Positive electrode material coated with phosphorus-containing compound and preparation method of positive electrode material

A technology of positive electrode materials and compounds, applied in the field of positive electrode materials coated with phosphorus-containing compounds and its preparation, can solve the problems of reducing the capacity of positive electrode materials, uneven coating and mixing, and difficult control of the coating amount, and achieve low material cost, The effect of wide equipment operation window and less material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

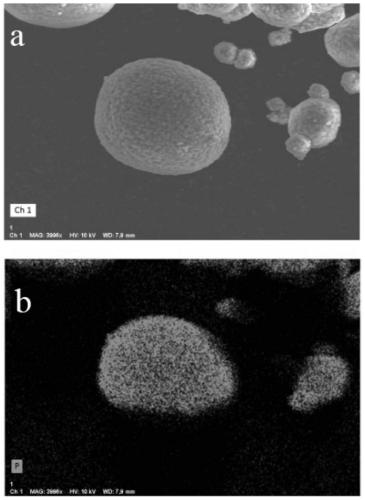

[0054] In this example, phosphorus oxide-coated high-nickel ternary material is taken as an example:

[0055] S1, put the high-nickel ternary material into the reaction chamber of the atomic layer deposition equipment, set the reaction temperature to 250°C, and keep it for 2 hours;

[0056] S2, in this embodiment, trimethyl phosphate is used as precursor A, and trimethyl phosphate is passed into the reaction chamber, the pressure is set to 5torr, and the reaction time is 50s;

[0057] S3, pass into N 2 Excessive trimethyl phosphate and by-products are purged, and the purging time is 50s;

[0058] S4, this embodiment uses H 2 O is used as the precursor B, and H is introduced into the reaction chamber 2 O, the pressure is set to 5torr, and the response time is 50s;

[0059] S5, pass into N 2 to purge the excess H 2 O and by-products, the purge time is 50s;

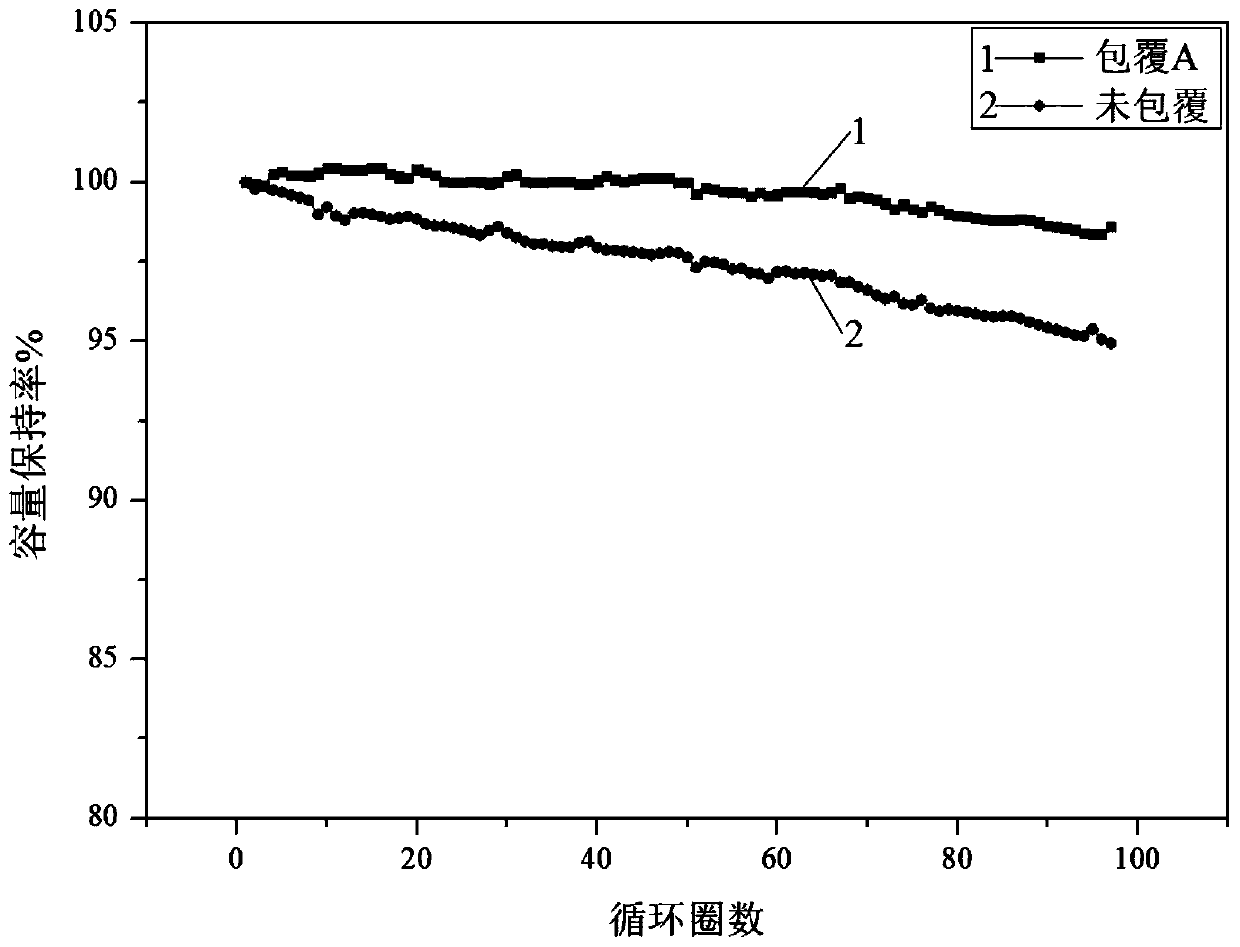

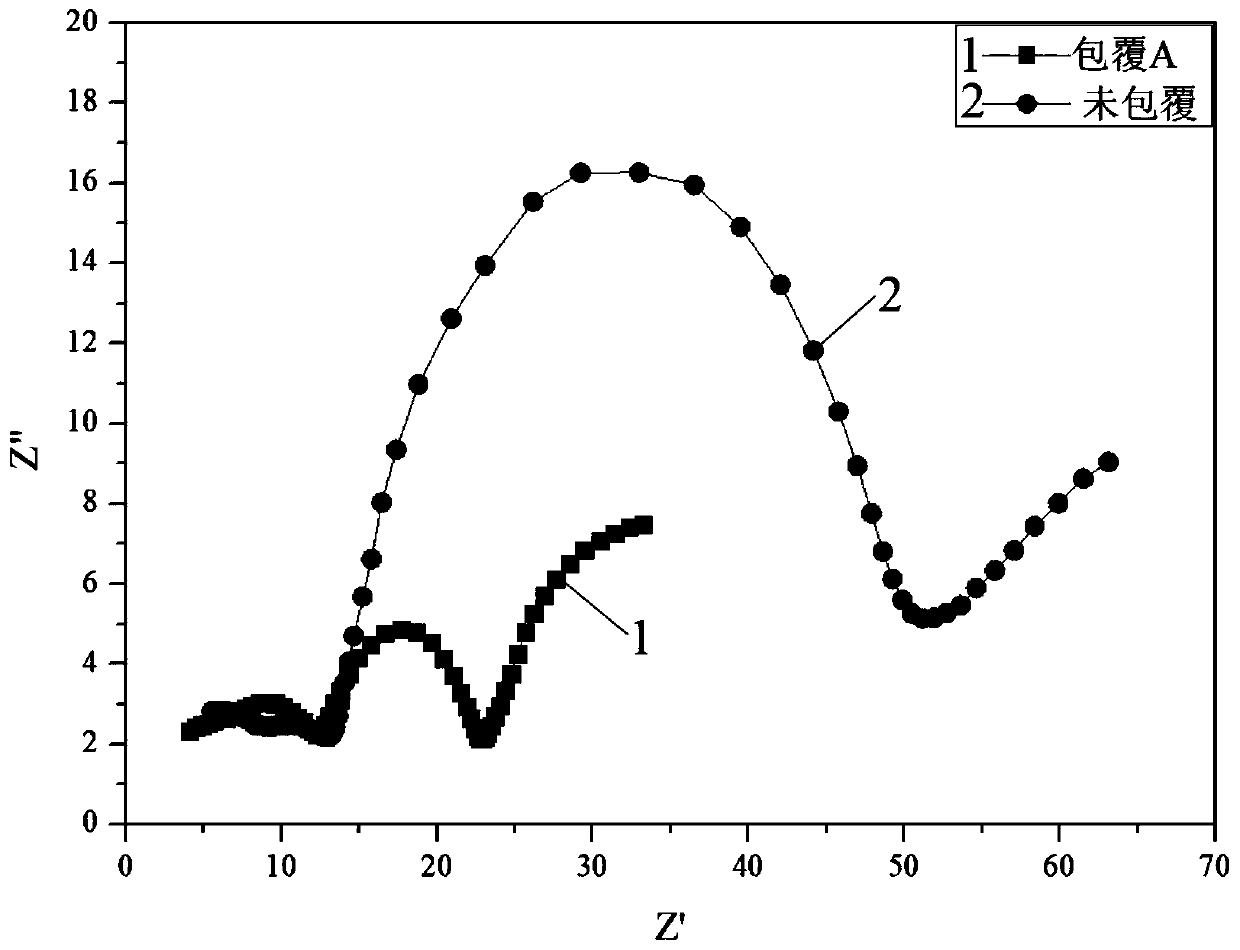

[0060] S6, repeating steps S2 to S5 50 times to obtain a positive electrode material uniformly coated with 10nm pho...

Embodiment 2

[0063] This example takes phosphorus oxide coated lithium cobalt oxide material as an example:

[0064] S1, put the lithium cobalt oxide material into the reaction chamber of the atomic layer deposition equipment, set the reaction temperature to 300°C, and keep the time for 2h;

[0065] S2, in this embodiment, trimethyl phosphate is used as precursor A, and trimethyl phosphate is passed into the reaction chamber, the pressure is set to 5torr, and the reaction time is 50s;

[0066] S3, pass into N 2 Excessive trimethyl phosphate and by-products are purged, and the purging time is 50s;

[0067] S4, this embodiment uses O 3 As precursor B, feed O into the reaction chamber 3 , the pressure is set to 5torr, and the response time is 50s;

[0068] S5, pass into N 2 to purge the excess O 3 and by-products, the purge time is 50s;

[0069] S6, repeating steps S2 to S5 50 times to obtain a positive electrode material uniformly coated with 10nm phosphorus oxide;

[0070] S7, the p...

Embodiment 3

[0072] This example takes phosphorus oxide-coated high-nickel ternary material as an example:

[0073] S1, select the high-nickel ternary material coated with Al by mechanical fusion method and put it into the reaction chamber of the atomic layer deposition equipment, set the reaction temperature to 200°C, and the holding time to 2.0h;

[0074] S2, in this embodiment, trimethyl phosphate is used as precursor A, and trimethyl phosphate is passed into the reaction chamber, the pressure is set to 5torr, and the reaction time is 50s;

[0075] S3, pass into N 2 Excessive trimethyl phosphate and by-products are purged, and the purging time is 50s;

[0076] S4, this embodiment uses O 3 As precursor B, feed O into the reaction chamber 3 , the pressure is set to 5torr, and the response time is 50s;

[0077] S5, pass into N 2 to purge the excess O 3 and by-products, the purge time is 50s;

[0078] S6, repeating steps S2 to S5 50 times to obtain a positive electrode material unifo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com