Biomass gasification wastewater treatment method and device

A treatment method and a treatment device technology, applied in the direction of oxidized water/sewage treatment, water/sewage treatment, anaerobic digestion treatment, etc., can solve the problems of weak impact load resistance and poor treatment effect, and achieve the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

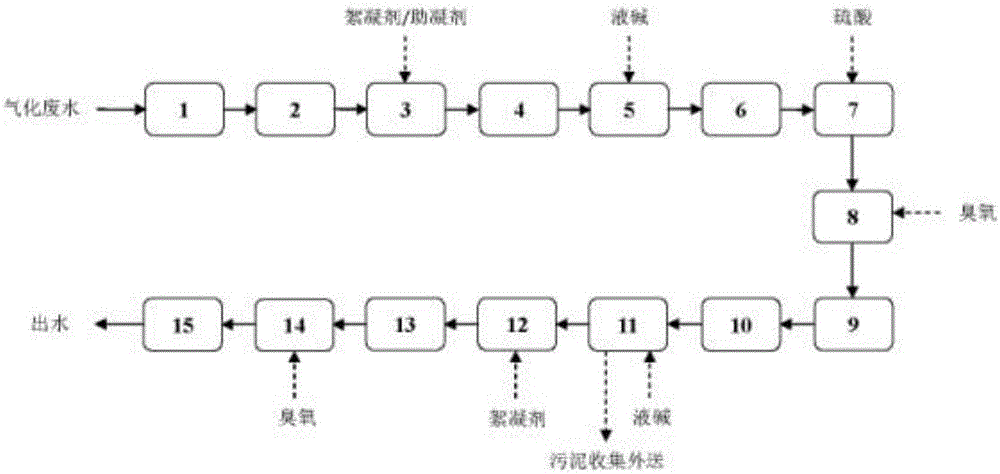

[0043] This embodiment provides a treatment method for biomass gasification wastewater. The processing method includes the following steps:

[0044] (1) Biomass gasification wastewater enters the oil separation device for oil separation treatment to remove floating oil and most of the suspended matter; then enters the first coagulation device and air flotation device to remove emulsified oil and suspended matter; then Enter the first ozone oxidation treatment device with an ozone dosage of 5mg / L for the first ozone oxidation treatment to remove residual polycyclic aromatic hydrocarbons and cyanide in the wastewater, reduce its toxicity to the subsequent biochemical treatment process, and ensure The subsequent biochemical treatment device runs stably, and finally collects the first effluent after pretreatment. Among them, the biomass gasification wastewater is a biomass gasification wastewater from a factory, with a COD of 1800mg / L, a BOD of 400mg / L, ammonia nitrogen (calculate...

Embodiment 2

[0049] This embodiment provides a treatment method for biomass gasification wastewater. The processing method includes the following steps:

[0050] (1) Biomass gasification wastewater enters the oil separation device for oil separation treatment to remove floating oil and most of the suspended matter; then enters the first coagulation device and air flotation device to remove emulsified oil and suspended matter; then Enter the first ozone oxidation treatment device with an ozone dosage of 5mg / L for the first ozone oxidation treatment to remove residual polycyclic aromatic hydrocarbons and cyanide in the wastewater, reduce its toxicity to the subsequent biochemical treatment process, and ensure The subsequent biochemical treatment device runs stably, and finally collects the first effluent after pretreatment. Among them, the biomass gasification wastewater is a biomass gasification wastewater from a factory, with a COD of 500mg / L, a BOD of 200mg / L, ammonia nitrogen (calculated...

Embodiment 3

[0055] This embodiment provides a treatment method for biomass gasification wastewater. The processing method includes the following steps:

[0056] (1) Biomass gasification wastewater enters the adjustment tank for homogeneous and even volume adjustment; then enters the oil separation device for oil separation treatment to remove floating oil and most of the suspended matter; then enters the first coagulation device and gas In the floating device, emulsified oil and suspended matter are removed; then enter the pH adjustment device, adjust the pH to 10 by adding sodium hydroxide to it, and then enter the ammonia nitrogen stripping device to remove ammonia nitrogen; finally enter the ozone dosage is 4mg / L of the first ozone oxidation treatment device to carry out the first ozone oxidation treatment to remove the residual polycyclic aromatic hydrocarbons and cyanide in the wastewater, reduce its toxicity to the subsequent biochemical treatment process, and ensure the stable ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com