Degradable transparent bag and preparation method thereof

A transparent bag and nano-cellulose technology, applied in chemical instruments and methods, sustainable manufacturing/processing, climate sustainability, etc., can solve problems such as air pollution, resource waste, and consumption of petroleum resources, so as to improve antibacterial, reduce Destruction of the environment, the effect of increasing the mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

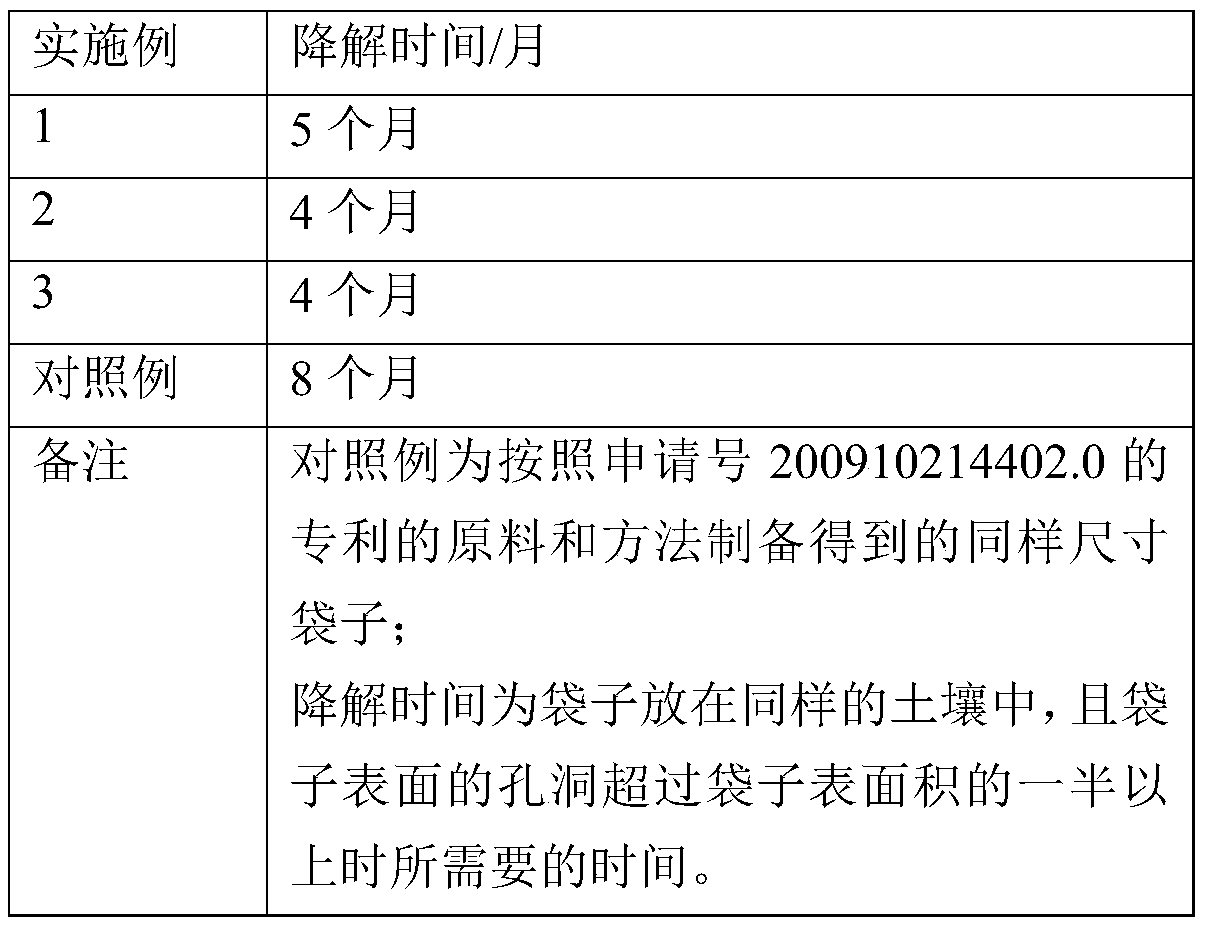

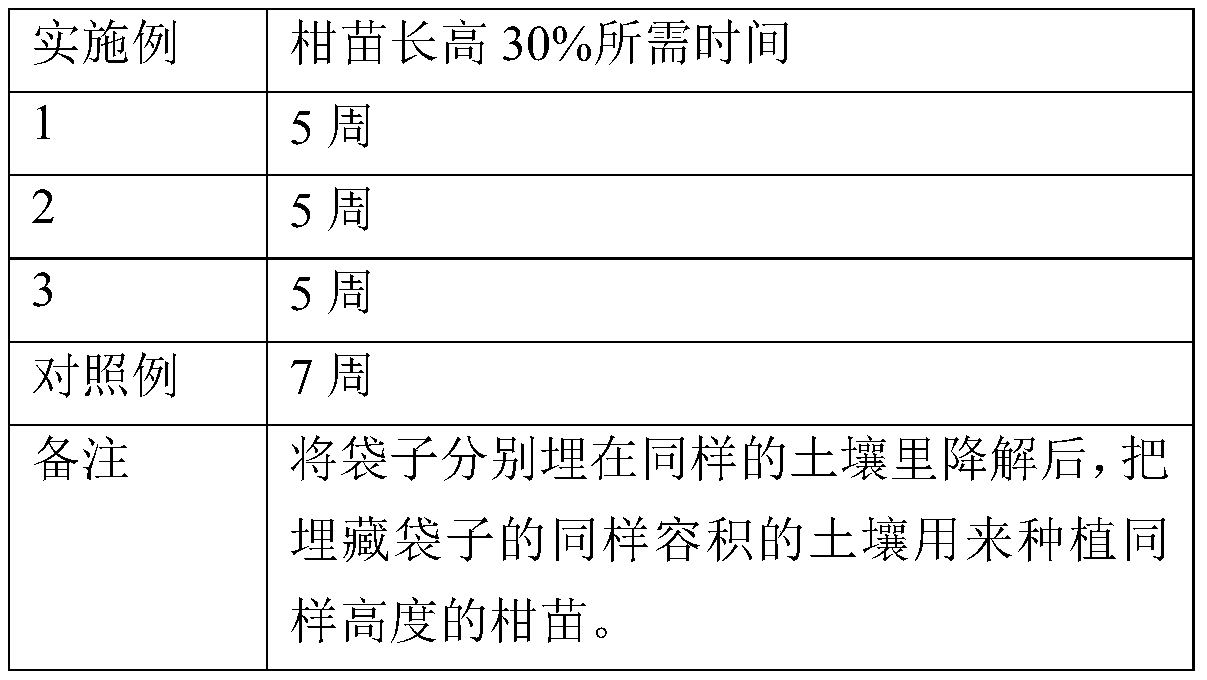

Examples

Embodiment 1

[0032] A degradable transparent bag, prepared from the following raw materials in parts by weight: 30 parts of oyster shell powder, 60 parts of algae powder, 80 parts of cassava powder, 80 parts of straw powder and 60 parts of nanocellulose; the main body of the degradable transparent bag From the outside to the inside, it is mainly composed of the first base material and the second base material, both of which are PLA;

[0033] Specifically, it also includes 15 parts of polylactic acid and 50 parts of bamboo leaf fiber powder;

[0034] Specifically, nanocellulose is extracted from coconut trees.

[0035] The preparation method of the present embodiment comprises the following steps:

[0036] (S1) Weighing raw materials: weighing raw materials according to the ratio of parts by weight;

[0037] (S2) Prepare the first mixture: first mix the oyster shell powder, algae powder and nanocellulose evenly to prepare the first mixture;

[0038] (S3) Prepare the second mixture: add t...

Embodiment 2

[0050] A degradable transparent bag, prepared from the following raw materials by weight: 35 parts of oyster shell powder, 65 parts of algae powder, 90 parts of cassava powder, 90 parts of straw powder and 65 parts of nanocellulose; the main body of the degradable transparent bag From the outside to the inside, it is mainly composed of the first base material and the second base material, both of which are PLA;

[0051] Specifically, it also includes 15 parts of polylactic acid and 50 parts of bamboo leaf fiber powder;

[0052] The preparation method of the present embodiment comprises the following steps:

[0053] (S1) Weighing raw materials: weighing raw materials according to the ratio of parts by weight;

[0054] (S2) Prepare the first mixture: first mix the oyster shell powder, algae powder and nanocellulose evenly to prepare the first mixture;

[0055] (S3) Prepare the second mixture: add the first mixture prepared in (S2) to the reactor and mix with nanocellulose, tap...

Embodiment 3

[0068] A degradable transparent bag, prepared from the following raw materials in parts by weight: 50 parts of oyster shell powder, 80 parts of algae powder, 120 parts of cassava powder, 120 parts of straw powder and 80 parts of nanocellulose; the main body of the degradable transparent bag From the outside to the inside, it is mainly composed of the first base material and the second base material, both of which are PLA;

[0069] Specifically, it also includes 15 parts of polylactic acid and 50 parts of bamboo leaf fiber powder;

[0070] The preparation method of the present embodiment comprises the following steps:

[0071] (S1) Weighing raw materials: weighing raw materials according to the ratio of parts by weight;

[0072] (S2) Prepare the first mixture: first mix the oyster shell powder, algae powder and nanocellulose evenly to prepare the first mixture;

[0073] (S3) Prepare the second mixture: add the first mixture prepared in (S2) to the reactor and mix with nanocel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com