A hot push-bending forming method of a wind tunnel scimitar

A hot push and wind tunnel technology, applied in the direction of forming tools, testing of machine/structural components, instruments, etc., can solve the problems of difficulty in guaranteeing the accuracy of forming dimensions, large ingots and forming dies, and increased machining allowances, etc. Achieve the effect of satisfying mechanical properties, small tonnage of blanks, and stable forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

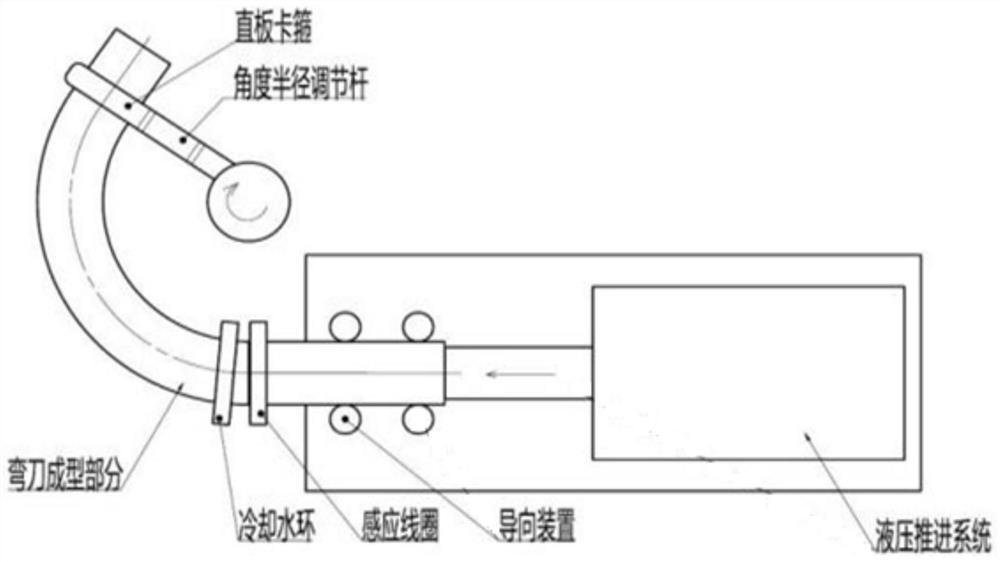

[0028] For the principle of this embodiment, see figure 1 , this embodiment includes the following steps:

[0029] a. Select a long steel plate made of S03 maraging stainless steel, and the size of the steel plate is 6000mm long, 650mm wide and 85mm thick;

[0030] b. Install a rectangular cooling water ring and a rectangular induction coil that match the section size of the steel plate on the pushing machine;

[0031] c. Pass the steel plate through the rectangular cooling water ring and the rectangular induction coil, one end is fixed on the rectangular push table of the hydraulic propulsion system of the pushing machine, and the other end is fixed on the rectangular clamp of the pushing machine, and the rectangular clamp is connected to the angle radius Adjusting lever;

[0032] d. The rectangular induction coil heats the part of the steel plate at a frequency of 800Hz to 1000Hz. When the local temperature of the steel plate at the position of the rectangular induction co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com