Composite carbon source for deep denitrification of leather wastewater and preparation method thereof

A technology for deep denitrification and compound carbon source, applied in chemical instruments and methods, animal processing wastewater treatment, special compound water treatment, etc. Different effects, etc., to achieve the effect of improving biochemical treatment effect, accelerating decomposition, and enhancing adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

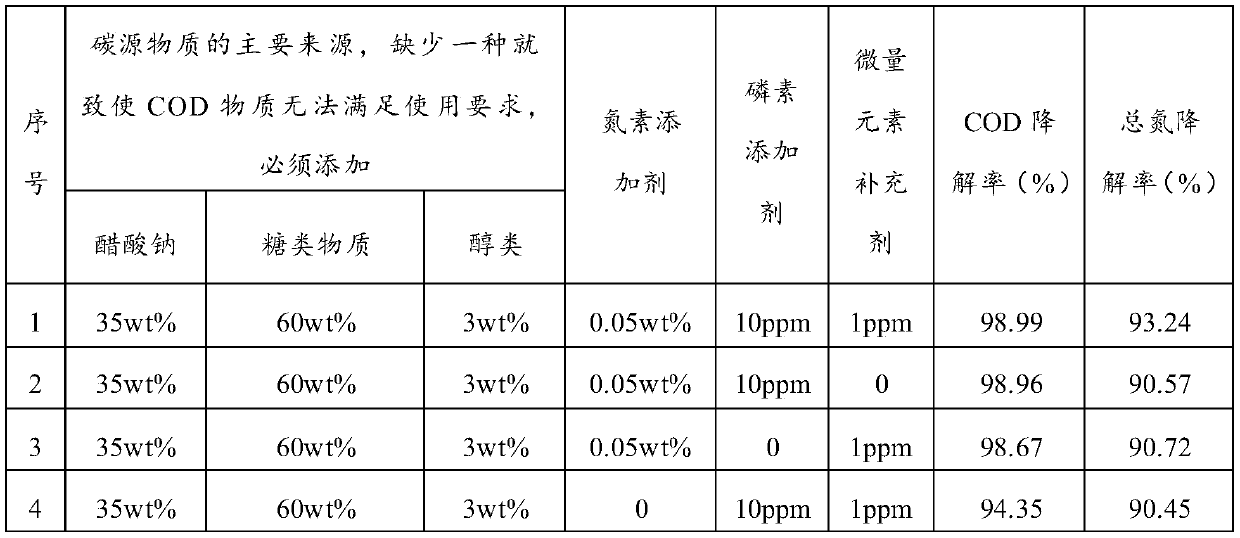

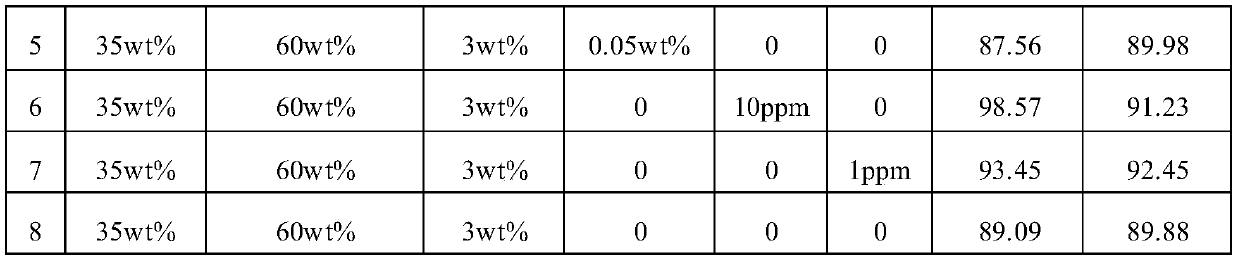

Examples

preparation example Construction

[0030] The application also provides a method for preparing a composite carbon source for deep denitrification of the leather wastewater, comprising the following steps:

[0031] Prepare sodium acetate solution according to mass percentage;

[0032] Dissolving sugars, alcohol compounds, nitrogen additives, phosphorus additives, and trace element supplements respectively according to the mass percentage content, and then sequentially mixing with sodium acetate solution to obtain a composite carbon source for deep denitrification of leather wastewater.

[0033] In the preparation process of the above-mentioned composite carbon source, the applicant first prepared a sodium acetate solution to ensure the amount of carbon source. In the present application, preferably adopt acetic acid and sodium carbonate to produce sodium acetate, promptly calculate the quality of required acetic acid and sodium carbonate according to the amount of sodium acetate, be respectively configured into ...

Embodiment 1

[0041] The preparation of a composite carbon source agent for deep denitrification of leather wastewater mainly includes the following steps:

[0042] Step 1: Preparation of 25% sodium acetate solution

[0043] 1) Preparation of 25% sodium carbonate solution: Weigh 63.3g of sodium carbonate, add 253mL of water, stir until completely dissolved, and obtain 25% sodium carbonate solution;

[0044] 2) Preparation of 48% acetic acid solution by volume: Weigh 91.5g (about 88mL) of acetic acid, add 95mL of water, and mix well to obtain the acetic acid solution;

[0045] 3) Add the acetic acid solution to the reactor, turn on the stirring device, set the rotation speed to 80r / min, slowly add the sodium carbonate solution to obtain the sodium acetate solution;

[0046] Step 2: Add carbohydrates

[0047] 1) Weigh 50g of starch, add to boiling water and stir until completely dissolved;

[0048] 2) Weigh 75g of industrial glucose, add it to the starch solution, and stir until completely...

Embodiment 2

[0060] The preparation of a composite carbon source agent for deep denitrification of leather wastewater mainly includes the following steps:

[0061] Step 1: Preparation of 30% sodium acetate solution.

[0062] 1) Preparation of 30% sodium carbonate solution: weigh 94.9g of sodium carbonate, add 271mL of water, stir until completely dissolved, and obtain 30% sodium carbonate solution;

[0063] 2) Preparation of 73% acetic acid solution by volume:

[0064] Weigh 137.2g (about 131mL) of acetic acid, add 48mL of water, and mix well to obtain the acetic acid solution;

[0065] 3) Add the acetic acid solution to the reactor, turn on the stirring device, set the rotation speed to 80r / min, slowly add the sodium carbonate solution to obtain the sodium acetate solution;

[0066] Step 2: Add carbohydrates

[0067] 1) Weigh 60g of starch, add to boiling water and stir until completely dissolved;

[0068] 2) Weigh 67.5g of industrial glucose, add it to the starch solution, and stir u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com