Antibacterial TPE ultra-soft material, and preparation method and application thereof

A technology of ultra-soft and antibacterial additives, which is applied in the field of antibacterial TPE ultra-soft materials, which can solve the problems of TPE material elasticity decline and high material elasticity requirements, and achieve good market value, good antibacterial performance, and sufficient elasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

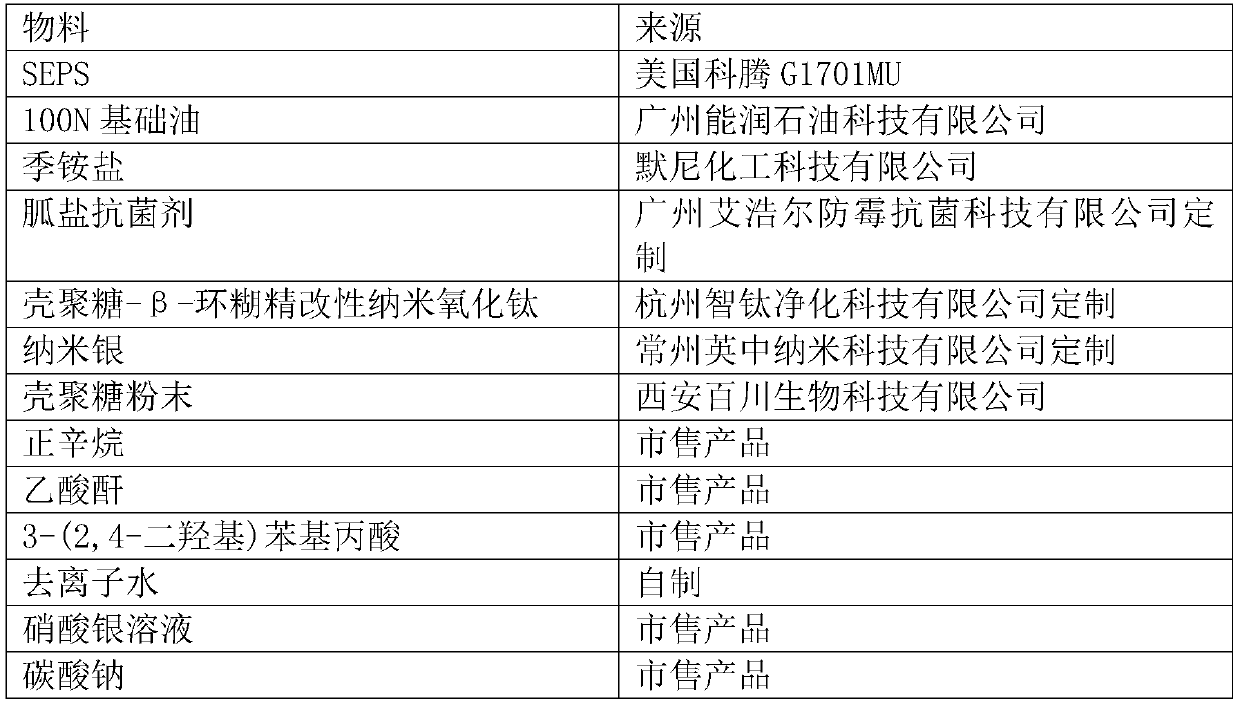

[0061] materials percentage content SEPS 15% 100N base oil 82% Quaternary ammonium salt 3%

[0062] Table 2

[0063] The present embodiment 100N base oil viscosity is 80000cps;

[0064] The antibacterial TPE supersoft material of this embodiment, the preparation method comprises the following steps:

[0065] Step 1. Add SEPS and 100N base oil to the mixer, and stir at a speed of 30r / min for 30min until the 100N base oil is completely absorbed;

[0066] Step 2: Add antibacterial additives to the mixer and stir evenly;

[0067] Step 3, melt extruding and pelletizing.

[0068] District 1 second district third district District 4 District 5 Sixth District District 7 180℃ 183℃ 185℃ 187℃ 185℃ 185℃ 183℃

[0069] table 3

[0070] In the processing engineering, the temperature fluctuation of each temperature zone mentioned above should not exceed 5°C, otherwise it needs to be shut down for debugging.

[0071] Th...

Embodiment 2

[0073] materials percentage content SEPS 19% 100N base oil 79% Guanidine antibacterial agent 2%

[0074] Table 4

[0075] The viscosity of the 100N base oil in this example is 90000cps; the antibacterial TPE supersoft material obtained in this example is injection molded to obtain a sex toy as application example 2.

Embodiment 3

[0077] materials percentage content SEPS 24% 100N base oil 73% Chitosan-β-cyclodextrin modified nano-titanium oxide 3%

[0078] table 5

[0079] The viscosity of the 100N base oil in this example is 100,000 cps; the antibacterial TPE supersoft material obtained in this example is injection-molded to obtain a sex toy as application example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| degree of deacetylation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com