Chain pin shaft carbonitriding process

A technology of carbonitriding and pin shaft, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problem of affecting product durability, surface hardness and wear resistance cannot be further improved, and high hardness requirements problems, to achieve the effect of eliminating internal stress, breaking through technical bottlenecks, and high fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

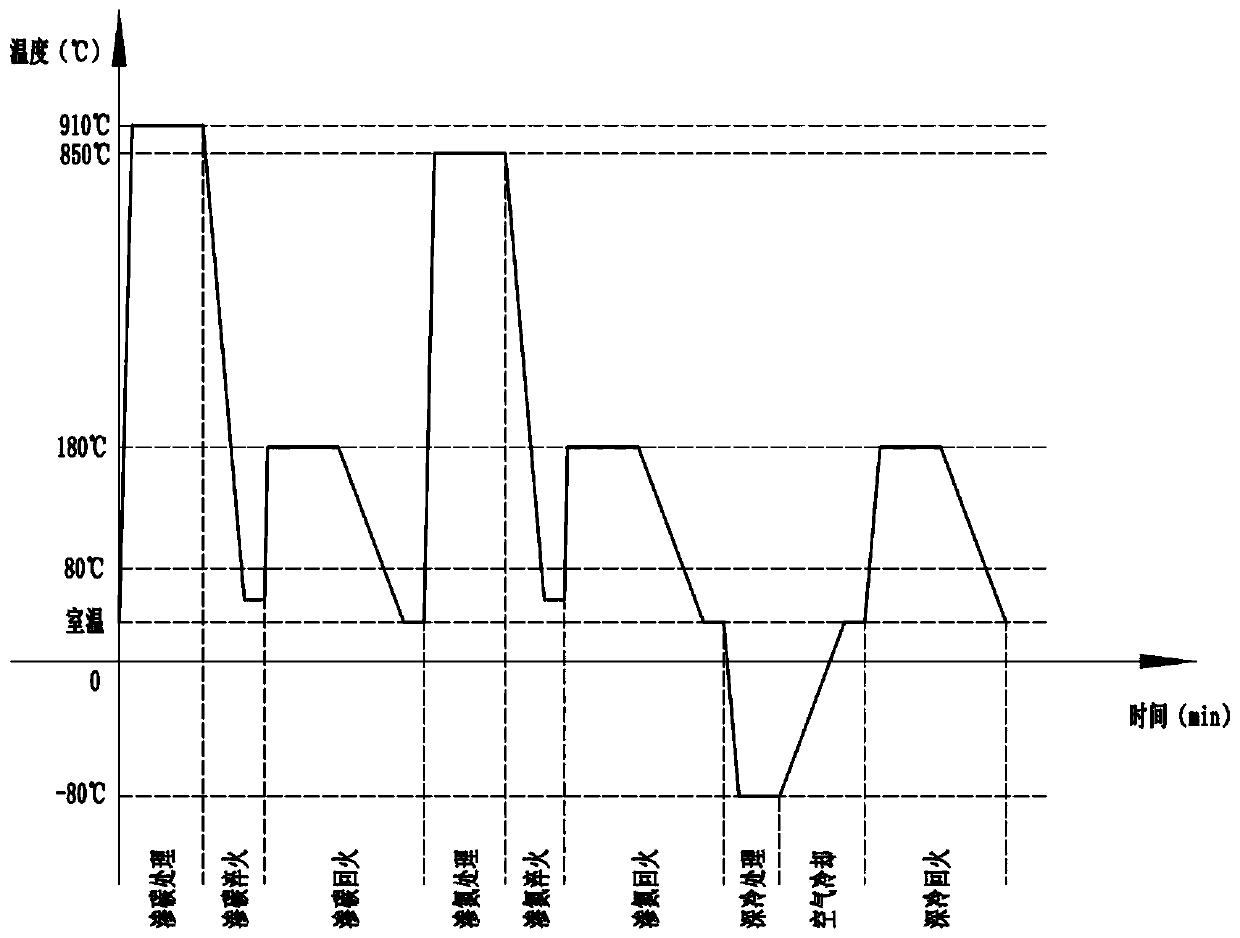

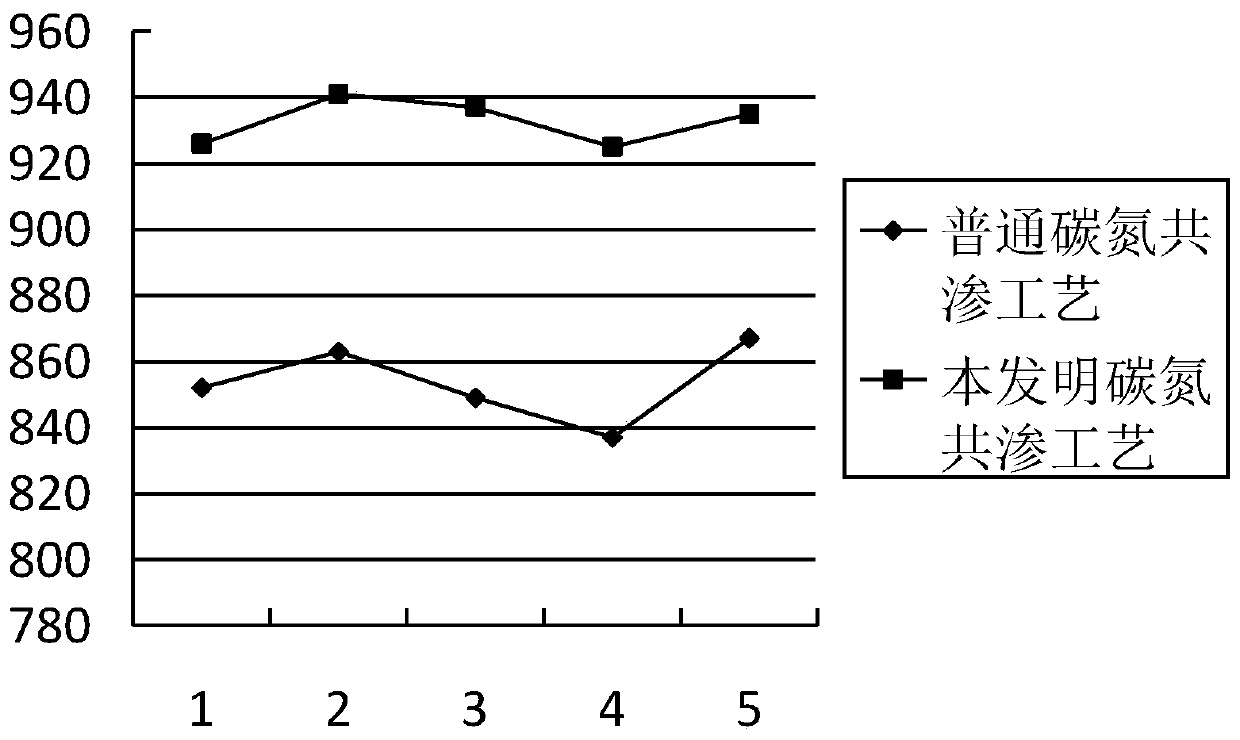

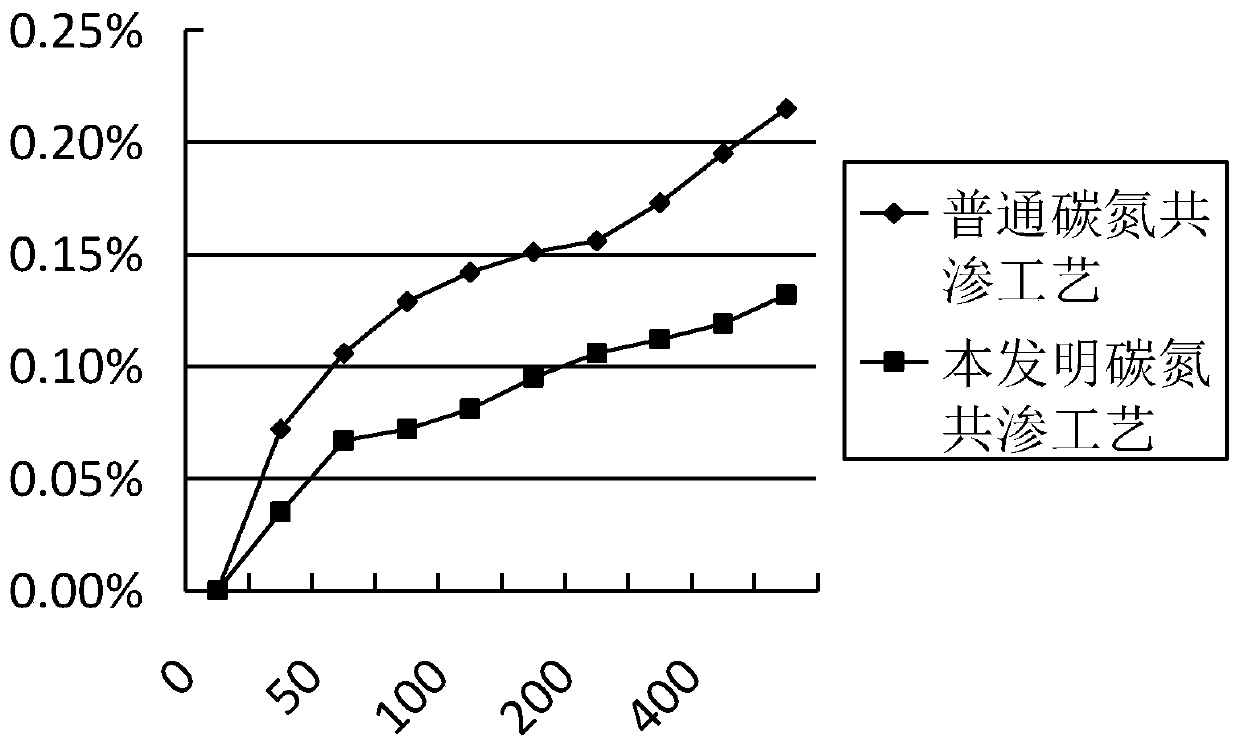

[0023] Embodiment 1: chain pin carbonitriding process, comprising the following steps:

[0024] Step A, carburizing treatment: carburizing the workpiece in a mesh belt furnace or a converter, the carburizing medium is methanol and kerosene, the heating temperature is 895-925°C, and the holding time is 35-45min;

[0025] Step B, carburizing and quenching: after the carburizing treatment holding time is reached, the workpiece is rapidly quenched with quenching oil at 20-80°C;

[0026] Step C, carburizing and tempering: heat the workpiece that has been carburized and quenched to 170-190°C and keep it warm for 170-190min to perform low-temperature tempering;

[0027] Step D, nitriding treatment: carry out nitriding treatment on the workpiece in a mesh belt furnace or a converter, the nitriding medium is ammonia gas, the heating temperature is 835-865°C, and the holding time is 40-60 minutes;

[0028] Step E, nitriding and quenching: after the nitriding treatment holding time is r...

Embodiment 2

[0038] Embodiment 2: chain pin carbonitriding process, comprising the following steps:

[0039] Step A, carburizing treatment: carburizing the workpiece in a mesh belt furnace, the carburizing medium is methanol and kerosene, wherein the input flow rate of the carburizing medium methanol is 2.0mL / min, and the input flow rate of the carburizing medium kerosene is 3.0 mL / min, heating temperature 895°C, holding time 35min;

[0040] Step B, carburizing and quenching: after the carburizing treatment holding time is reached, the workpiece is rapidly quenched with quenching oil at 20°C;

[0041] Step C, carburizing and tempering: heat the workpiece that has been carburized and quenched to 170°C and keep it warm for 170min to perform low-temperature tempering;

[0042] Step D, nitriding treatment: carry out nitriding treatment on the workpiece in a mesh belt furnace, the nitriding medium is ammonia gas, wherein the flow rate of ammonia gas into the nitriding medium is 350L / h, the hea...

Embodiment 3

[0048] Embodiment 3: chain pin shaft carbonitriding process, comprises the following steps:

[0049]Step A, carburizing treatment: carry out carburizing treatment to workpiece in converter, carburizing medium is methanol and kerosene, wherein the input flow rate of carburizing medium methanol is 2.5mL / min, the input flow rate of carburizing medium kerosene is 3.5mL / min min, heating temperature 925°C, holding time 45min;

[0050] Step B, carburizing and quenching: after the carburizing treatment holding time is reached, the workpiece is rapidly quenched with 80°C quenching oil;

[0051] Step C, carburizing and tempering: heat the workpiece that has been carburized and quenched to 190°C and keep it warm for 190min to perform low-temperature tempering;

[0052] Step D, nitriding treatment: carry out nitriding treatment on the workpiece in the converter, the nitriding medium is ammonia gas, wherein the flow rate of ammonia gas into the nitriding medium is 400L / h, the heating temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com