Method for reducing grain boundary impedance and interface impedance of oxide electrolyte

An interface impedance and electrolyte technology, applied in electrolytes, circuits, electrical components, etc., can solve the problems of high electrode/electrolyte interface impedance, poor contact of oxide solid electrolyte high temperature sintered electrodes, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

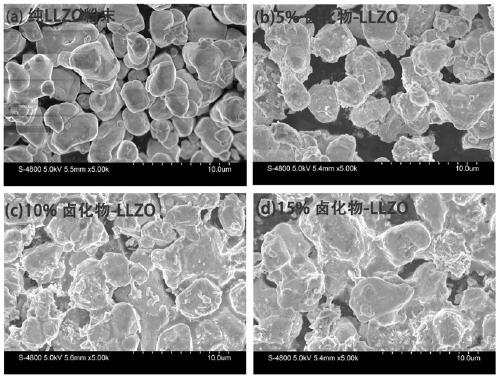

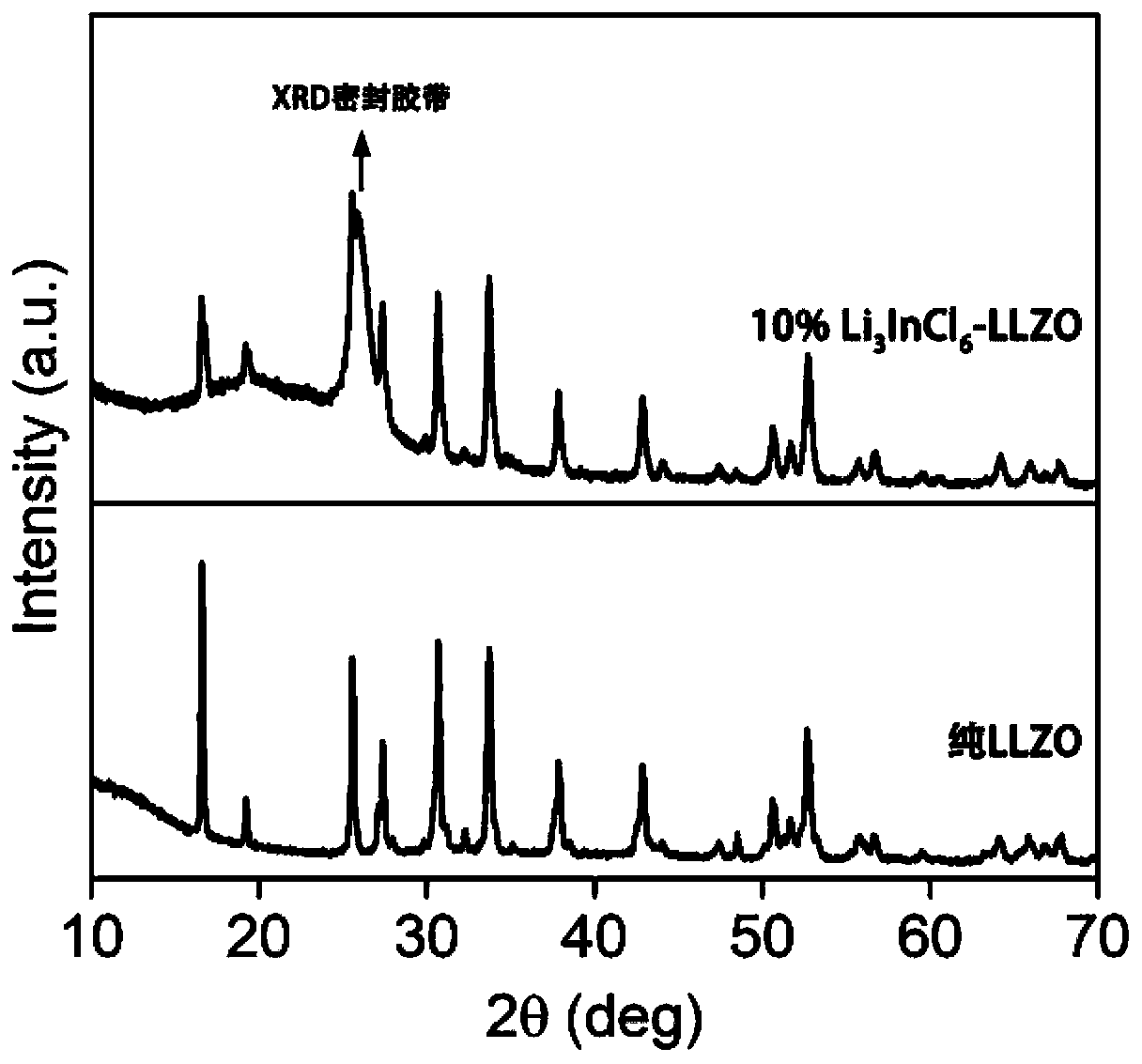

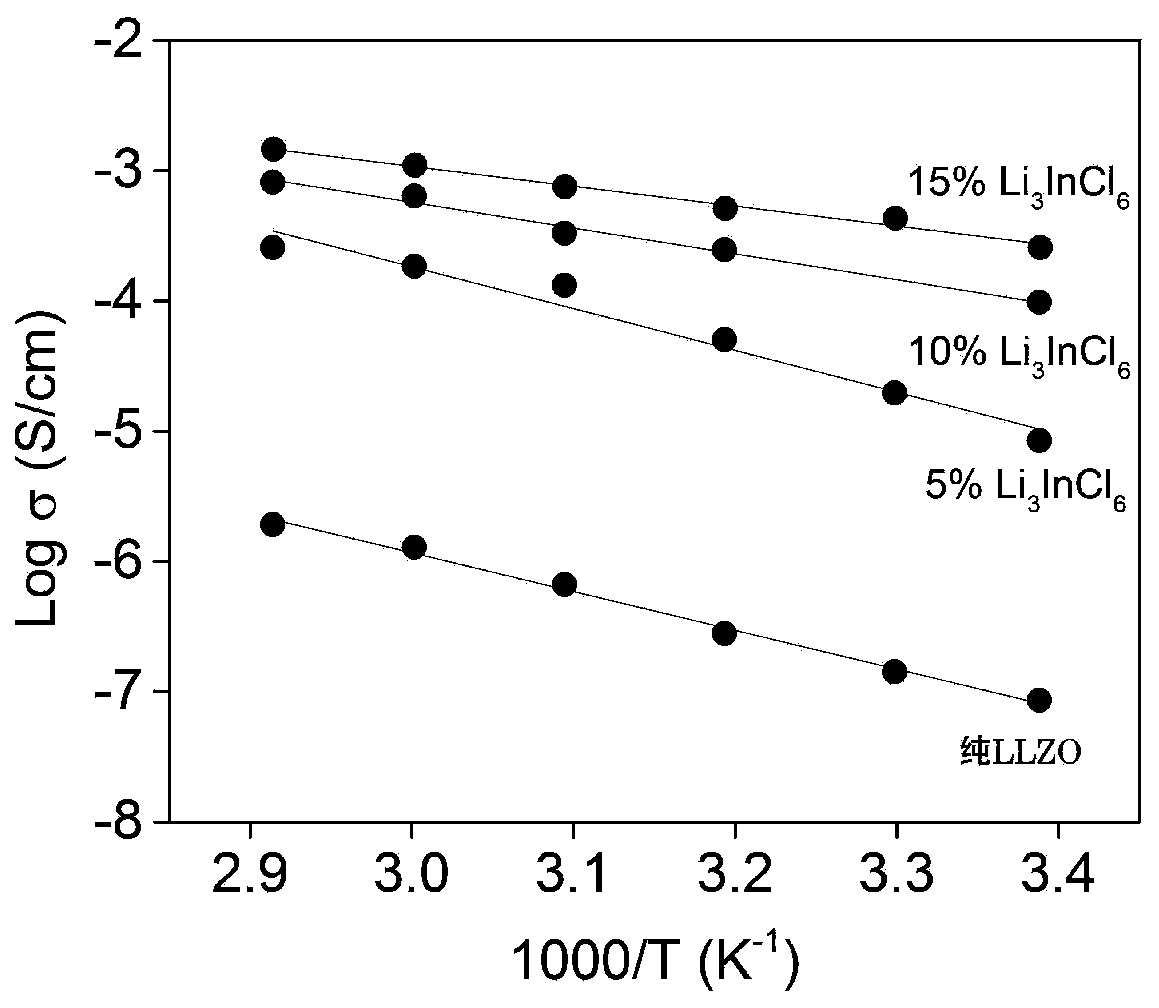

[0051] Example 1 Composite 5% Li 3 InCl 6 -LLZO solid electrolyte powder / sheet

[0052] This embodiment provides a composite 5% Li 3 InCl 6 -Preparation of LLZO solid electrolyte powder / sheet, the steps are as follows:

[0053] (1) 52.6mg of Li 3 InCl 6 Dissolve in 5mL of ethanol:water mixed solution with a volume ratio of 1:3; take 1000mg of garnet-type solid electrolyte LLZO particles and mix in the solution;

[0054] (2) Place the mixed solution in a vacuum oven, and remove the solvent by vacuuming at room temperature; set the oven to 80°C for 12h; then set the temperature to 200°C for 5h to obtain a composite 5% Li 3 InCl 6 -LLZO solid electrolyte powder.

[0055] (3) the composite Li obtained above 3 InCl 6 -The LLZO solid electrolyte powder is transferred to an argon-protected glove box, and pressed into a battery mold with a pressure of 370MPa to obtain the composite 5% Li obtained above. 3 InCl 6 - LLZO solid electrolyte sheet.

Embodiment 2

[0056] Example 2 Composite 10% Li 3 InCl 6 -LLZO solid electrolyte powder / sheet

[0057] This embodiment provides a composite 5% Li 3 InCl 6 -Preparation of LLZO solid electrolyte powder / sheet, the steps are as follows:

[0058] (1) 111.1 mg of Li 3 InCl 6 Dissolve in 5mL of ethanol with a volume ratio of 1:3: water mixed solution; take commercially available garnet-type solid electrolyte LLZO particles 1000mg and mix with the solution;

[0059] (2) Place the mixed solution in a vacuum oven, and remove the solvent by vacuuming at room temperature; then set the oven to 80°C for 12h, and then set the temperature to 200°C for 5h to obtain a composite 10% Li 3 InCl 6 - LLZO solid electrolyte powder;

[0060] (3) adopt the compression molding method of embodiment 1, obtain composite 10% Li 3 InCl 6 - LLZO solid electrolyte sheet.

Embodiment 3

[0061] Example 3 Composite 15% Li 3 InCl 6 -LLZO solid electrolyte powder / sheet

[0062] This embodiment provides a composite 5% Li 3 InCl 6 -Preparation of LLZO solid electrolyte powder / sheet, the steps are as follows:

[0063] (1) 176.5mg of Li 3 InCl 6 Dissolve in 5mL of ethanol with a volume ratio of 1:3: water mixed solution; take commercially available garnet-type solid electrolyte LLZO particles 1000mg and mix with the solution;

[0064] (2) Place the mixed solution in a vacuum oven, and remove the solvent by vacuuming at room temperature; then set the oven to 80°C for 12h; then set the temperature to 200°C for 5h to obtain a composite 15% Li 3 InCl 6 -LLZO solid electrolyte powder.

[0065] (3) adopt the compression molding method of embodiment 1, obtain composite 15% Li 3 InCl 6 - LLZO solid electrolyte sheet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com