Optical coating for projection screen

An optical coating, projection screen technology, applied in optics, polyether coatings, polyester coatings, etc., can solve the problems of environmental pollution, threat to the health of workers, difficult to obtain display effects, etc., achieve image color saturation, improve contrast, The effect of reducing gas pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

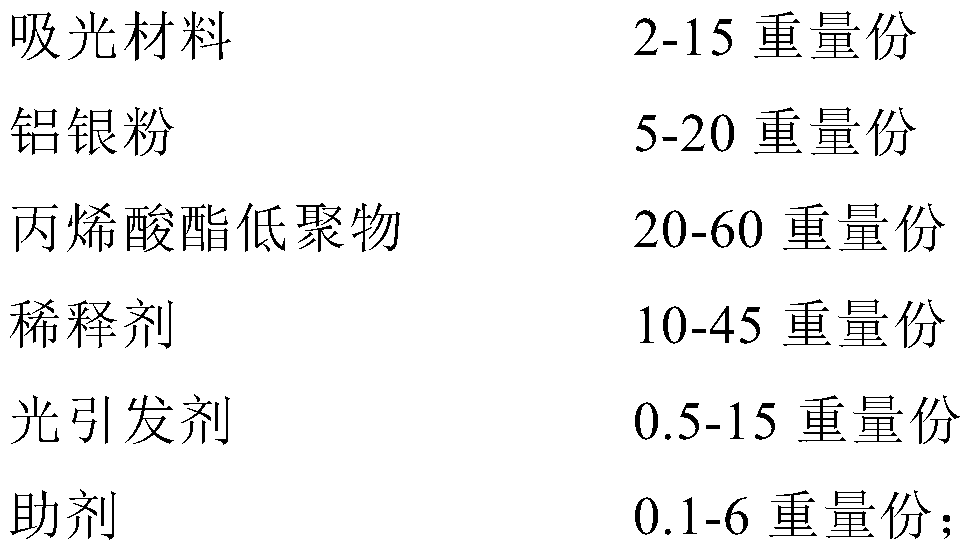

[0055] In this embodiment, the specific composition and usage ratio of each component of the projection screen optical coating are:

[0056]

[0057]

[0058] A preparation method of the projection screen optical coating of this embodiment is introduced below, and the preparation method includes the following steps:

[0059] S11: uniformly mixing 1 / 2 of the total weight of the acrylate oligomer with the light-absorbing material to form a first solution;

[0060] S12: Add 1 / 2 total weight of acrylate oligomer, aluminum silver powder, diluent, photoinitiator, cosolvent, wetting and dispersing agent, anti-sedimentation thixotropic agent, leveling agent and Mix well after the defoamer.

[0061] In the above S11, the acrylate oligomer and the light-absorbing material may be uniformly mixed by grinding or by high-speed shear stirring. Preferably, the stirring speed is 2000-3000r / min. The purpose of adding the acrylate oligomer twice is to make the acrylate oligomer mix evenl...

Embodiment 2

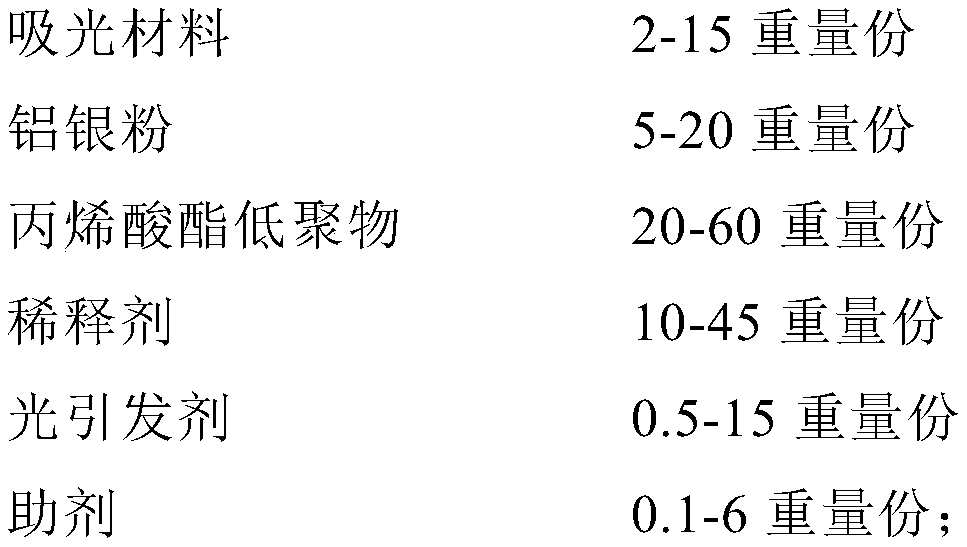

[0068] In this embodiment, the specific composition and usage ratio of each component of the projection screen optical coating are:

[0069]

[0070] The projection screen optical coating described in this embodiment can be prepared by the preparation method described in Embodiment 1, which will not be repeated here.

[0071] The components in this example are mixed to prepare an optical coating for a projection screen, which is used to produce a Fresnel microstructured optical screen. The achievable effects are: contrast ratio 8.5, center gain 0.95.

Embodiment 3

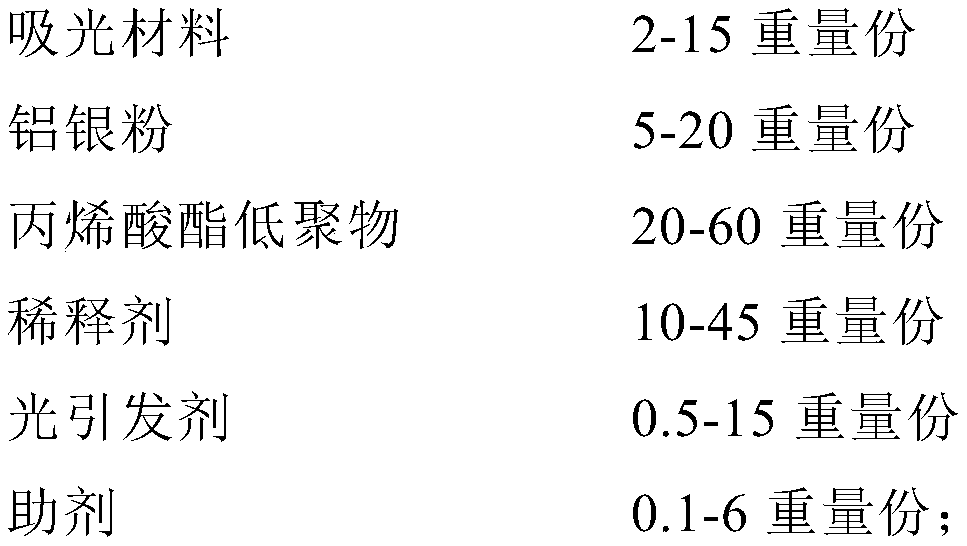

[0073] In this embodiment, the specific composition and usage ratio of each component of the projection screen optical coating are:

[0074]

[0075] The projection screen optical coating described in this embodiment can be prepared by the preparation method described in Embodiment 1, which will not be repeated here.

[0076]The components in this example are mixed to prepare an optical coating for a projection screen, which is used to produce a Fresnel microstructured optical screen. The achievable effects are: contrast ratio 9.5, center gain 1.0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Angle of view | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com