Solvent-free polyurethane binder for colored pavements and preparation method thereof

A solvent-free polyurethane and adhesive technology, applied in the direction of polyurea/polyurethane adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problem of low tensile strength, price increase, adhesive products Supply price fluctuations and other issues, to achieve the effect of ensuring timeliness, improving tensile strength, and having a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

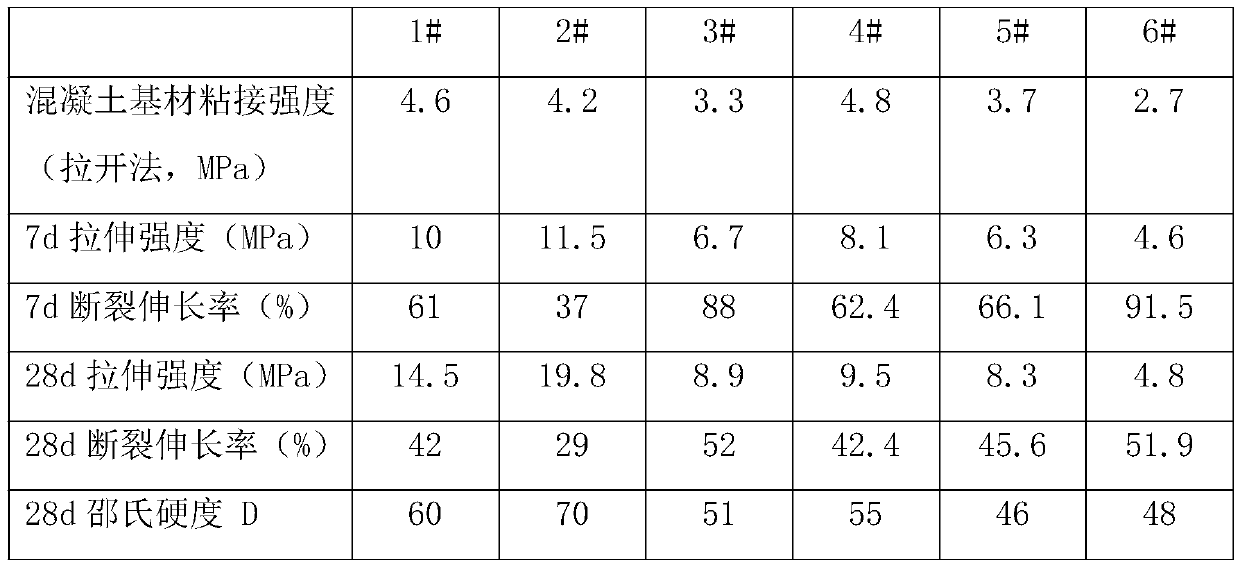

Examples

Embodiment 1

[0027] A solvent-free polyurethane binder for colored pavements, comprising a main agent and a curing agent, the main agent takes raw materials according to the weight percentage of the following components: soybean oil polyester polyol (molecular weight 2500, hydroxyl value 330, functional 5) 24%, soybean oil polyester polyol (molecular weight 1200, hydroxyl value 130, functionality 2.5) 30%, 1,4-bis-sec-butylaminobenzene 1%, diisopropylnaphthalene 4%, zeolite powder 10% , Dispersant BYKP104 0.5%, silicon micropowder 29.5%, iron oxide red powder 1%.

[0028] Further improved, the curing agent contains 50% polymethylene polyphenylisocyanate PAPI (NCO=32%, functionality 2.7) and 50% modified MDI prepolymer (NCO=23%, functionality 2).

[0029] Further improved, the preparation method of the solvent-free polyurethane adhesive for colored pavement comprises the following steps:

[0030] S1: Prepare the main ingredient: combine soybean oil polyester polyol (molecular weight 2500, ...

Embodiment 2

[0040] A solvent-free polyurethane binder for colored pavements, comprising a main agent and a curing agent, the main agent takes raw materials according to the weight percentage of the following components: soybean oil polyester polyol (molecular weight 2500, hydroxyl value 330, functional 5) 35%, soybean oil polyester polyol (molecular weight 1200, hydroxyl value 130, functionality 2.5) 20%, 1,4-bis-sec-butylaminobenzene 1%, diisopropylnaphthalene 4%, zeolite powder 10% , Dispersant BYKP104 0.5%, silicon micropowder 29.5%, iron oxide red powder 1%.

[0041] Further improved, the curing agent contains 50% polymethylene polyphenylisocyanate PAPI (NCO=32%, functionality 2.7) and 50% modified MDI prepolymer (NCO=23%, functionality 2).

[0042] Further improved, the preparation method of the solvent-free polyurethane adhesive for colored pavement comprises the following steps:

[0043] S1: Prepare the main ingredient: combine soybean oil polyester polyol (molecular weight 2500, ...

Embodiment 3

[0053] A solvent-free polyurethane adhesive for colored pavements, comprising a main agent and a curing agent, the main agent includes the following ingredients raw materials: soybean oil polyester polyol (molecular weight 2500, hydroxyl value 330, functionality 5), soybean oil Polyester polyol (molecular weight 1200, hydroxyl value 130, functionality 2.5), diisopropylnaphthalene, dispersant BYKP104, zeolite powder, silicon micropowder, iron oxide red powder.

[0054] Further improved, take raw material according to the weight percent of following each composition: soybean oil polyester polyol (molecular weight 2500, hydroxyl value 330, functionality 5) 15%, soybean oil polyester polyol (molecular weight 1200, hydroxyl value 130, Functionality 2.5) 40%, diisopropylnaphthalene 4%, zeolite powder 10%, dispersant BYKP104 0.5%, silicon micropowder 29.5%, iron oxide red powder 1%.

[0055] Further improved, the curing agent contains 50% polymethylene polyphenylisocyanate PAPI (NCO=...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com