Process for producing melt-blown material

A production process, melt-blown technology, applied in the field of non-woven materials, can solve the problems of limited adsorption content and secondary pollution of melt-blown cloth, and achieve low cost, good charge storage capacity, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

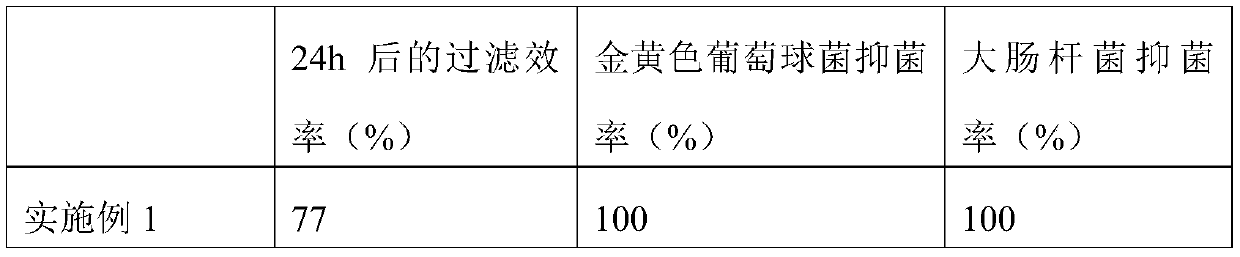

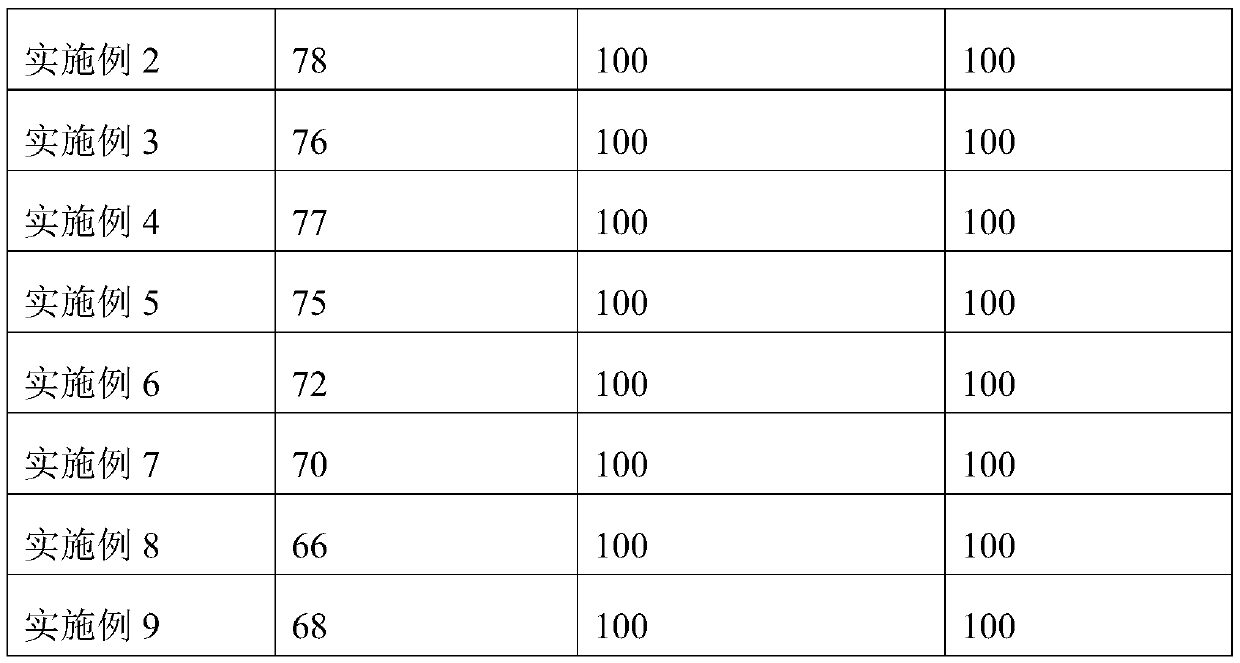

Examples

Embodiment 1

[0023] (1) Add povidone into water to make a 2.5-2.8% povidone solution, add silver nitrate to the solution, and stir thoroughly to obtain a mixed solution; the mass ratio of povidone to silver nitrate is 1:5;

[0024] (2) Add the same volume of 10% ferrous sulfate aqueous solution to the mixture obtained in step (1) at a rate of 0.2 to 0.5 mL / s; react at 55°C for 40 minutes, and then wash and centrifuge after cooling to room temperature , take the precipitate and dry it in vacuum to get nano-silver;

[0025] (3) Put 1 mass part of nano-silver, 40 mass parts of nano-titanium dioxide and 3200 mass parts of polypropylene base material into a high-speed mixer, add 35 parts of silane coupling agent KH560, stir well, and keep the temperature at 100-110°C Dry for 1-3 hours to obtain a mixed masterbatch;

[0026] (4) Add the mixed masterbatch obtained in step (1) into a twin-screw compounding extruder for melt extrusion and granulation to obtain a modified polypropylene base materia...

Embodiment 2

[0029] (1) Adding povidone into water to make a 2.5-2.8% povidone solution, adding silver nitrate to the solution, and fully stirring to obtain a mixed solution;

[0030] (2) Add the same volume of 10% ferrous sulfate aqueous solution to the mixture obtained in step (1) at a rate of 0.2 to 0.5 mL / s; react at 55°C for 40 minutes, and then wash and centrifuge after cooling to room temperature , take the precipitate and dry it in vacuum to get nano-silver;

[0031] (3) Put 1.25 parts by mass of nano-silver, 40 parts by mass of nano-titanium dioxide and 3200 parts by mass of polypropylene base material into a high-speed mixer, add 35 parts of silane coupling agent KH560, stir well, and keep the temperature at 100-110°C Dry for 1-3 hours to obtain a mixed masterbatch;

[0032] (4) Add the mixed masterbatch obtained in step (1) into a twin-screw compounding extruder for melt extrusion and granulation to obtain a modified polypropylene base material.

[0033] (5) The polytetrafluor...

Embodiment 3

[0035] (1) Adding povidone into water to make a 2.5-2.8% povidone solution, adding silver nitrate to the solution, and fully stirring to obtain a mixed solution;

[0036] (2) Add the same volume of 10% ferrous sulfate aqueous solution to the mixture obtained in step (1) at a rate of 0.2 to 0.5 mL / s; react at 55°C for 40 minutes, and then wash and centrifuge after cooling to room temperature , take the precipitate and dry it in vacuum to get nano-silver;

[0037] (3) Put 0.9 parts by mass of nano-silver, 40 parts by mass of nano-titanium dioxide and 3200 parts by mass of polypropylene base material into a high-speed mixer, add 35 parts of silane coupling agent KH560, stir well, and keep the temperature at 100-110°C Dry for 1-3 hours to obtain a mixed masterbatch;

[0038] (4) Add the mixed masterbatch obtained in step (1) into a twin-screw compounding extruder for melt extrusion and granulation to obtain a modified polypropylene base material.

[0039] (5) The polytetrafluoro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com