Antifouling paint additive and preparation method thereof

A technology of antifouling coatings and additives, applied in the field of coatings, can solve the problems of increased cost, long time, complicated preparation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

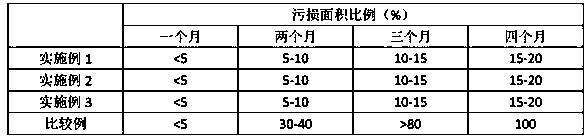

Examples

Embodiment 1

[0019] A preparation method of an antifouling paint additive for slow release of metal ions, comprising the steps of:

[0020] (1) Solution preparation, including: β-cyclodextrin aqueous solution A, cyclodextrin concentration is 20g / L; copper sulfate aqueous solution B, copper sulfate concentration is 1mol / L; sodium hydroxide aqueous solution C, sodium hydroxide concentration is 3mol / L; glucose solution D, glucose concentration is 3mol / L;

[0021] (2) Inject solutions B and C into A at the same time, mix, and apply ultrasonic vibration to the mixture with a vibration frequency of 20kHz to obtain suspension E;

[0022] (3) Under continuous ultrasonic vibration, heat suspension E to 80°C, inject solution D, keep warm for 20 minutes, filter and dry to obtain cyclodextrin-coated cuprous oxide composite material.

Embodiment 2

[0024] A preparation method of an antifouling paint additive for slow release of metal ions, comprising the steps of:

[0025] (1) Solution preparation, including: α-cyclodextrin aqueous solution A, cyclodextrin concentration is 30g / L; copper sulfate aqueous solution B, copper sulfate concentration is 1mol / L; sodium hydroxide aqueous solution C, sodium hydroxide concentration is 4mol / L; glucose solution D, glucose concentration is 4mol / L;

[0026] (2) Inject solutions B and C into A at the same time, mix, and apply ultrasonic vibration to the mixture with a vibration frequency of 30kHz to obtain suspension E;

[0027] (3) Under continuous ultrasonic vibration, heat suspension E to 90°C, inject solution D, keep warm for 30 minutes, filter and dry to obtain cyclodextrin-coated cuprous oxide composite material.

Embodiment 3

[0029] A preparation method of an antifouling paint additive for slow release of metal ions, comprising the steps of:

[0030] (1) Solution preparation, including, γ-cyclodextrin aqueous solution A, cyclodextrin concentration is 40g / L; copper sulfate aqueous solution B, copper sulfate concentration is 2mol / L; sodium hydroxide aqueous solution C, sodium hydroxide concentration is 6mol / L; glucose solution D, glucose concentration is 5mol / L;

[0031] (2) Inject solutions B and C into A at the same time, mix, and apply ultrasonic vibration to the mixture with a vibration frequency of 40kHz to obtain suspension E;

[0032] (3) Under continuous ultrasonic vibration, heat suspension E to 100°C, inject solution D, keep warm for 40 minutes, filter and dry to obtain cyclodextrin-coated cuprous oxide composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com