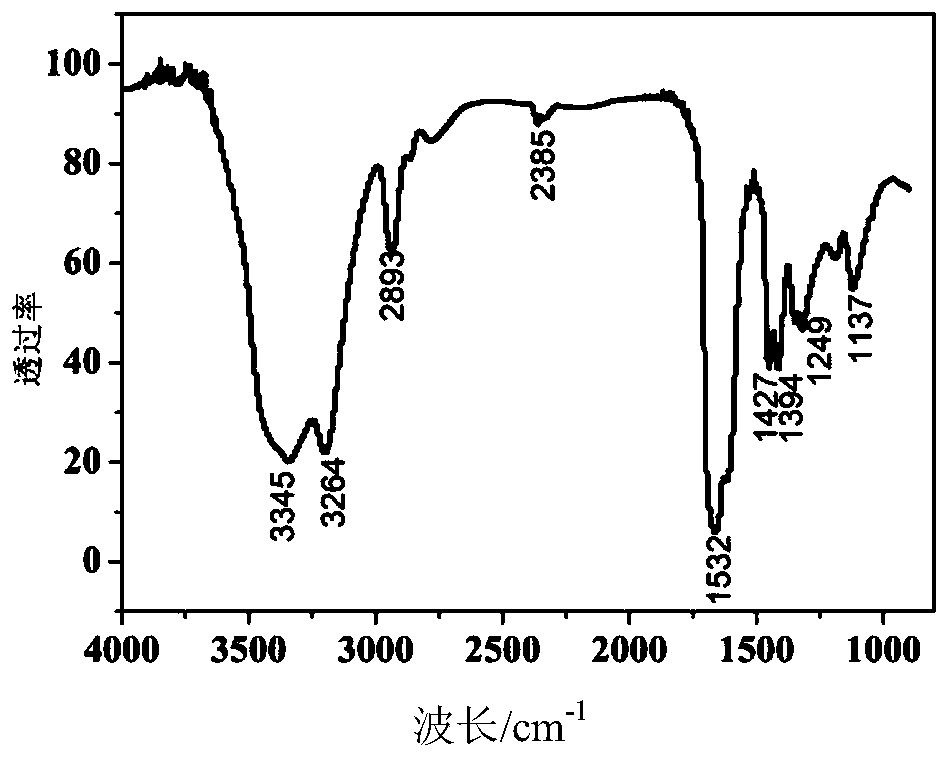

Surface-modified nano silicon dioxide as well as preparation method and application thereof

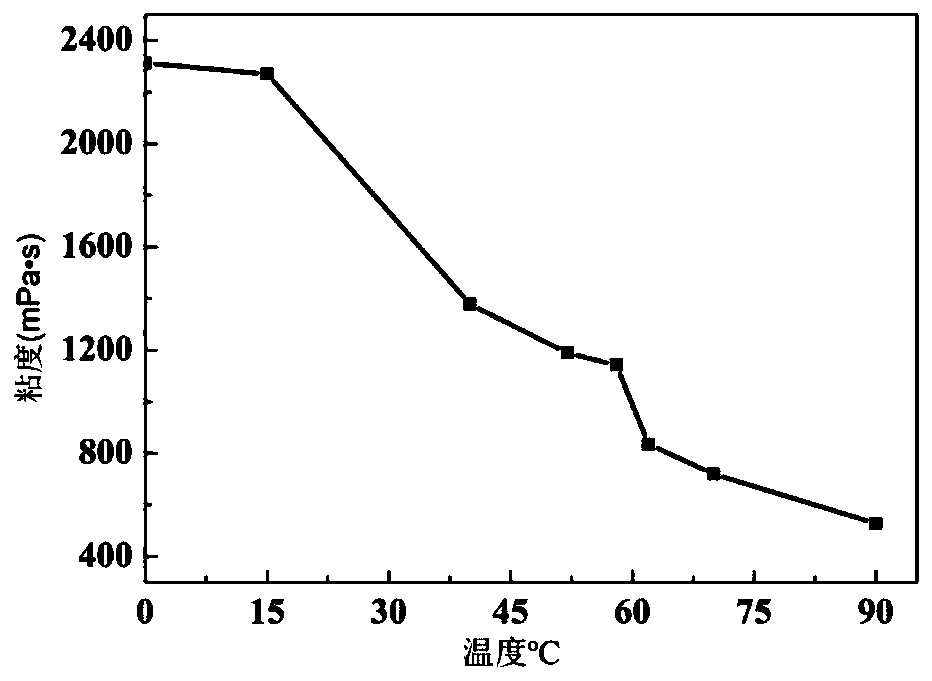

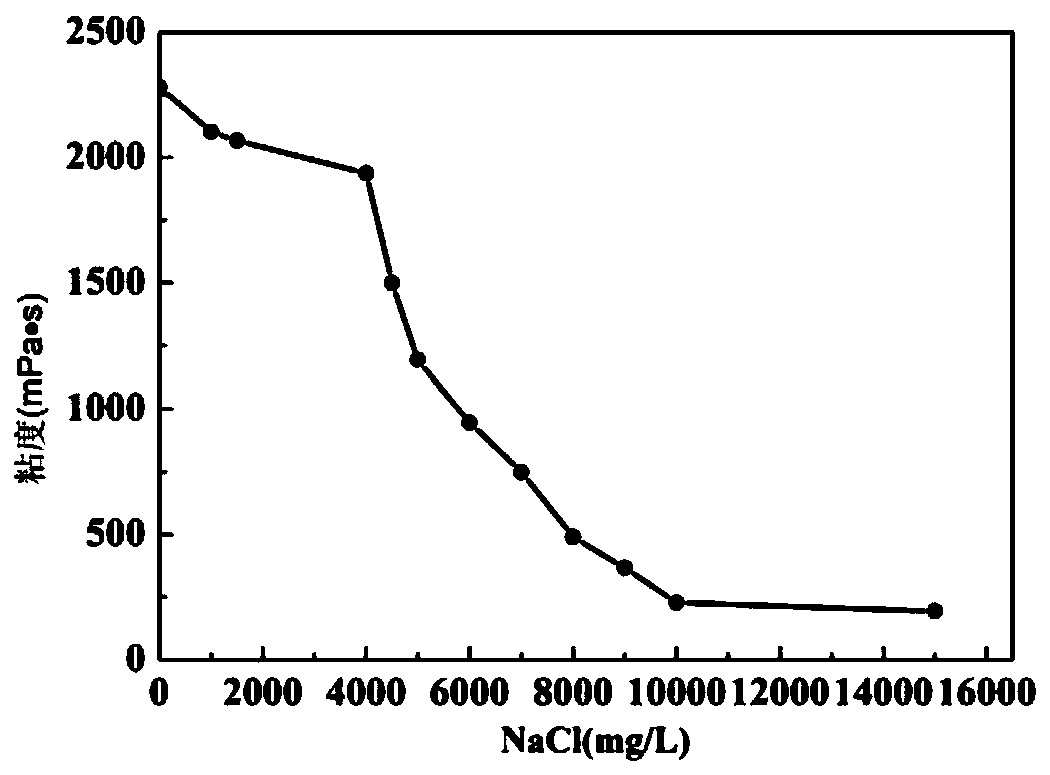

A technology of nano-silica and surface modification, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of low synthesis efficiency, long reaction time, high risk, etc., achieve low environmental pollution, and the preparation method Simple, EOR-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Get 0.5g nano silicon dioxide (particle size is 10nm, specific surface area is 150m 2 / g) As for the beaker, add 900mL of water and place it under normal temperature for mechanical stirring for 1h (rotating speed is 200r / min) to obtain dispersion A1; then take 50g of acrylamide and dissolve it in 80mL of water to obtain solution B1; mix dispersion A1 and Mix solution B1, pass nitrogen gas to remove dissolved oxygen for 10 minutes to obtain mixture C1; dissolve 0.4g potassium persulfate in 20mL water to obtain solution D1, place mixture C1 in an oil bath at a temperature of 55°C for heating treatment, and stir The speed is 200r / min. When the temperature of the thermometer in the solution reaches 40°C, heat up treatment. The temperature of the oil bath rises to 80°C. When the temperature of the thermometer reaches 45°C, add solution D1 and carry out polymerization reaction for 5 hours to obtain the surface modified polymer polyacrylamide Nano silica M1 (the mass content o...

Embodiment 2

[0051] Get 1.2g nano silicon dioxide (particle diameter is 60nm, specific surface area is 180m 2 / g) As for the beaker, add 900mL of water, place it under normal temperature and mechanically stir for 1h (rotating speed is 200r / min), to obtain dispersion A2; then take 40g of methacrylamide and dissolve it in 80mL of water to obtain solution B2; Mix A2 and solution B2, pass nitrogen to remove dissolved oxygen for 60 minutes, and obtain mixture C2; dissolve 0.5 g of potassium persulfate in 20 mL of water to obtain solution D2, and place mixture C2 in an oil bath at a temperature of 55 ° C for heating treatment , the stirring speed is 200r / min, when the temperature of the thermometer in the solution reaches 40°C, the temperature rise treatment is carried out, the temperature of the oil bath is raised to 80°C, and when the temperature of the thermometer reaches 60°C, the solution D2 is added to carry out the polymerization reaction for 4 hours, and the surface modified polymer poly...

Embodiment 3

[0053] Get 1.5g nano silicon dioxide (particle diameter is 110nm, specific surface area is 210m 2 / g) As for the beaker, add 900mL of water, place it under normal temperature and mechanically stir for 1h (rotating speed is 300r / min) to obtain dispersion A3; then take 45g of N-methylolacrylamide and dissolve it in 80mL of water to obtain solution B3; Dispersion A3 and solution B3 were mixed, and the dissolved oxygen was removed by nitrogen gas for 40 minutes to obtain mixture C3; 0.35 g of potassium persulfate was dissolved in 20 mL of water to obtain solution D3, and the mixture C3 was placed in an oil bath at a temperature of 55 ° C. Heating treatment, the stirring speed is 200r / min, when the temperature of the thermometer in the solution reaches 40°C, carry out the oil bath heating treatment, and raise it to 80°C, when the temperature of the thermometer reaches 80°C, add the solution D3 to carry out the polymerization reaction for 3 hours, and obtain the surface modified poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com