TPU film and preparation method thereof

A thin film and film layer technology, applied in chemical instruments and methods, lamination, coating, etc., can solve problems such as poor customer experience, limitations, and poor durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

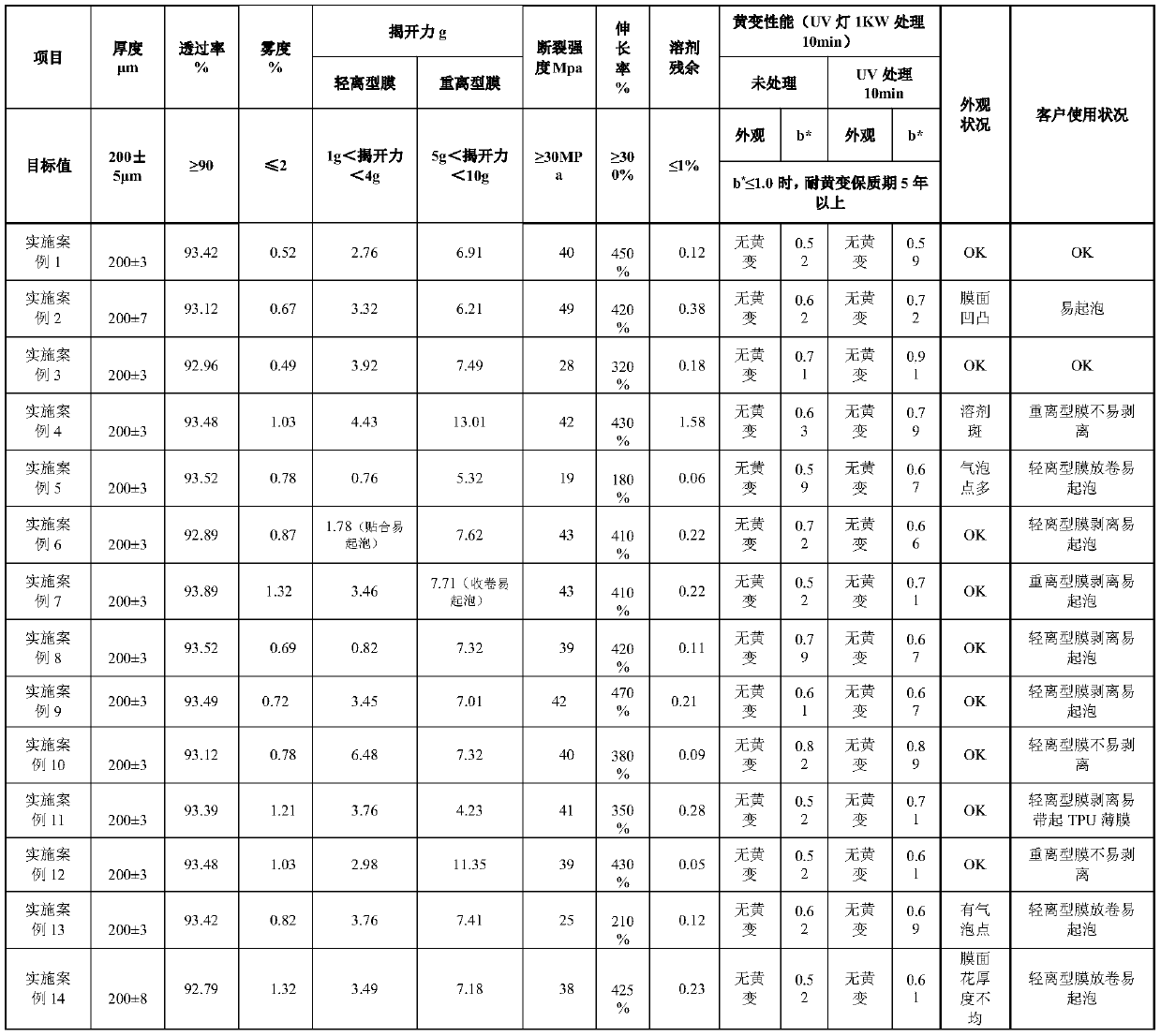

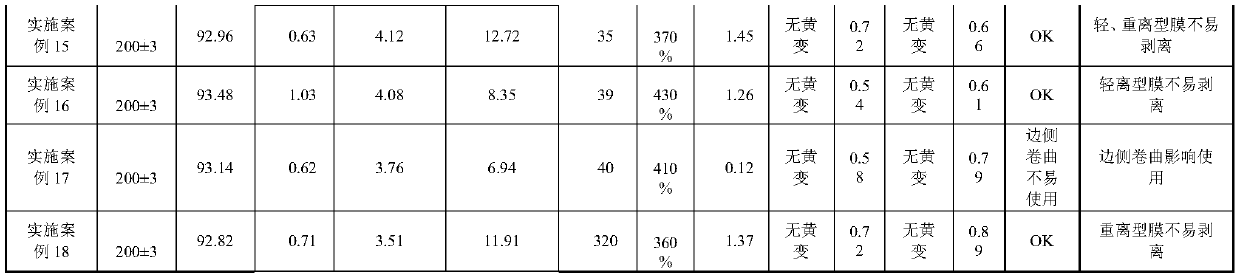

Examples

Embodiment example 1

[0020] Select solid content 50wt%, number average molecular weight 180000, viscosity 40000cps, aliphatic hydrocarbon polyurethane resin, its transmittance is more than 90%, use solvent MEK to dilute the viscosity of this TPU solution to within 20000cps, dilute the TPU solution after dilution with Coating on a 70μm PET heavy-release film with a release force of 600g at a speed of 5m / min, and then passing through temperatures of 50°C, 80°C, 130°C, 150°C, 140°C and wind frequencies of 400Hz, 600Hz, 1000Hz, 1500Hz , 1800Hz 5-section oven drying, and finally on-line lamination on a 40μm PET light release film with a release force of 350g to obtain a TPU film.

Embodiment 2

[0022] Different from Example 1, an aliphatic hydrocarbon polyurethane resin with a solid content of 50 wt%, a number average molecular weight of 210,000, and a viscosity of 40,000 cps was selected.

Embodiment 3

[0024] Different from Example 1, an aliphatic hydrocarbon polyurethane resin with a solid content of 50 wt%, a number average molecular weight of 130,000, and a viscosity of 40,000 cps was selected.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com