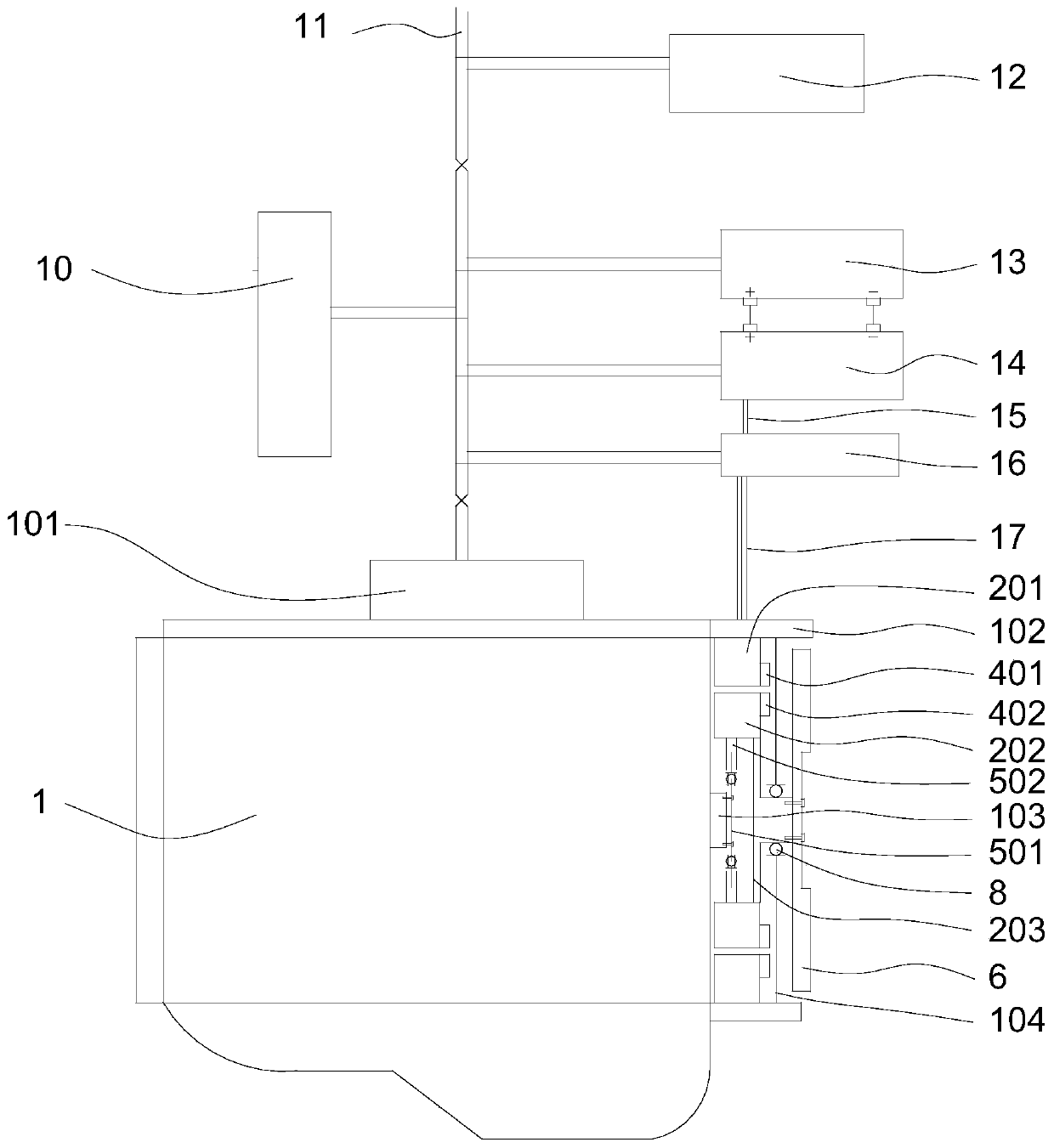

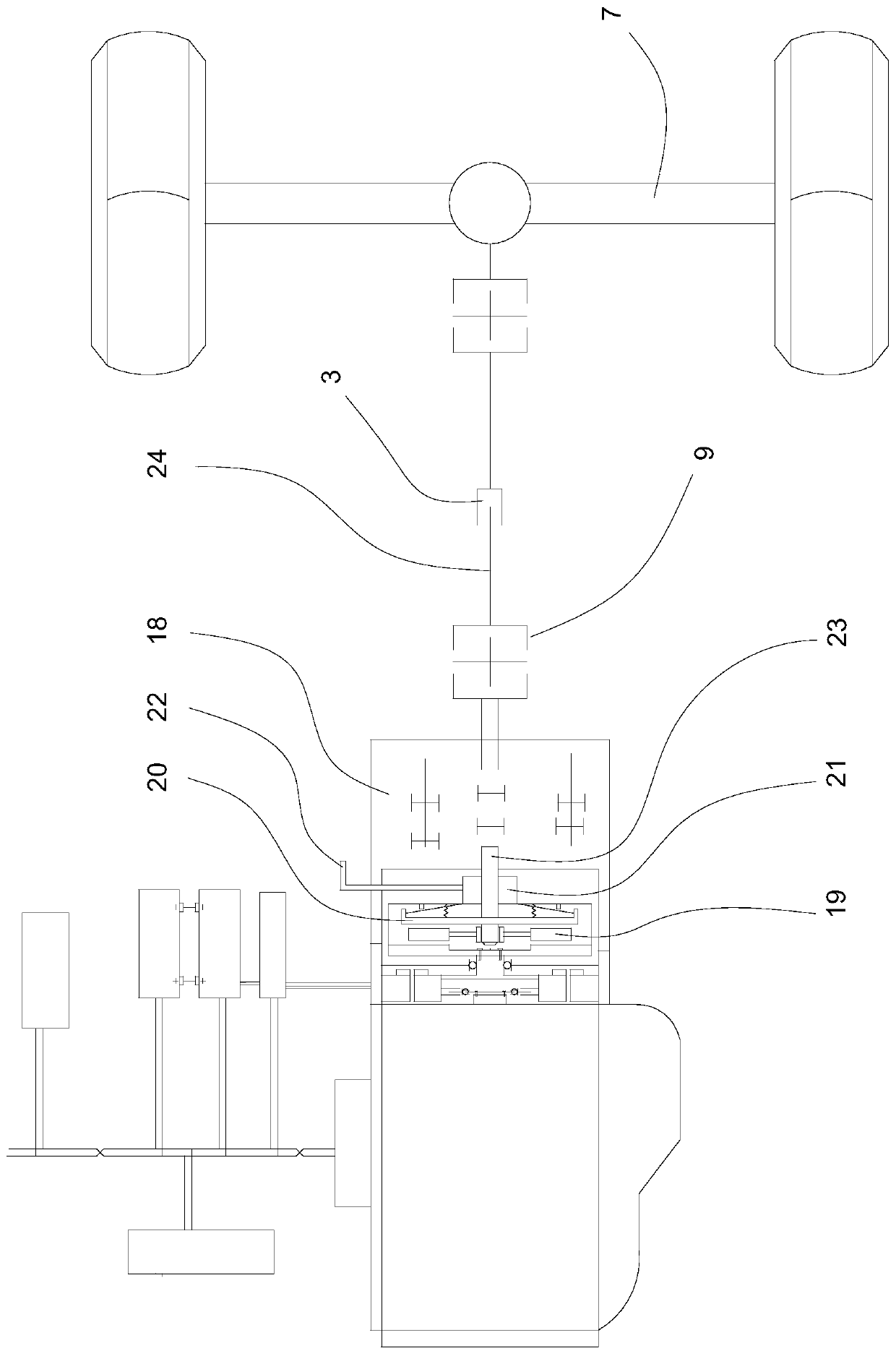

[0046] Such as figure 1 with figure 2 As shown, an electric drive engine integrated power system includes an engine body 1, an engine crankshaft output flange 103, a torsional shock absorber input 501, a torsional shock absorber output 502, a power motor stator 201, and a power motor rotor 202 , Rotary encoder stator 402, Rotary encoder rotor 401, Flywheel housing 102, Power motor output terminal 203, Flywheel 6, Power motor casing 104, Support bearing 8, Power control unit 10, Engine control unit 101, Communication harness 11, Instrument 12. Power battery 13, power distribution unit 14, power motor inverter 16, power DC bus 15, power three-phase line 17, gearbox 18, clutch friction plate 19, clutch pressure plate 20, release bearing 21, release dial Fork 22, gearbox input shaft 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com