Variable cross-section porous strip-shaped suture line for promoting tendon healing and preparation method thereof

A suture thread with variable cross-section technology, which is applied in the field of biomedical repair materials, can solve the problems of unfavorable cell adhesion and value addition, failure to achieve tendon healing, easy to cause inflammation and infection, etc., to achieve easy promotion, improve affinity, and reduce cumbersomeness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A preparation method of a variable cross-section porous strip-shaped suture for promoting tendon healing, comprising the following steps:

[0031] Step 1: Using two or more fiber materials, with the help of two-dimensional and three-axial weaving technology, and adjusting the weaving process to obtain a prefabricated suture thread with thin lines at both ends and a porous belt in the middle;

[0032] Step 2: obtaining a structurally stable variable cross-section porous ribbon suture through a heat treatment process;

[0033] Step 3: cleaning and drying the suture, and then performing hydrophilic activation pretreatment to obtain surface-activated suture;

[0034] Step 4: dissolving at least one natural polymer material in a corresponding solvent to obtain a polymer solution, then soaking the activated suture in the above solution for 1 hour and then freeze-drying, repeating 3 times to obtain a freeze-dried sample;

[0035] Step 5: Prepare a tannic acid cross-linking ag...

Embodiment 1

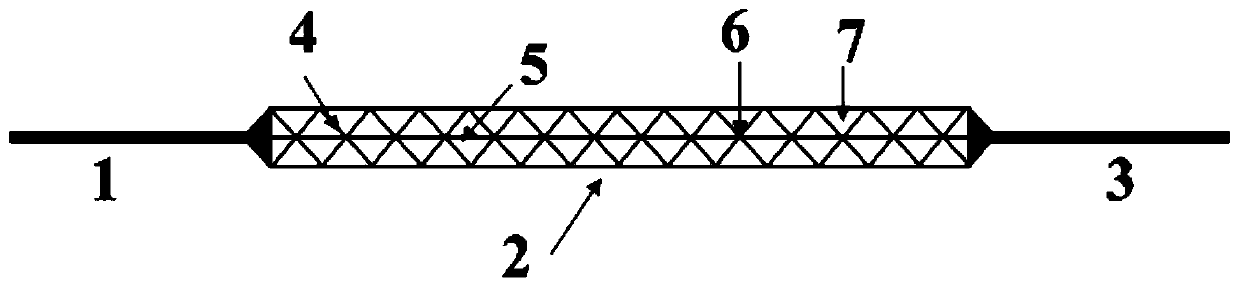

[0045] A variable cross-section porous ribbon suture for promoting tendon healing, comprising such as figure 1 The specific steps for the preparation of the three-section variable-section suture and the hydrogel coating shown are as follows:

[0046] Step 1: Select 55.0dtex ultra-high molecular weight polyethylene multifilament as the braiding yarn 4, 110.0dtex polycaprolactone multifilament as the shaft yarn 5, and then prepare sutures by two-dimensional three-axial weaving technology on a 12-spindle braiding machine When weaving the thin wire structure at both ends, the liner tube is not used; when weaving the middle part, a polytetrafluoroethylene liner tube with a diameter of 1.4 mm is used to obtain a prefabricated suture line with a three-section variable-section structure.

[0047] Step 2: heat-treat the prefabricated suture thread obtained in step 1 in an oven at 80°C for 10 minutes to obtain a structurally stable suture thread with a diameter of 0.3mm at both ends and...

Embodiment 2

[0058] A variable cross-section porous ribbon suture for promoting tendon healing, comprising such as figure 1 The specific steps for the preparation of the three-section variable-section suture and the hydrogel coating shown are as follows:

[0059] Step 1: Select 55.0dtex ultra-high molecular weight polyethylene multifilament as the braiding yarn 4, 110.0dtex polycaprolactone multifilament as the shaft yarn 5, and then prepare sutures by two-dimensional three-axial weaving technology on a 12-spindle braiding machine When weaving the thin wire structure at both ends, the liner tube is not used; when weaving the middle part, a polytetrafluoroethylene liner tube with a diameter of 1.4 mm is used to obtain a prefabricated suture line with a three-section variable-section structure.

[0060] Step 2: heat-treat the prefabricated suture thread obtained in step 1 in an oven at 80°C for 10 minutes to obtain a structurally stable suture thread with a diameter of 0.3mm at both ends and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com