Negative pressure type walnut shell-kernel separating device and method

A shell kernel separation and negative pressure technology, which is applied in the direction of solid separation, chemical instruments and methods, and separation of solids from solids with airflow, can solve the problems of walnut kernel quality requirements gap, high equipment cost, complex process, etc. , to achieve the effects of strong controllability of pneumatic power, efficient and precise separation, and flexible working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

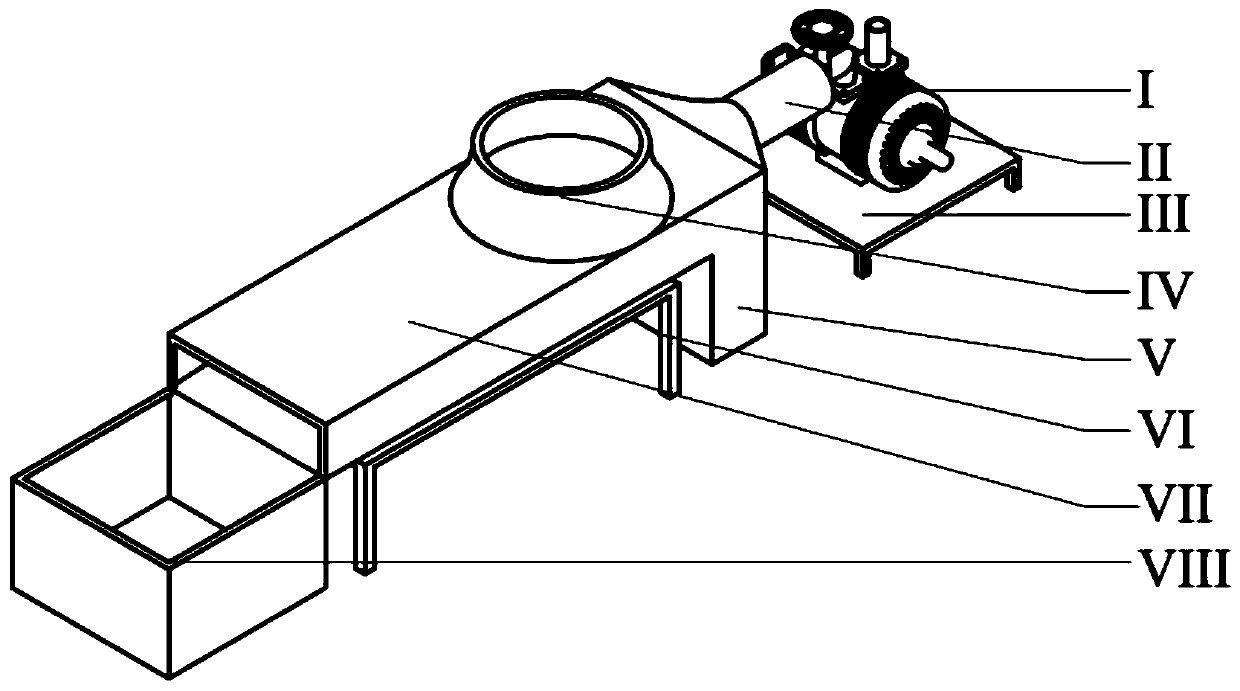

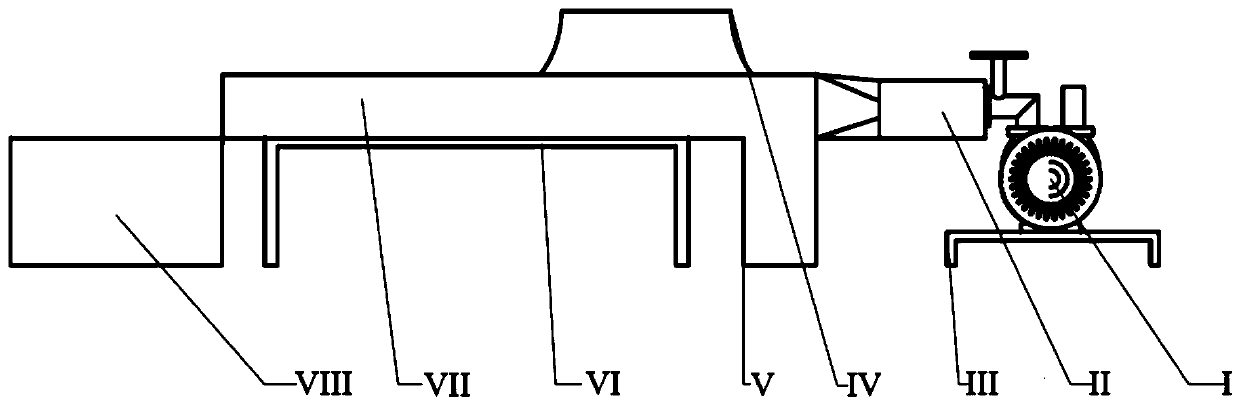

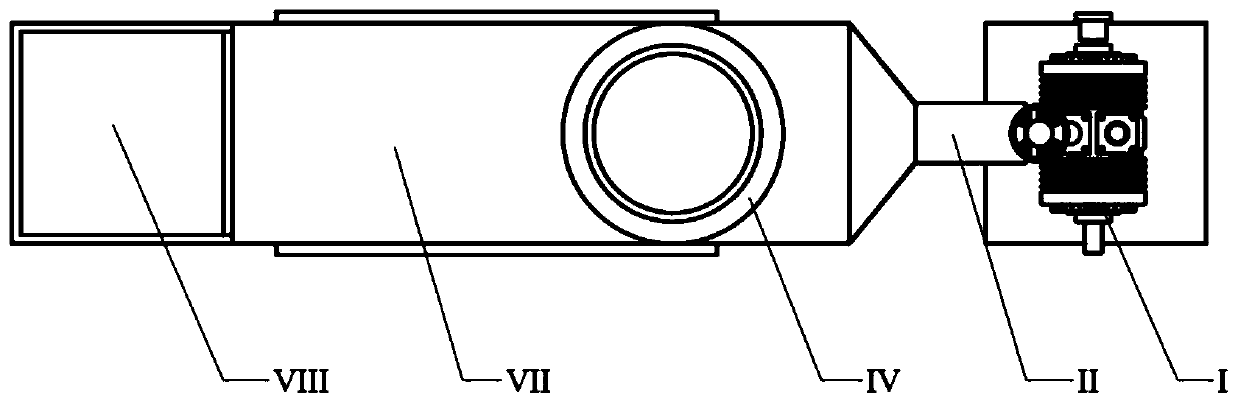

[0052] as attached Figure 1-3 As shown, Embodiment 1 of the present disclosure provides a negative pressure shell kernel separation device, including I-vacuum device, II-vacuum pipeline, III-vacuum device support frame, IV-feeding cylinder, V-walnut shell collection device , VI-separation track support frame, VII-separation track, VIII-walnut kernel collection device.

[0053] Among them, the II-vacuum pipeline is located on the right side of VII-separation track, and the two are sealed with rubber sealing rings. The III-vacuum device is located on the right side of II-vacuum pipeline, and the two are sealed with rubber sealing rings. The separation track is connected, the V-walnut shell collection device is located at the bottom right of the separation track, the external welding is internally connected, and the VIII-walnut kernel collection device is placed at the left bottom of the separation track VII-.

[0054] The lower barrel provides a space for the broken walnut she...

Embodiment 2

[0071] Embodiment 2 of the present disclosure provides a negative pressure walnut shell kernel separation method, using the negative pressure walnut shell kernel separation device described in Embodiment 1 of the present disclosure, comprising the following steps:

[0072] When the walnut shells fall from the end of the lower bottom opening of the lower barrel that is farthest from the peach shell collection device, the walnut shells can fall into the walnut shell collection device under the action of pressure difference and gravity, and the first value range of pressure difference at this time is obtained ;

[0073] When the walnut kernels fall from the end of the lower bottom opening of the lower feeding cylinder closest to the peach shell collection device, the walnut kernels can fall on the edge of the walnut shell collection device near the lower feeding cylinder under the action of pressure difference and gravity, and the first Two ranges of differential pressure;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com