Distiller's yeast and preparation method and application method thereof

A technology for koji and koji blanks, which is applied to the field of koji and its preparation, can solve the problems of poor wine quality and flavor, low survival rate of beneficial bacteria, and poor controllability of culturing bacteria, so as to avoid contamination of miscellaneous bacteria and improve survivability. , the effect of stabilizing quality and flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

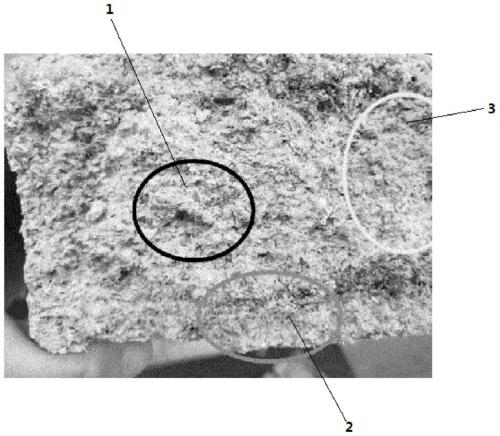

Image

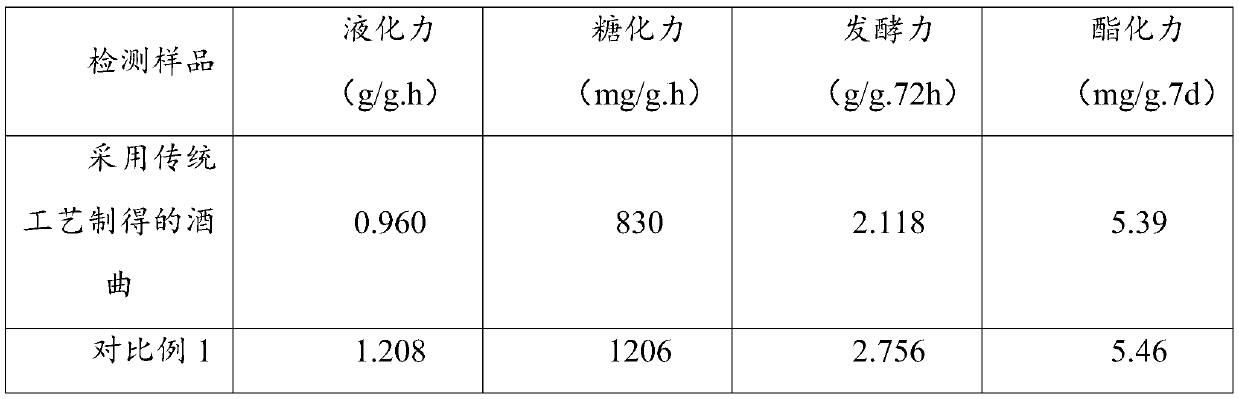

Examples

preparation example Construction

[0014] The embodiment of the present invention provides a kind of preparation method of distiller's yeast, comprises the steps:

[0015] Step 101, inoculate the koji strains obtained through selenium-enriched culture into the crushed koji-making raw materials, mix the ingredients to obtain a mixed material, and then make the mixed material into a koji base.

[0016] Step 102, put the koji blank into a pre-sterilized koji training room, control the temperature, humidity and oxygen supply of the koji training room in stages, and carry out the cultivation of the koji blank.

[0017] Step 103, when it is detected that the temperature, humidity and water content of the koji meet the requirements for maturation of the koji, the koji can be produced to obtain the koji.

[0018] Preferably, the koji species include Aspergillus niger, Monascus, Saccharomyces cerevisiae, Pichia pastoris, caproic acid bacteria and lactic acid bacteria obtained through selenium-enriched culture.

[0019]...

Embodiment 1

[0062] The distiller's yeast of embodiment 1 is prepared by following steps:

[0063] The koji-making raw material is crushed and passed through a 40-mesh sieve to obtain a broken koji-making raw material with a crushing strength of 35.6%. Inoculate the Aspergillus niger (the inoculation amount is 0.3% of the weight of the raw material for koji making), the Monascus (the inoculation amount is 0.02% of the weight of the raw material for koji making) obtained by the cultivation of the selenium-enriched medium, and Saccharomyces cerevisiae respectively in the broken koji-making raw material. (the inoculation amount is 0.06% of the koji-making raw material weight), Pichia pastoris (the inoculum amount is 0.004% of the koji-making raw material weight), caproic acid bacteria (the inoculum amount is 0.03% of the koji-making raw material weight) and lactic acid bacteria (the inoculum amount is 0.03% of the koji-making raw material weight) 0.002% of the koji-making raw material weight)...

Embodiment 2

[0065] Compared with Example 1, its difference is only: inoculate respectively the Aspergillus niger (inoculum size is 0.45% of the raw material weight for making koji), Monascus ( The inoculation amount is 0.05% of the koji-making raw material weight), Saccharomyces cerevisiae (the inoculation amount is 0.09% of the koji-making raw material weight), Pichia pastoris (the inoculum amount is 0.01% of the koji-making raw material weight), caproic acid bacteria (the inoculation amount is 0.01% of the koji-making raw material weight), 0.01% of the koji-making raw material weight) and lactic acid bacteria (the inoculum size is 0.004% of the koji-making raw material weight), carry out the mixing of ingredients, obtain the mixed material. All the other conditions are the same as in Example 1 to obtain distiller's yeast.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com