Separator without separator substrate

The technology of a diaphragm and a porous diaphragm is applied in the field of diaphragms without a diaphragm base material, and can solve the problems of a diaphragm without a polyolefin base material, and the improvement of the strength of the diaphragm is not disclosed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

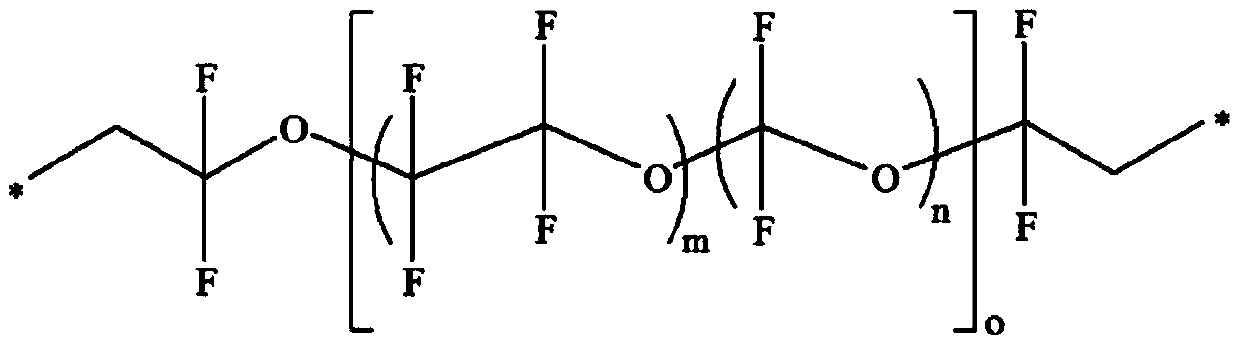

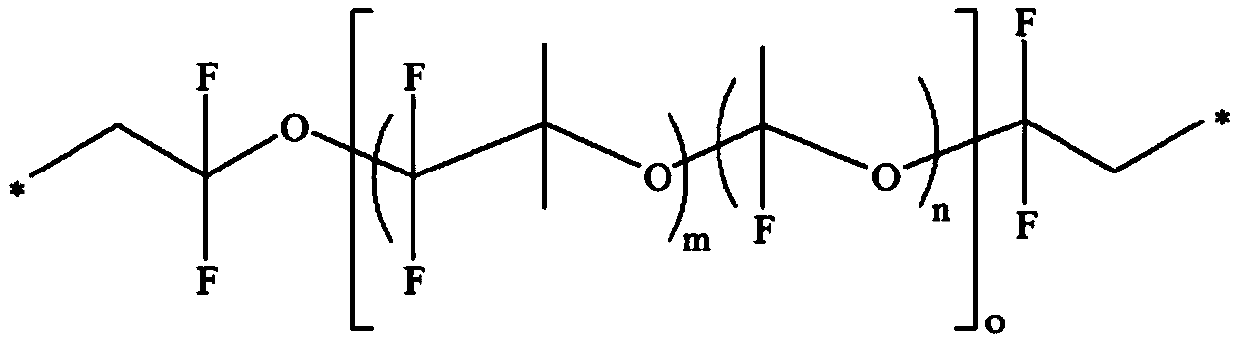

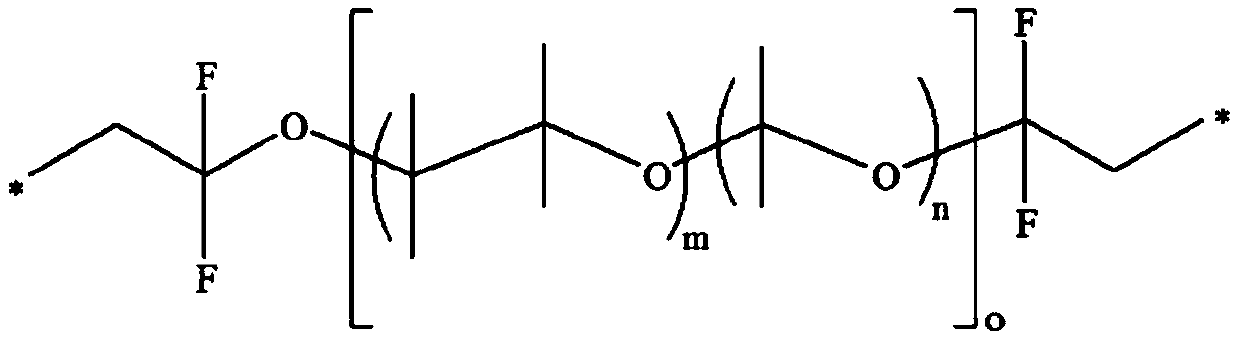

[0117] The slurry was made such that the content of solids comprising boehmite (AlO(OH)) as inorganic particles, Polyvinylidene fluoride-hexafluoropropylene copolymer (PVdF-HFP, 5130) and a compound represented by Chemical Formula 4 as a crosslinking agent.

[0118] Specifically, 28.08 g of boehmite (AlO(OH)), 7.2 g of PVdF-HFP, and 0.72 g of the compound represented by Chemical Formula 4 were added to 164 g of acetone to manufacture a slurry. The slurry was formed to have a shape of a separator, and then dried at 150° C. for 30 minutes to manufacture a separator. After the crosslinking reaction, the separator was further dried at ambient temperature to complete the separator.

Embodiment 2

[0120] A separator was produced using the same method as in Example 1, except that 0.0072 g of 2,2'-azobis(isobutyronitrile) as an initiator was added to the slurry produced according to Example 1.

Embodiment 3

[0122] A separator was manufactured using the same method as in Example 1, except that the compound represented by Chemical Formula 5 was used instead of the compound represented by Chemical Formula 4 in the slurry of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| solubility (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com