A method of chemical vapor deposition coated carbon and the prepared coated high-voltage ternary material

A technology of chemical vapor deposition and ternary materials, which is applied in the field of cathode materials for lithium-ion secondary batteries, can solve the problems of easy aggregation of carbon source precursors, uneven coating of roasted products, and influence on the performance of cathode materials, so as to achieve a uniform improvement properties and compactness, reducing residual lithium content, and improving processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

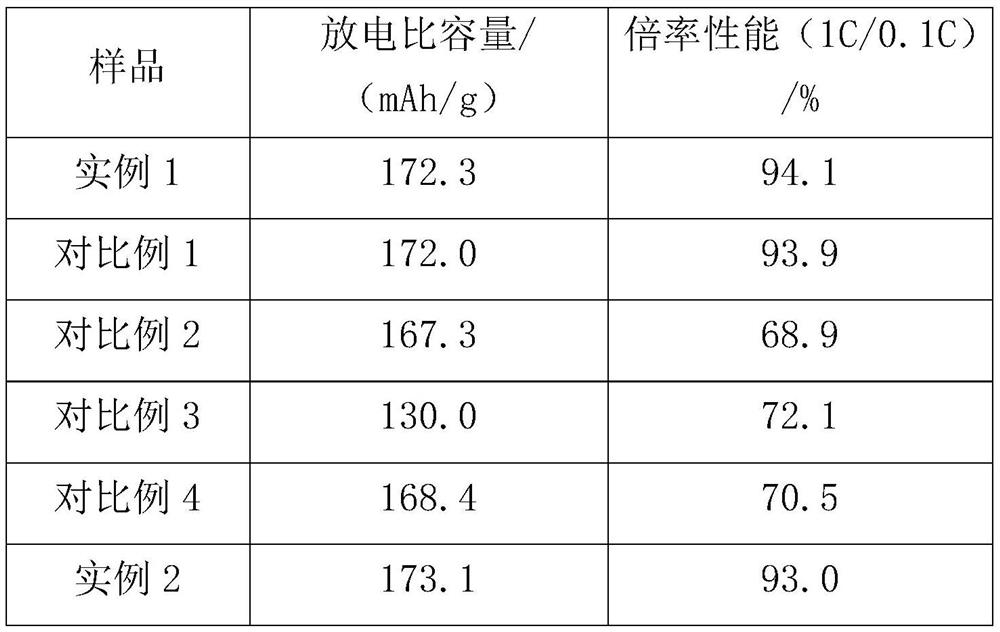

Embodiment 1

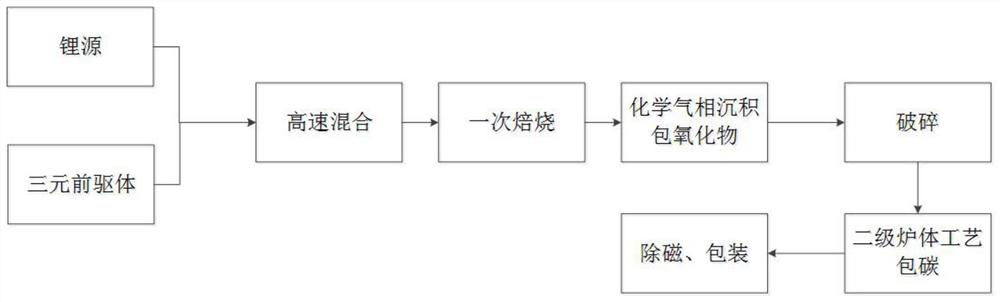

[0035] A method for preparing a gas-phase coated high-voltage ternary material, comprising the steps of:

[0036] 1) According to the molecular formula Li 1.03 Ni 0.5 co 0.2 mn 0.3 o 2 , weigh lithium carbonate, Ni 0.5 co 0.2 mn 0.3 (OH) 2 The precursor is added to a high-speed mixer and mixed evenly to obtain a mixture I;

[0037] 2) Put the mixture I into a vapor deposition furnace for high-temperature calcination, the rotation speed of the furnace body is 1 revolution / min, the calcination temperature is 880° C., the calcination time is 12 hours, and the calcination atmosphere is oxygen to obtain the ternary material II;

[0038] 3) Put tetrabutyl titanate into a glass container and heat at a temperature of 300°C, and bring the volatilized tetrabutyl titanate into the above-mentioned vapor deposition furnace through flowing nitrogen gas for chemical deposition at a deposition temperature of 600°C. The deposition time is 6 hours, and the vapor-coated ternary material...

Embodiment 2

[0052] A method for preparing a chemical vapor deposition method to coat a high-voltage ternary material, comprising the following steps:

[0053] 1) According to the molecular formula Li 1.05 Ni 0.5 co 0.2 mn 0.3 o 2 , weigh lithium source, Ni 0.5 co 0.2 mn 0.3 (OH) 2 The precursor is added to a high-speed mixer and mixed evenly to obtain a mixture I;

[0054] 2) Put the mixture I into a vapor deposition furnace for high-temperature calcination, the rotation speed of the furnace body is 3 revolutions per minute, the calcination temperature is 960° C., the calcination time is 8 hours, and the calcination atmosphere is oxygen to obtain the ternary material II;

[0055] 3) Put titanium tetrachloride into a glass container and heat at a heating temperature of 350°C, and bring the volatilized titanium tetrachloride into the above-mentioned vapor deposition furnace through flowing argon gas for chemical deposition at a deposition temperature of 700°C. The deposition time i...

Embodiment 3

[0065] A method for preparing a chemical vapor deposition method to coat a high-voltage ternary material, comprising the following steps:

[0066] 1) According to the molecular formula Li 1.05 Ni 0.6 co 0.2 mn 0.2 o 2 , weigh lithium source, Ni 0.6 co 0.2 mn 0.2 (OH) 2 The precursor is added to a high-speed mixer and mixed evenly to obtain a mixture I;

[0067] 2) Put the mixture I into a vapor deposition furnace for high-temperature calcination, the rotation speed of the furnace body is 3 revolutions per minute, the calcination temperature is 880°C, the calcination time is 8h, and the calcination atmosphere is oxygen to obtain the ternary material II;

[0068] 3) Put titanium tetrachloride into a glass container and heat at a heating temperature of 350°C, and bring the volatilized titanium tetrachloride into the above-mentioned vapor deposition furnace through flowing helium gas for chemical deposition at a deposition temperature of 700°C. The deposition time is 4h, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com