On-line monitoring device for simulated wire icing based on the law of icing in micro-topographic and micro-meteorological regions

A monitoring device and micro-meteorological technology, which is applied in the direction of measuring devices, cable installation, overhead installation, etc., can solve the problems of failure to achieve the expected effect, excessive temperature drift, and unsatisfactory, so as to enhance the actual application ability and avoid error amplification , Realize the effect of online monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

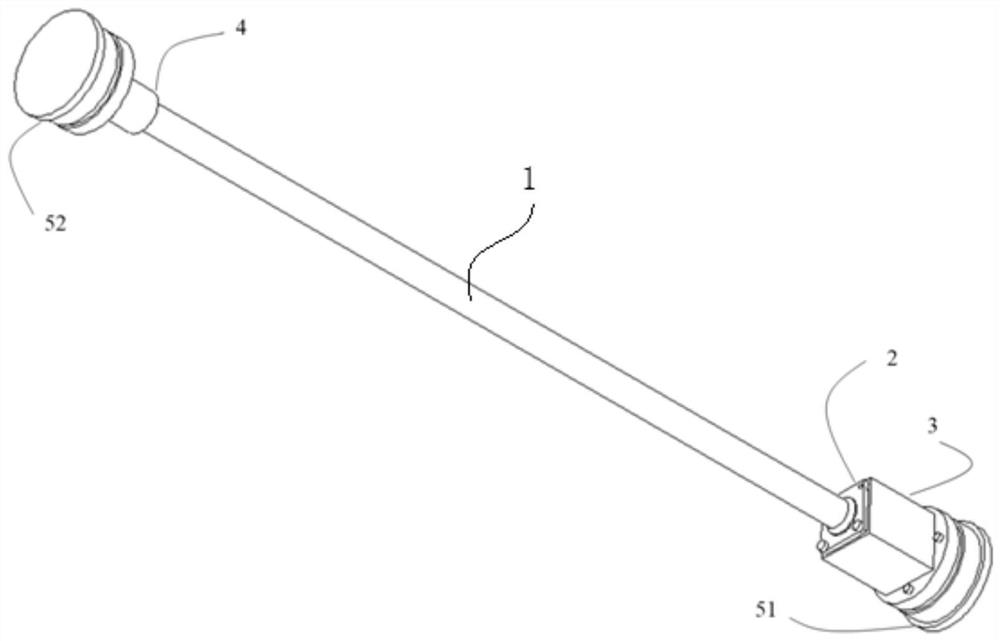

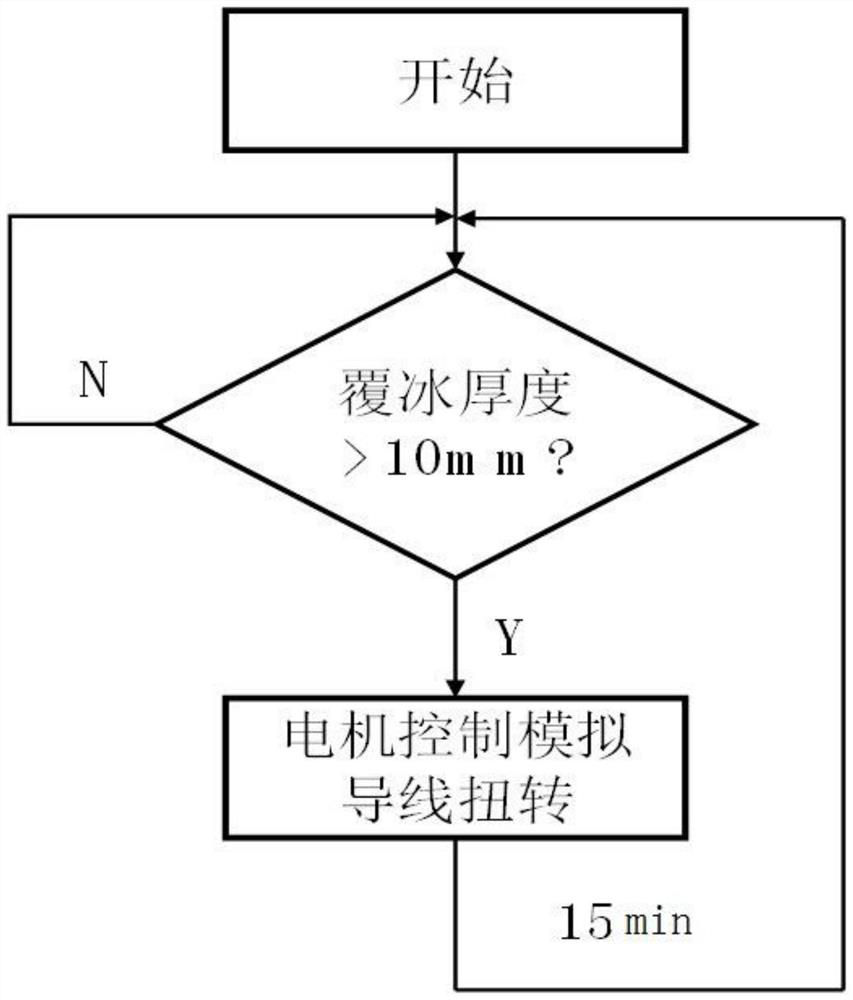

[0057] see Figure 1 to Figure 3 , an on-line monitoring device for icing on simulated wires based on the icing law in micro-topographic and micro-meteorological regions, mainly including simulated wires 1, stepping motor 2, motor fixing sleeve 3, rolling belt shaft bearing 4, sealing box I, sealing box II, Three-dimensional force sensor I51, stepper motor driver, three-dimensional force sensor II52, bracket, power supply, microcontroller I, microcontroller II, temperature sensor I, temperature sensor II, heating module I and heating module II.

[0058] One end of the analog wire 1 is connected to the transmission shaft 1 of the stepping motor 2, and the other end is connected to the head end of the rolling belt shaft bearing 4.

[0059] The simulated wire 1 is parallel to the monitored transmission line. The type and material of the simulated wire 1 are the same as those of the power transmission wire.

[0060] Analog wire 1 is a steel-cored aluminum stranded wire with the ...

Embodiment 2

[0103] The online monitoring device for icing on simulated conductors based on the law of icing in micro-topography and micro-meteorological areas mainly includes simulated conductors 1, stepper motor 2, motor fixed bushing 3, rolling belt shaft bearing 4, sealed box I, sealed box II, three-dimensional Force sensor I51, three-dimensional force sensor II52, stepper motor driver, bracket, power supply, microcontroller I, microcontroller II, temperature sensor I, temperature sensor II, heating module I and heating module II.

[0104] One end of the analog wire 1 is connected to the transmission shaft 1 of the stepping motor 2, and the other end is connected to the head end of the rolling belt shaft bearing 4.

[0105] The end of the transmission shaft II of the stepping motor 2 is covered with a motor fixing sleeve 3 .

[0106] Said motor fixing sleeve 3 outer cover is provided with sealing box 1.

[0107] A three-dimensional force sensor 151, a stepping motor driver and a micro...

Embodiment 3

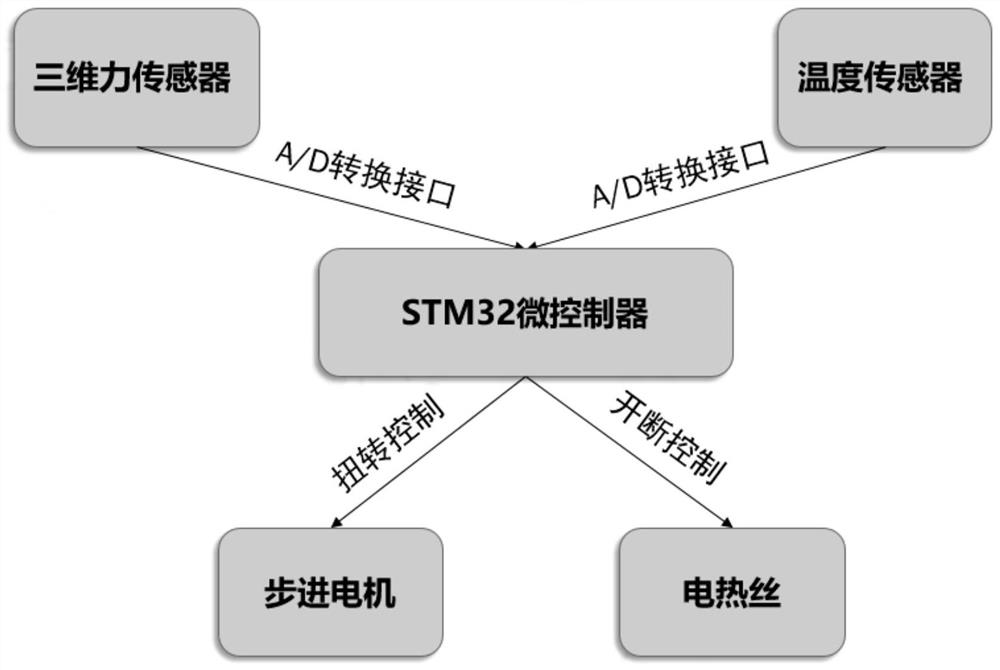

[0119] Based on the simulated wire icing on-line monitoring device for icing laws in micro-topographic and micro-meteorological regions, the main structure is shown in Embodiment 2, wherein the monitoring device also includes a microcontroller II, a temperature sensor I, a temperature sensor II, a heating module I and a heating module II.

[0120] The temperature sensor 1 and the heating module 1 are packaged in the sealed box 1.

[0121] Described temperature sensor 1 monitors the temperature t of sealed box 1 1 , and sent to the microcontroller I.

[0122] Described heating module 1 is connected with the I / O interface signal line of microcontroller 1.

[0123] When the microcontroller I receives the temperature t 1 min At this time, the microcontroller 1 communicates with the heating module 1 to provide a pulse signal for the heating module 1 to control the heating of the heating module 1.

[0124] When the microcontroller I receives the temperature t 1 >T max , microc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com