Ammonia gas recovery structure and ammonia gas recovery method for fly ash maintenance workshop

A fly ash and workshop technology is applied to the ammonia recovery structure and the field of ammonia recovery in the fly ash maintenance workshop. and other problems to achieve the effect of reducing secondary pollution, ensuring physical health and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

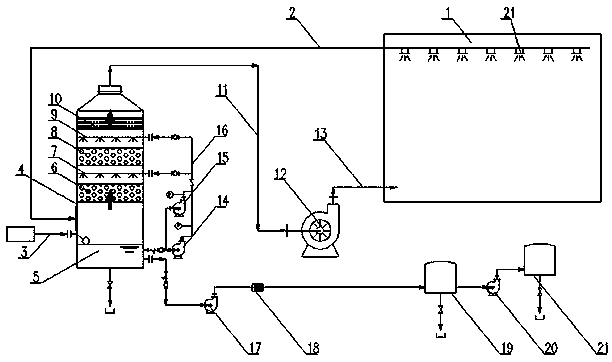

[0022] see figure 1 , the present invention includes a fly ash maintenance workshop 1, a collection air duct 2, a demineralized water input pipeline 3, a washing tower 4, a liquid storage tank 5, a first-stage packing section 6, a first-stage spraying section 7, and a second-stage packing section 8. Second stage spray section 9, defogging plate 10, washing tower outlet air duct 11, centrifugal fan 12, exhaust air duct 13, circulation pump, spray water pipe 16, desalinated water pump 17, filter 18, desalination Brine tank 19, transfer pump 20, SNCR system soft water tank 21 and DCS control system.

[0023] Fly ash maintenance workshop 1 is equipped with ammonia detector and ammonia alarm device. When the ammonia ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com