Boron-doped nickel-cobalt-manganese positive electrode material and preparation method thereof

A cathode material, nickel-cobalt-manganese technology, used in battery electrodes, structural parts, electrical components, etc., to improve high-temperature cycle stability, reduce cation mixing, and reduce residual lithium content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

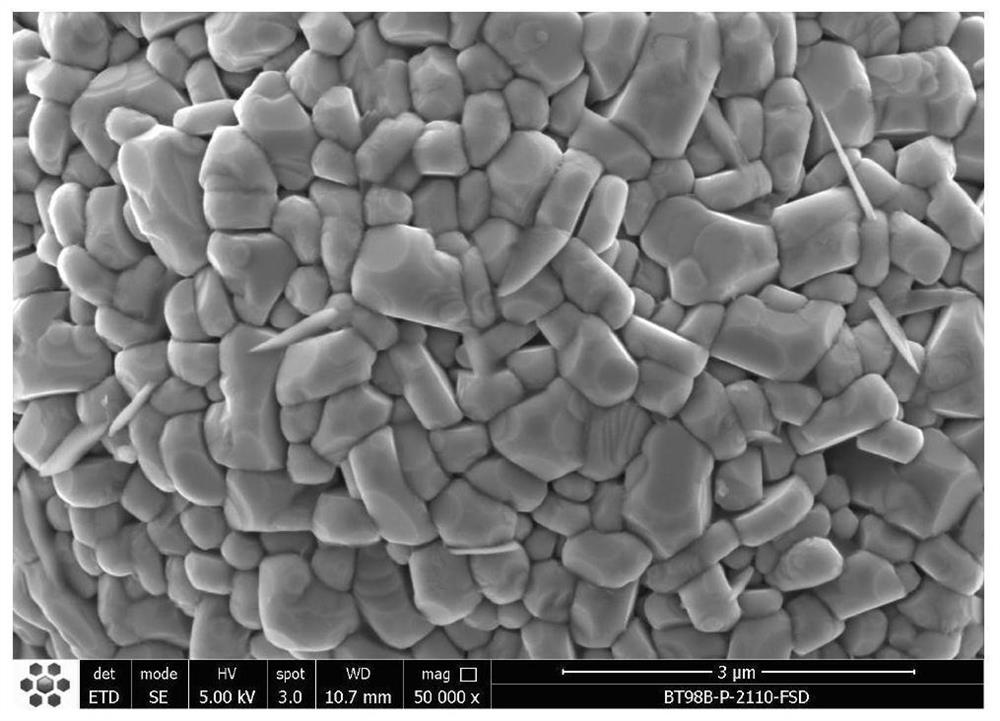

[0035] A boron-doped nickel-cobalt-manganese cathode material, the general formula of the matrix is Li 1.00 Ni 0.845 Co 0.07 Mn 0.05 Mg 0.01 Sn 0.005 B 0.0 2 O 2.00 , the secondary particle size is D10=9.15 μm, D50=13.04 μm, D90=15.40 μm, and the value of the secondary particle size is obtained by the Malvern 3000 laser particle size analyzer. According to the Scherrer formula: D=Kγ / Bcosθ (K is the Scherrer constant, take K=0.89, γ is the X-ray wavelength=0.15418nm, B is the width of the half-peak width of the crystallite size, θ is the Bragg angle), using XRD The boron-doped positive electrode material was analyzed, and the crystallite size D=52.4 nm was calculated using the Scherrer formula according to the analysis result (the peak of the 104 crystal plane).

[0036] The method for preparing boron-doped nickel-cobalt-manganese positive electrode material comprises the following steps:

[0037] (1) The high nickel cathode material precursor Ni 0.88 Co 0.07 Mn 0...

Embodiment 2

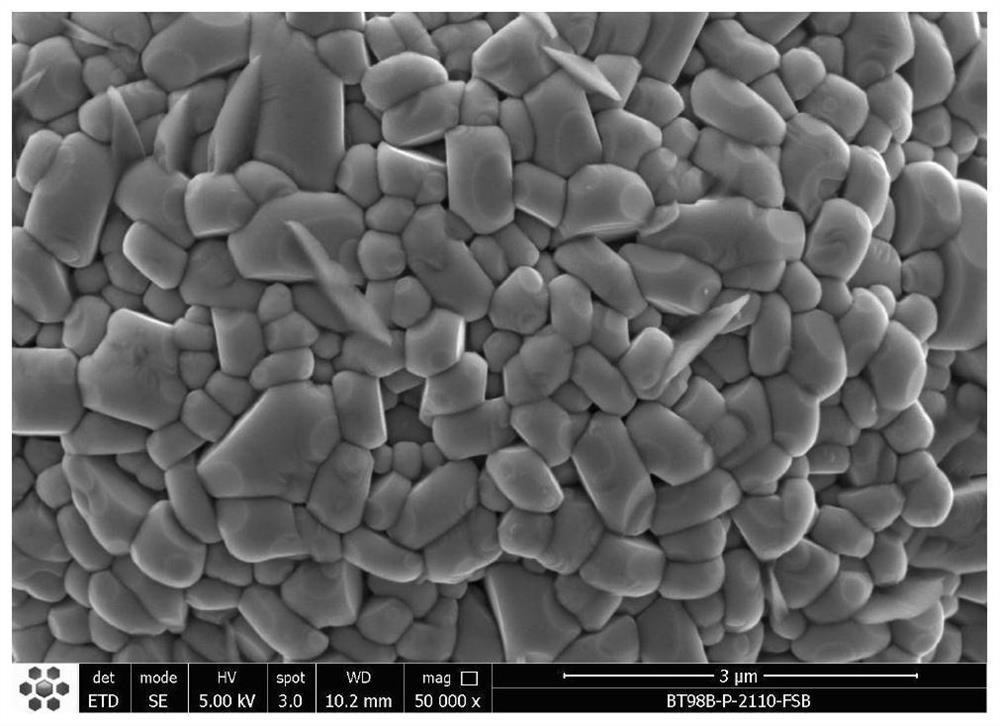

[0041] A boron-doped nickel-cobalt-manganese cathode material, the general formula of the matrix is Li 1.00 Ni 0.867 Co 0.05 Mn 0.05 Al 0.01 Sn 0.003 B 0.0 2 O 2.00 , the secondary particle size D10=10.32 μm, D50=13.56 μm, D90=16.41 μm, the value of the secondary particle size is obtained by the Malvern 3000 laser particle size analyzer. Its crystallite size is calculated by the Scherrer formula to obtain D=54.6nm.

[0042] The method for preparing boron-doped nickel-cobalt-manganese positive electrode material comprises the following steps:

[0043] (1) The high nickel cathode material precursor Ni 0.90 Co 0.05 Mn 0.05 (OH) 2 , LiOH·H 2 O, AlB 2 , SnO 2 Put into a high-speed mixer for mixing at a molar ratio of 1:1.03:0.01:0.003, the rotation speed is 1500rpm / min, and after high-speed mixing for 30min, a mixed material is obtained, and the mixed material is placed in a sintering furnace. The temperature was raised to 500°C at a heating rate of 1 / min, kept si...

Embodiment 3

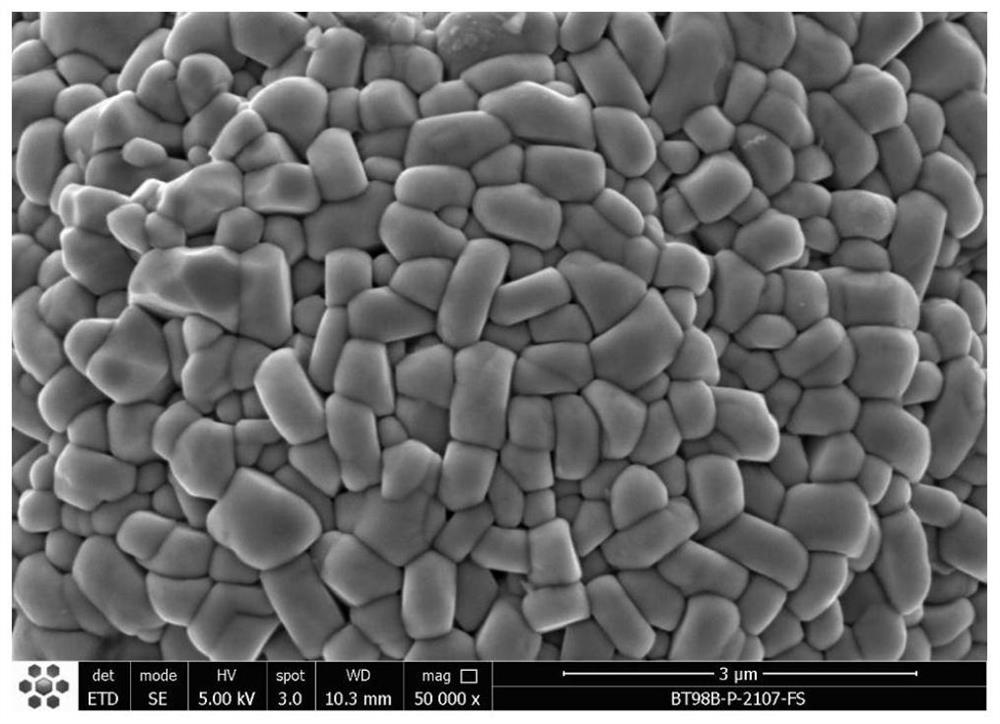

[0047] A boron-doped nickel-cobalt-manganese cathode material, the general formula of the matrix is Li 1.00 Ni 0.848 Co 0.06 Mn 0.06 Mg 0.01 Mo 0.002 B 0.0 2 O 2.00 , the secondary particle size D10=9.92 μm, D50=13.32 μm, D90=15.22 μm, the value of the secondary particle size is obtained by the Malvern 3000 laser particle size analyzer. Its crystallite size is calculated by the Scherrer formula to obtain D=62.6nm.

[0048] The method for preparing boron-doped nickel-cobalt-manganese positive electrode material comprises the following steps:

[0049] (1) The high nickel cathode material precursor Ni 0.88 Co 0.06 Mn 0.06 (OH) 2 , LiOH·H 2 O, MgB 2 , MoO 3 Put into a high-speed mixer for mixing at a molar ratio of 1:1.06:0.01:0.002, the speed is 1500rpm / min, and after high-speed mixing for 30min, a mixed material is obtained, and the mixed material is placed in a sintering furnace. The temperature was raised to 500°C at a heating rate of 1 / min, kept sintered for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com