Method for preparing conductive polyaniline hydrogel based on composite oxidant

A technology of conductive polyaniline and composite oxidant, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve the problems of low yield, low conductivity and yield, and less products, and achieve the expansion of application range, The effect of improving specific capacitance and good stretchability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: the preparation method of PANI hydrogel

[0024] (1) Dissolve 4g of PVA-1750 (PVA-1750) in 16g of deionized water to prepare a PVA aqueous solution, stir and heat at 90°C until the PVA is completely dissolved.

[0025] (2) Dissolve 0.06 mmol (10.4 mg) of m-aminophenyl borate hydrochloride in 167 μL of concentrated hydrochloric acid, add to the solution of (1), and stir.

[0026] (3) After being dissolved, 1.2 mmol aniline (109 μL) was added to the solution in (2) above to obtain solution A;

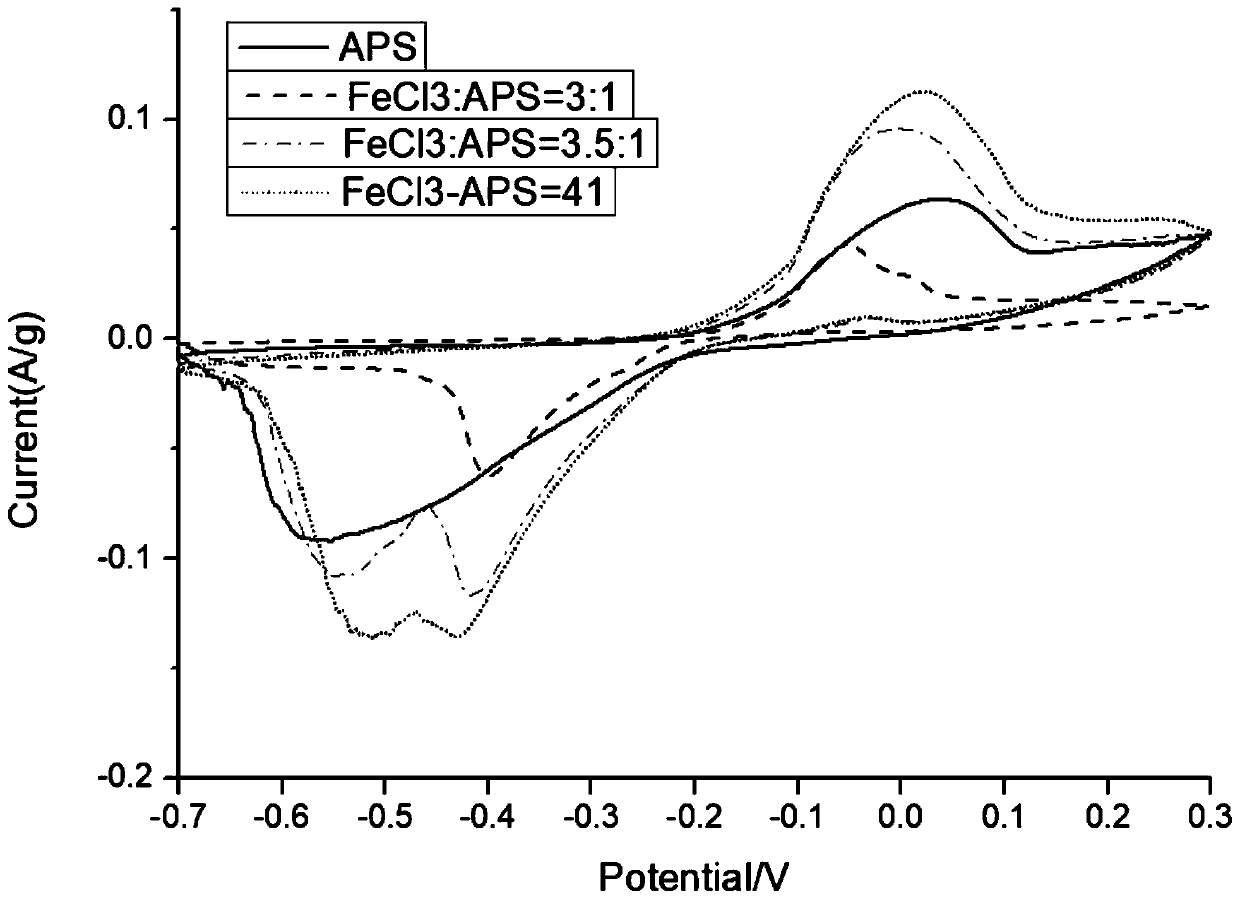

[0027] (4) 1.26mmol APS (288mg) and 1.74mmol FeCl 3 (468 mg) was dissolved in 500 μL of water to obtain solution B.

[0028] (5) Put solutions A and B in an ice bath, then add solution B to solution A, stir well, pour it into a mold, let it react at 0°C for 6 hours, and form a conductive hydrogel PANI hydrogel glue.

[0029] (6) Soak the PANI hydrogel in deionized water and wash it several times.

[0030] In this preferred system, the concentration of PVA is 5wt%...

Embodiment 2

[0031] Embodiment 2: the preparation of PANI hydrogel supercapacitor electrode

[0032] (1) Configure 6M HNO 3 , cut the carbon cloth into 1*1cm size, put it in 6M HNO 3 Medium, acidified for 24h.

[0033] (2) Weigh the acidified carbon cloth and record it.

[0034](3) Drop the PANI hydrogel on the acidified carbon cloth, let it grow at 0°C for 6 hours, weigh the mass again, subtract the previous mass from the latter mass to obtain the mass of the PANI hydrogel, Test samples of PANI hydrogels are available.

Embodiment 3

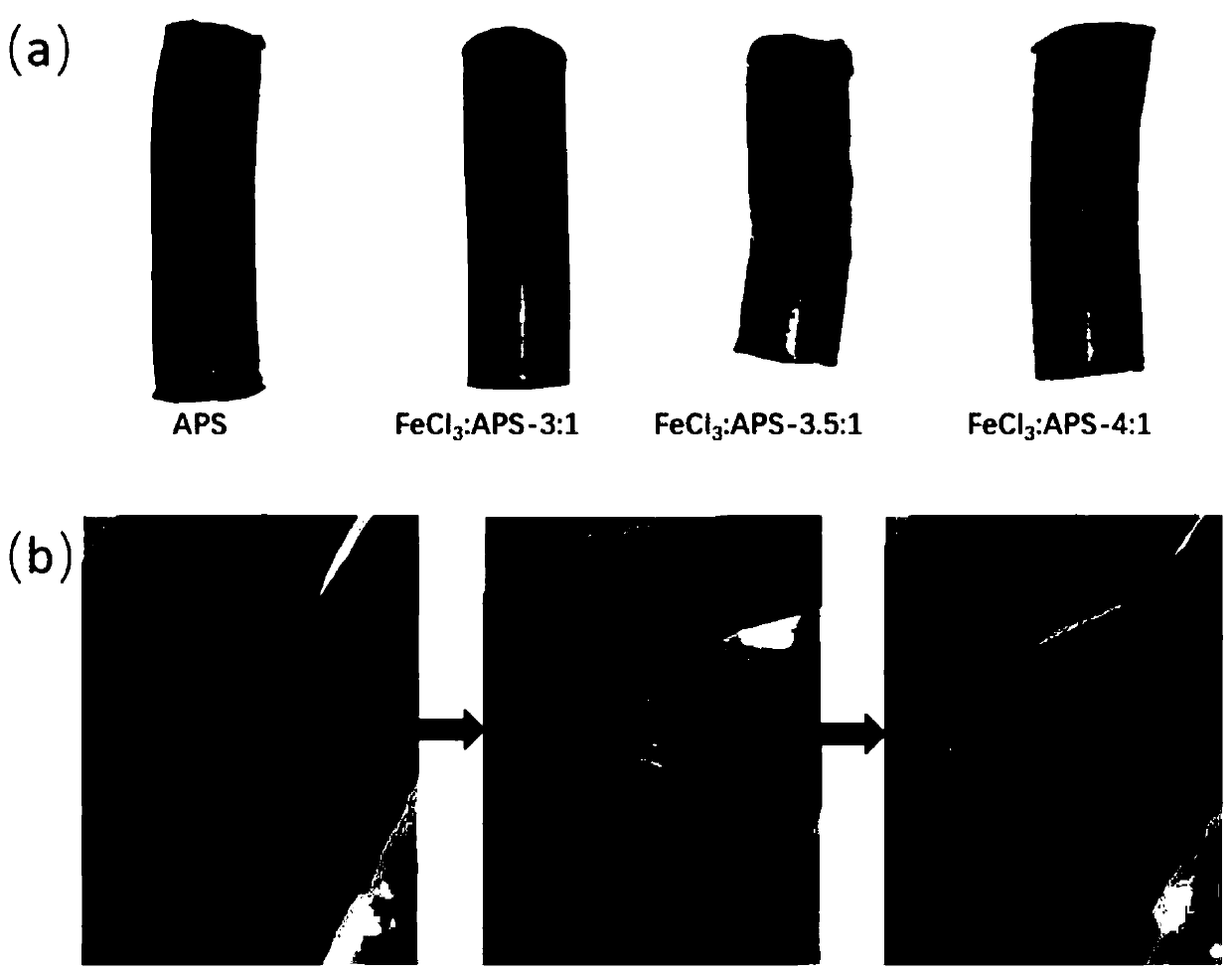

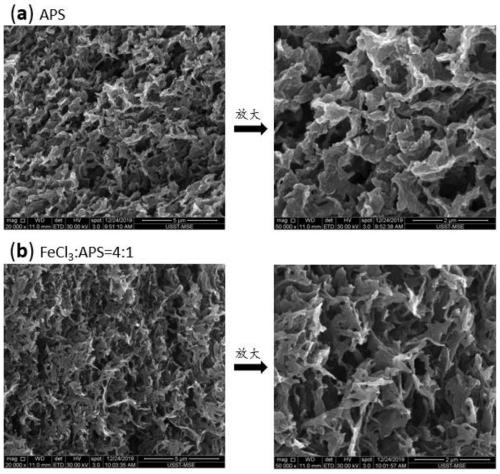

[0035] Embodiment 3: PANI hydrogel morphology characterization

[0036] Freeze-dry 4 kinds of PANI hydrogels prepared in different proportions for 12 hours. The obtained samples have no moisture. Take a piece of each cross-section and stick it on the conductive adhesive, spray gold, and carry out SEM test. The obtained results are as follows: figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com