Method for carrying out colorful marking on surface of mirror metal material by using femtosecond laser

A mirror metal and femtosecond laser technology, applied in the field of laser marking, can solve the problems of environmental pollution, colorful effect, and unsteady control of oxide film thickness, so as to achieve rapid material removal and reduce the formation of heat-affected zones or cracks , Improve the effect of product appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

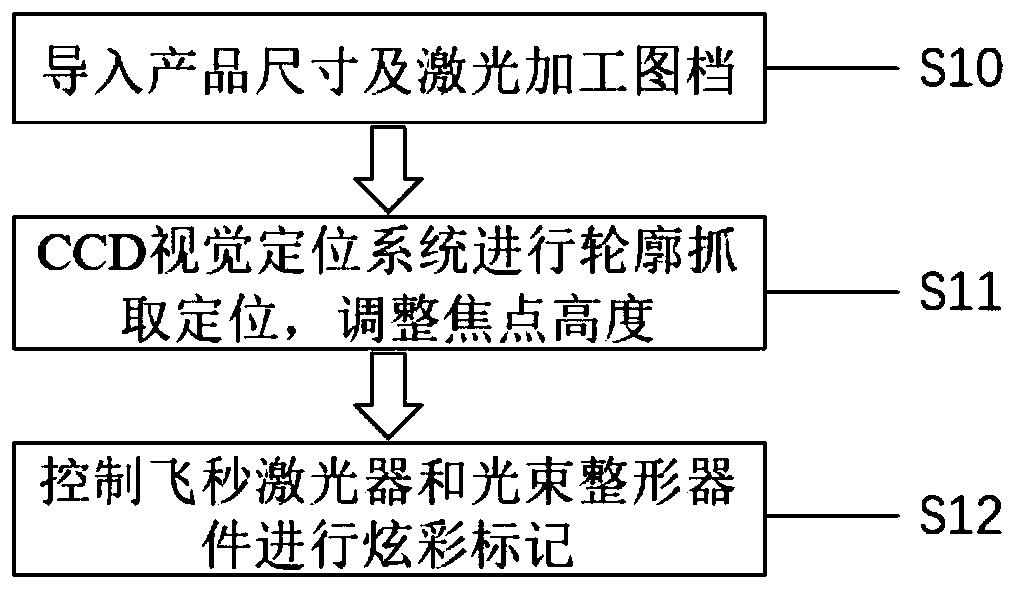

[0033] Such as figure 1 As shown, this embodiment provides a method for using a femtosecond laser to perform colorful marking on the surface of a mirror metal material, including the following steps:

[0034] S10. Input the product shape and size information in the laser processing software system, and read the pre-designed laser processing graphic files;

[0035] S11. Use the CCD vision positioning system to grasp and position the contour of the product surface processing area, and at the same time automatically adjust the focus height to ensure that the product surface is at the laser focus position;

[0036] S12. Control the femtosecond laser and the beam shaping device to perform colorful marking on the surface processing area of the product.

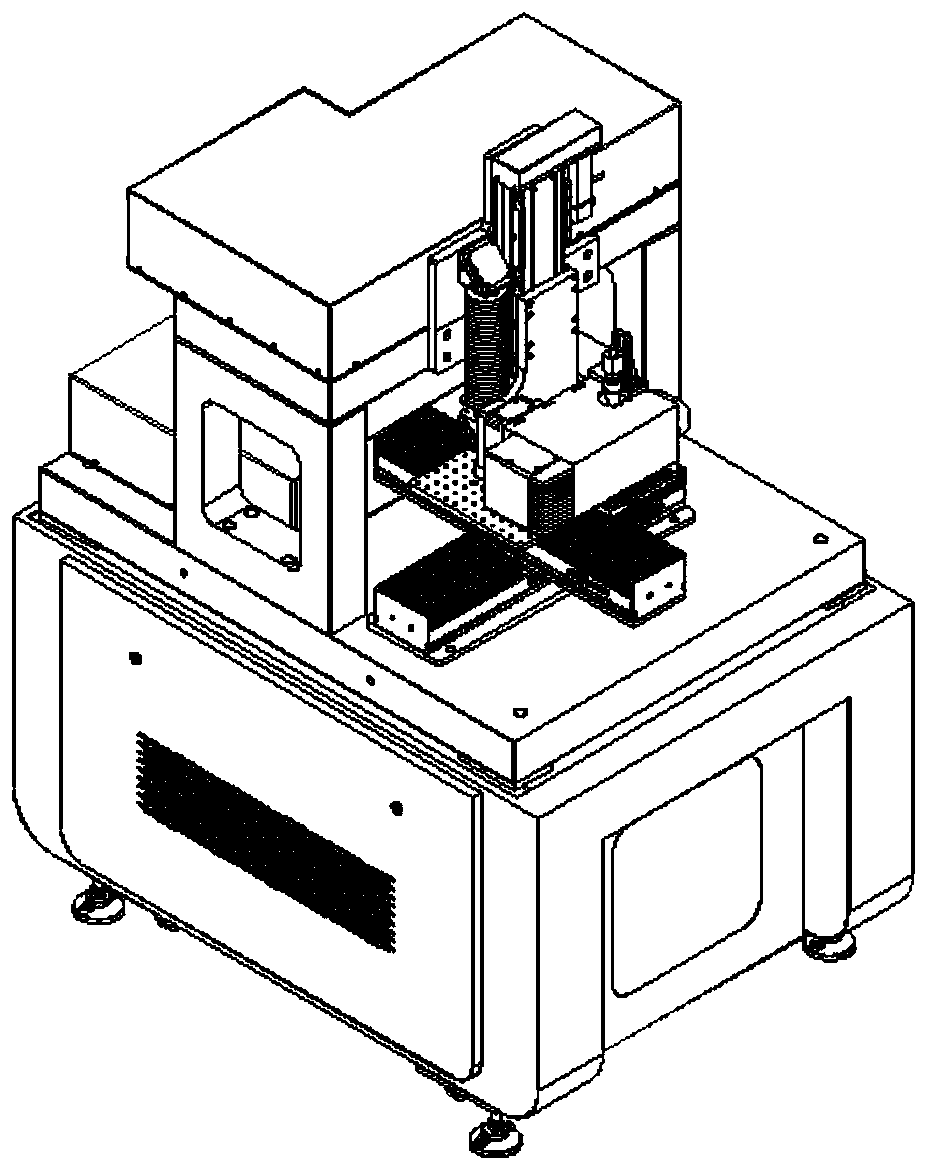

[0037] In the method of using femtosecond laser to perform colorful marking on the surface of mirror metal materials provided by this embodiment, after debugging the laser processing software system and the CCD visual positioning...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com