Production process of ultra-soft bicomponent skin-core structure superfine fiber and superfine fiber of production process

A technology of ultra-fine fiber and skin-core structure, which is applied in fiber treatment, fiber chemical characteristics, and adding pigments to spinning solution, etc. It can solve the problem of unsatisfactory mechanical properties, water absorption performance and poor flexibility of circular skin-core structure fibers, etc. problems, to achieve the effect of improving flexibility and mechanical properties, increasing tension, and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is further illustrated by the following examples.

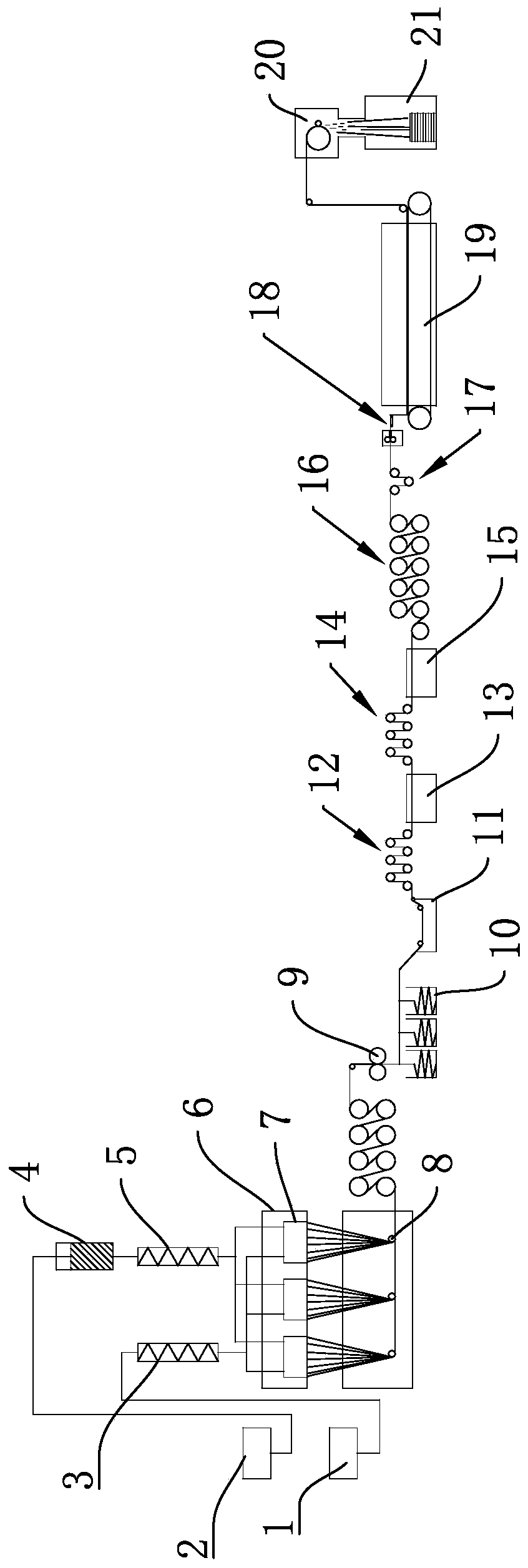

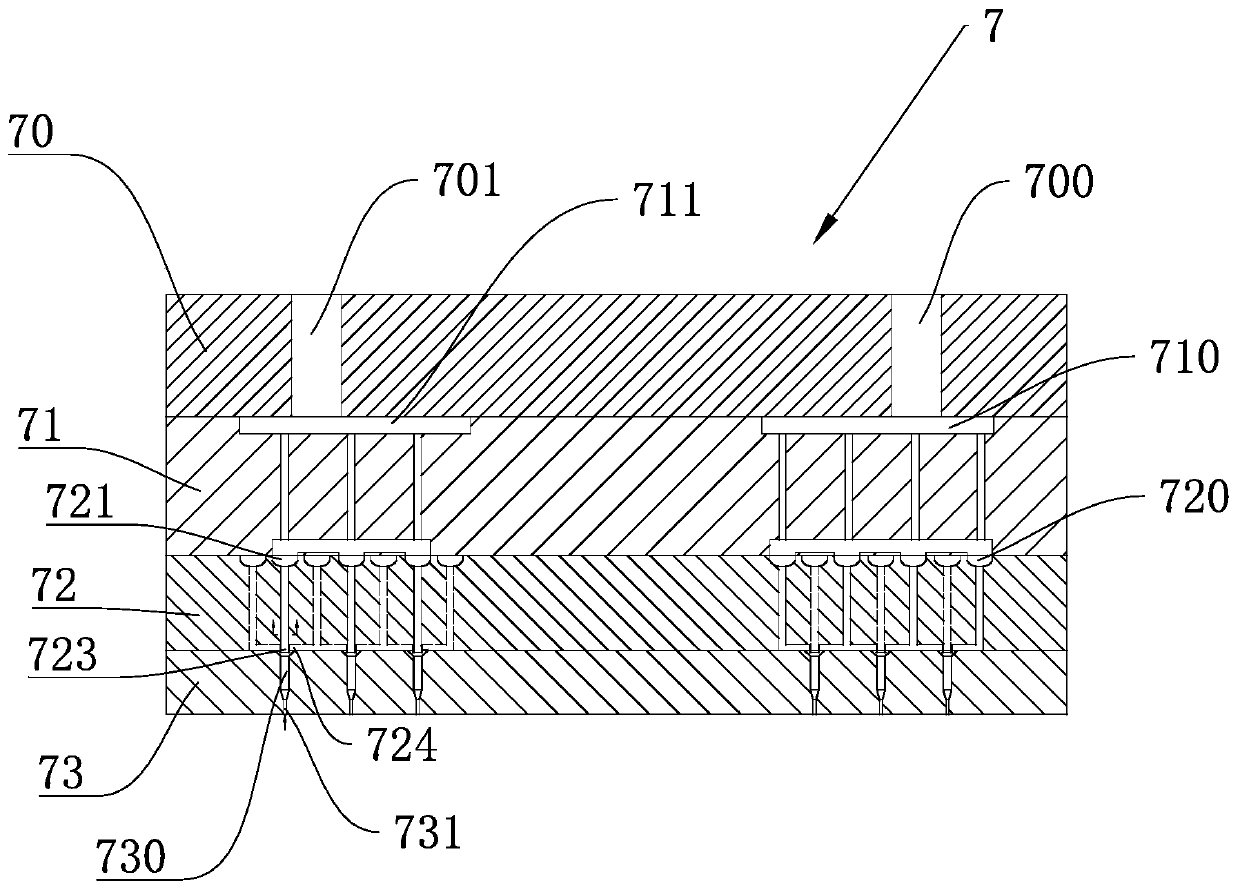

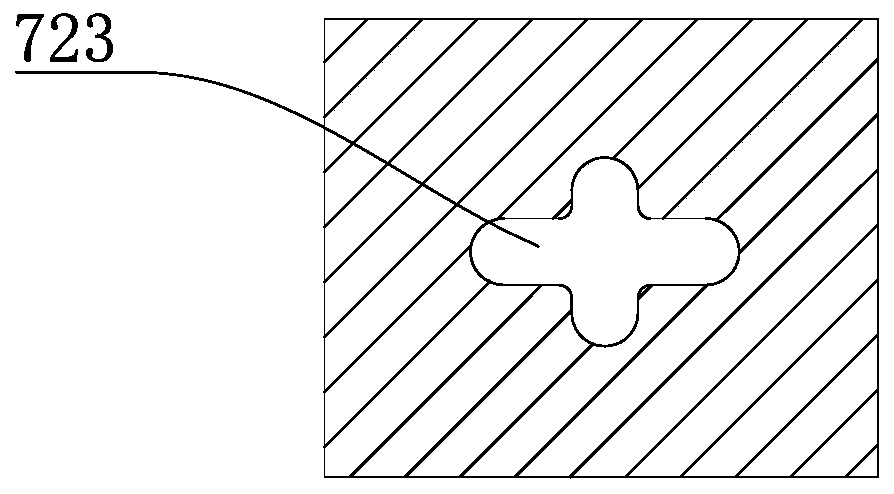

[0029] Such as figure 1 As shown, a super-soft two-component skin-core structure ultrafine fiber production process includes the following steps:

[0030] 1) The A component material is composed of PE chips, color masterbatch and POE masterbatch. The amount of color masterbatch is 0.5% to 1% of the mass of PE chip, and the mass of POE masterbatch is 3% to 15 of the mass of PE chip. %. The A component material is extruded from the A material barrel 1 through the A material screw extruder 3 and then enters the skin spinning channel of the composite spinning box 6.

[0031] 2) The B component material is composed of PET chips and antioxidant masterbatch, wherein the amount of antioxidant masterbatch is 0.1% to 0.5% of the mass of the PET chip. The B component material enters the B material screw extruder 5 from the B material barrel 2 through the drying tower 4, and the B material screw extruder 5 enters ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com