Method for eliminating residual lithium by lithium transition metal oxide and application thereof

A lithium transition metal, non-metal oxide technology, applied in chemical instruments and methods, nickel compounds, cobalt compounds, etc., can solve problems such as electrochemical performance degradation, surface structure damage, material structure deterioration, etc., to achieve improved cycle performance, Effects of low surface lithium residues, good cycle performance and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

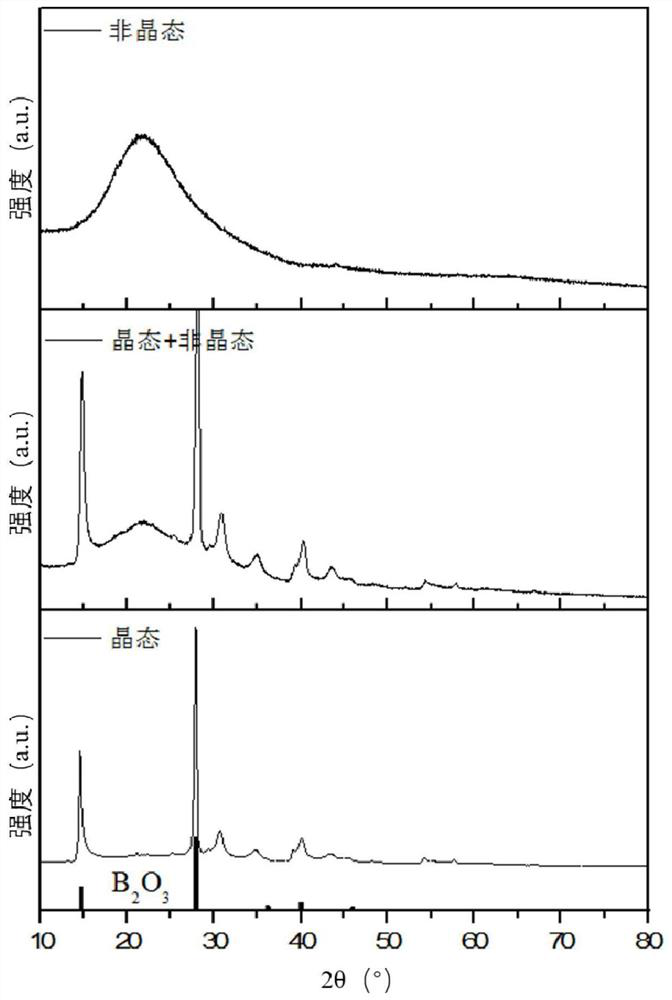

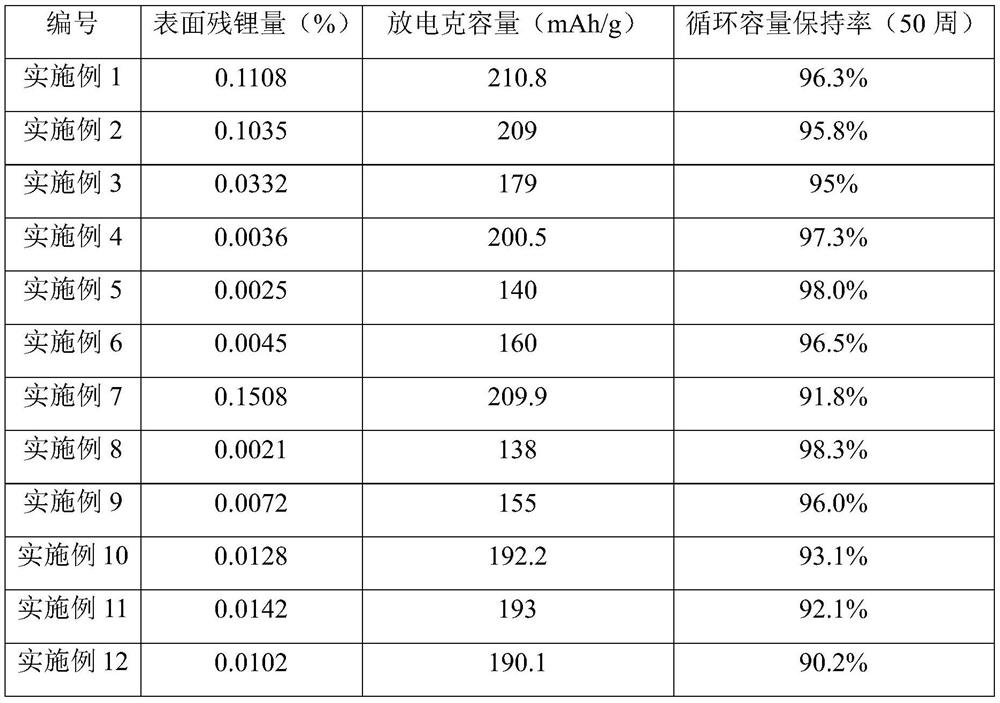

[0050] This embodiment provides a lithium transition metal oxide with a crystalline surface layer, the lithium transition metal oxide is high-nickel-nickel-cobalt lithium manganese oxide, and the crystalline surface layer is composed of crystalline boron oxide, aluminum oxide, titanium oxide, Composed of manganese oxide and trace residual lithium. The mass ratio percentage of the crystalline surface layer to the high-nickel-nickel-cobalt lithium manganese oxide is about 0.35%. Among them, titanium oxide, aluminum oxide and manganese oxide account for about 15% of the mass fraction of the crystalline surface layer, and the rest is mainly about 85% of crystalline boron oxide and trace residual lithium absorbed by high-nickel-nickel-cobalt lithium manganese oxide.

[0051] This lithium complex is obtained by absorbing residual lithium through lithium-absorbing agent of high-nickel-nickel-cobalt manganese oxide, and the specific steps include:

[0052] (1) Uniformly mix amorphous...

Embodiment 2

[0057] This embodiment provides a lithium transition metal oxide with a crystalline surface layer, the lithium transition metal oxide is lithium nickel cobalt aluminate, and the crystalline surface layer is composed of crystalline silicon oxide, cobalt oxide, titanium oxide, and yttrium oxide. and trace amounts of residual lithium. The mass ratio percentage of the crystalline surface layer to lithium nickel cobalt aluminate is about 3%. Among them, cobalt oxide, titanium oxide, and yttrium oxide account for about 20% of the mass fraction of the crystalline surface layer, and the rest is mainly about 80% of crystalline silicon oxide and trace residual lithium absorbed by nickel-cobalt lithium aluminate.

[0058] This lithium complex is obtained by absorbing residual lithium through a lithium absorbing agent through nickel-cobalt-aluminate lithium, and the specific steps include:

[0059] (1) Uniformly mix amorphous silicon oxide, cobalt oxide, titanium oxide, yttrium oxide and...

Embodiment 3

[0063] This embodiment provides a lithium transition metal oxide with a crystalline surface layer, the lithium transition metal oxide is low nickel nickel cobalt lithium manganese oxide, the crystalline surface layer is composed of crystalline phosphorus oxide, magnesium oxide, zirconium oxide and Composed of tungsten oxide and trace residual lithium. The mass ratio percentage of the crystalline surface layer to the low-nickel-nickel-cobalt lithium manganese oxide is about 1.5%. Among them, magnesium oxide, zirconium oxide and tungsten oxide account for about 25% of the mass fraction of the crystalline surface layer, and the rest is mainly about 75% of crystalline phosphorus oxide and trace residual lithium absorbed by low-nickel-nickel-cobalt lithium manganate.

[0064] The method used refers to Example 1, the difference is that the heat treatment and tempering are in air atmosphere, the heat treatment is sintering at 700° C. for 8 hours, and the tempering treatment is at 500...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com