Compensation for substrate doping for in-situ electromagnetic inductive monitoring

An electromagnetic induction and substrate technology, applied in the direction of using electromagnetic means, using electrical devices, grinding machine parts, etc., can solve problems such as non-uniformity, reduce non-uniformity, improve reliability, and avoid insufficient grinding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

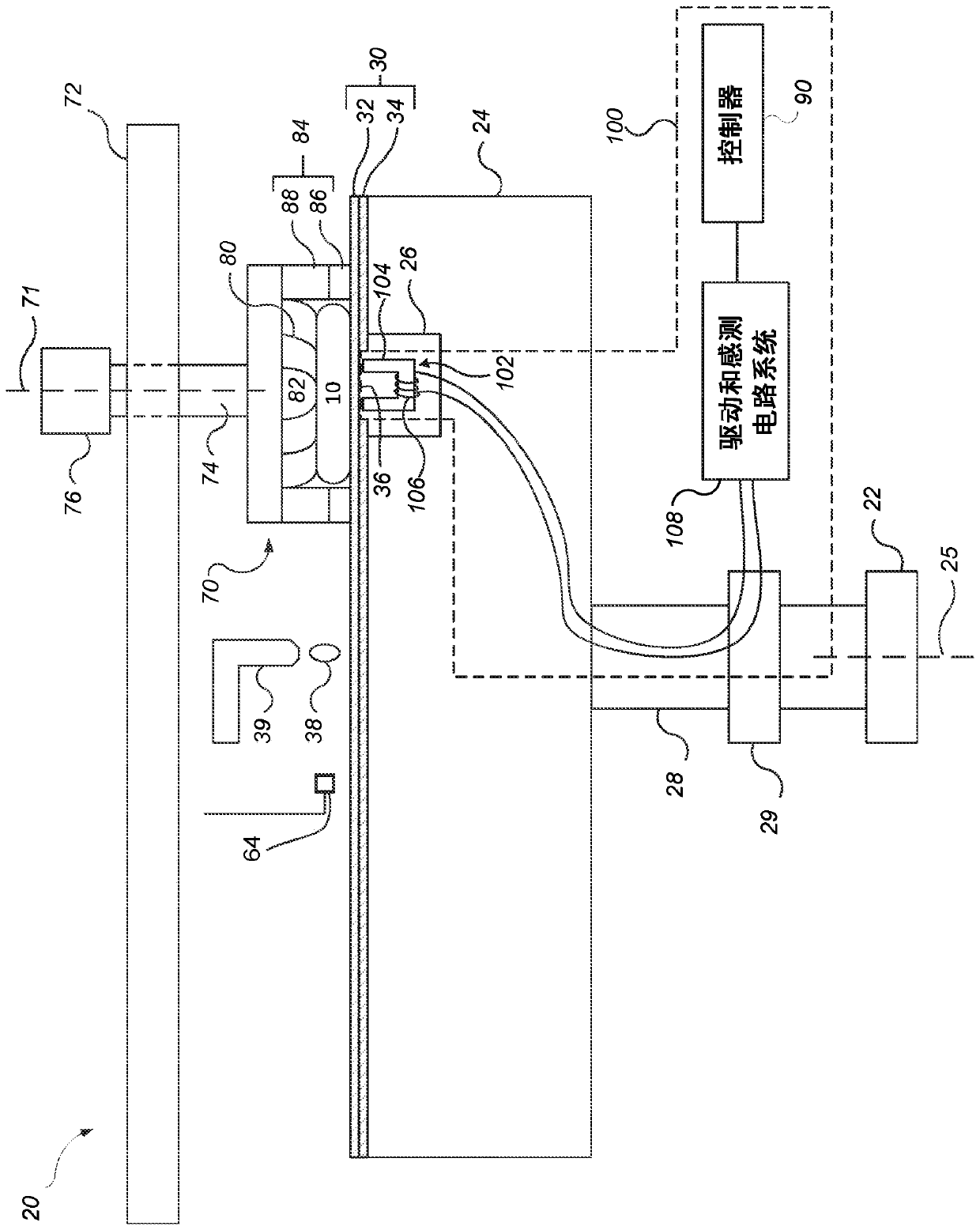

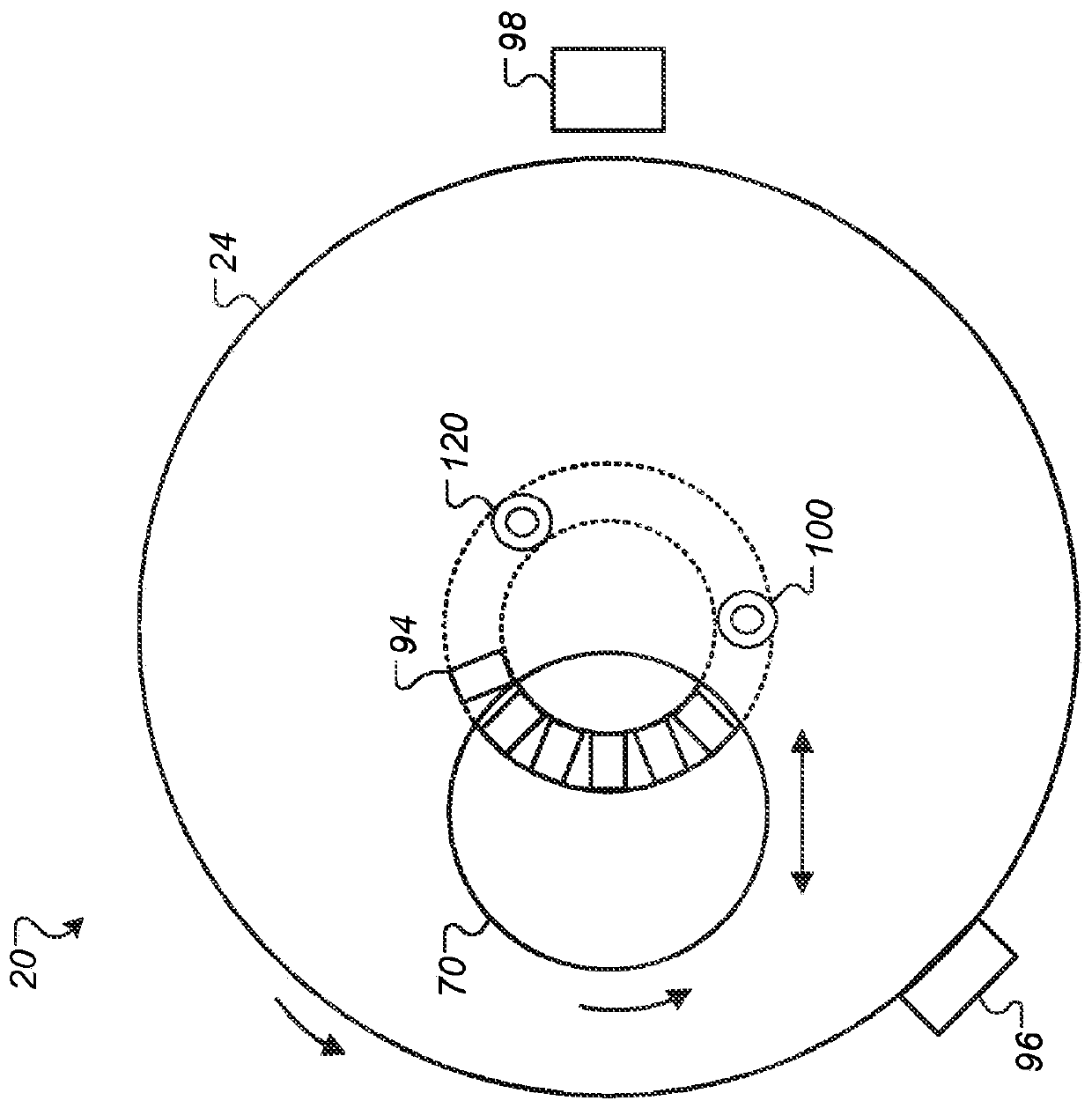

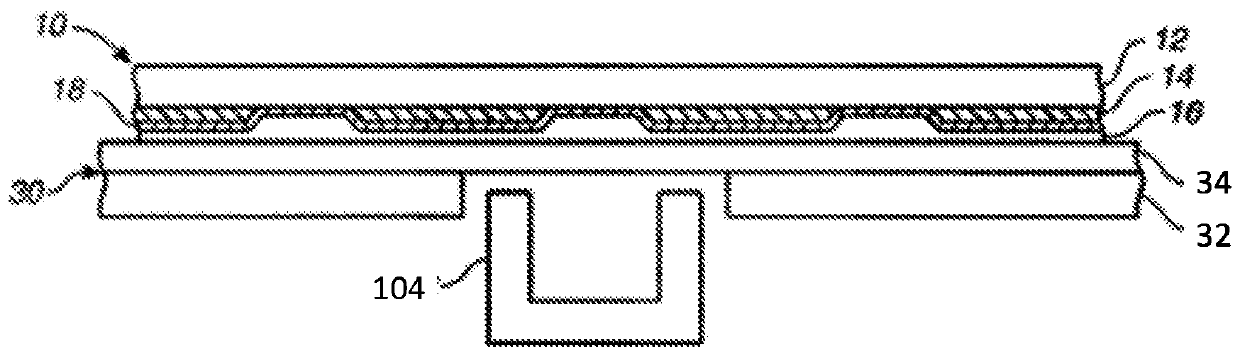

[0020] One monitoring technique for grinding operations is to induce eddy currents (eg, using an alternating current (AC) drive signal) in a conductive layer on the substrate. Induced eddy currents can be measured in situ by eddy current sensors during grinding to generate a signal. Assuming that the outermost layer undergoing grinding is the conductive layer, the signal from the sensor should depend on the thickness of the conductive layer. Based on the monitoring, control parameters of the milling operation (eg, milling rate) can be adjusted in situ. Additionally, the milling operation may be terminated based on an indication that the monitored thickness has reached a desired endpoint thickness.

[0021] In fact, the magnetic field generated by an eddy current sensor does not stop within the conductive layer, but can extend into the underlying substrate. Without being bound by any particular theory, the skin surface depth in these magnetically permeable materials for the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com