Preparation method of high-corrosion-resistance coating on surface of flexibly bonded neodymium iron boron-nickel zinc ferrite composite magnet

A technology of nickel-zinc ferrite and composite magnets, which is applied in the manufacture of permanent magnets, magnetic objects, inductors/transformers/magnets, etc., can solve the problems of high porosity, pulverization, and low mechanical properties of magnets, and achieve good durability Effect of high temperature and corrosion resistance, good magnetic and mechanical properties, long-term corrosion protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

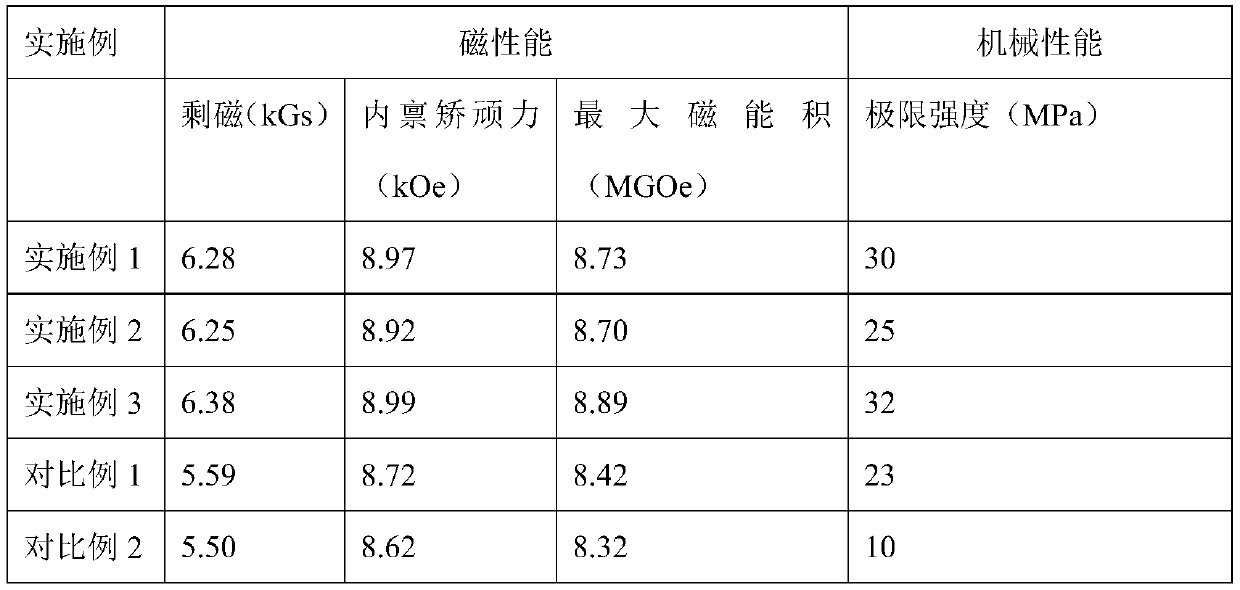

Embodiment 1

[0028] 1) Particle size recombination: use sieves with different mesh sizes to select the rapidly quenched NdFeB magnetic powder, separate the rapidly quenched NdFeB magnetic powder particles with different particle sizes, and mix according to the following mass percentage: the particle size is ≤200 mesh rapid quenched NdFeB magnetic powder Iron-boron magnetic powder is 5wt%, 100≤particle size<200 mesh quick-quenched NdFeB magnetic powder is 35wt%, 70≤particle size<100 mesh quick-quenched NdFeB magnetic powder is 60wt%; The sum of the percentages is 100%, and the rapidly quenched NdFeB magnetic powders of various particle sizes are mixed to obtain the rapidly quenched NdFeB magnetic powders with recombined particle sizes;

[0029] 2) Flexible bonded NdFeB-NiZn ferrite composite magnet: the rapid quenching NdFeB magnetic powder, 8wt% NiZn ferrite powder and 2wt% of the particle size recombined in the step 1) with a mass percentage of 90wt% % phenol formaldehyde type epoxy resin...

Embodiment 2

[0033] 1) Particle size recombination: use sieves with different mesh sizes to select the rapidly quenched NdFeB magnetic powder, separate the rapidly quenched NdFeB magnetic powder particles with different particle sizes, and mix according to the following mass percentage: the particle size is ≤200 mesh rapid quenched NdFeB magnetic powder The iron-boron magnetic powder is 10wt%, the 100≤particle size<200 mesh quick-quenched NdFeB magnetic powder is 35wt%, and the 70≤particle size<100 mesh quick-quenched NdFeB magnetic powder is 55wt%; The sum of the percentages is 100%, and the rapidly quenched NdFeB magnetic powders of various particle sizes are mixed to obtain the rapidly quenched NdFeB magnetic powders with recombined particle sizes;

[0034] 2) Flexible bonded NdFeB-NiZn ferrite composite magnet: the rapid quenching NdFeB magnetic powder, 10wt% NiZn ferrite powder and 10wt% recombined NdFeB magnetic powder with a mass percentage of 80wt% in step 1) % Double-part A-type e...

Embodiment 3

[0037] 1) Particle size recombination: use sieves with different mesh sizes to select the rapidly quenched NdFeB magnetic powder, separate the rapidly quenched NdFeB magnetic powder particles with different particle sizes, and mix according to the following mass percentage: the particle size is ≤200 mesh rapid quenched NdFeB magnetic powder 15wt% for iron-boron magnetic powder, 20wt% for quick-quenched NdFeB magnetic powder for 100≤particle size<200 mesh, 65wt% for fast-quenched NdFeB magnetic powder for 70≤particle size<100 mesh; the mass of fast-quenched NdFeB magnetic powder for each particle size The sum of the percentages is 100%, and the rapidly quenched NdFeB magnetic powders of various particle sizes are mixed to obtain the rapidly quenched NdFeB magnetic powders with recombined particle sizes;

[0038] 2) Flexible bonded NdFeB-NiZn ferrite composite magnet: the rapid quenching NdFeB magnetic powder, 8wt% NiZn ferrite powder and 7wt% of the particle size reorganization ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com