Method for improving performance of tin-based Babbitt alloy by adding Ni60A

A technology of tin-based babbitt alloy and performance, applied in the field of bearing bush wear resistance, can solve the problems of low hardness, reduced wear performance of tin-based babbitt alloy, poor wear resistance, etc., and achieve the effect of improving surface hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] One by adding Ni 60A The method for improving the performance of tin-based babbitt alloy comprises the steps of:

[0029] S1, take an appropriate amount of tin-based Babbitt alloy powder, nickel-chromium-boron-silicon alloy powder Ni 60A And metal TiN powder, wherein the content of tin-based Babbitt alloy powder is 63-87%, nickel-chromium borosilicate powder Ni 60A The content of TiN powder is 5-25%; the content of metal TiN powder is 8-12%;

[0030] S2, tin-based Babbitt alloy powder, nickel chromium borosilicate powder Ni 60A and metal TiN powder are added into the mixer for mixing work, so that the tin-based Babbitt alloy powder, nickel-chromium-borosilicate alloy powder Ni 60A Fully mixed with metal TiN powder for 6-8 hours to get spray powder;

[0031] S3. Add the mixed spray powder to the plasma spray equipment, and use the plasma spray equipment to evenly spray the spray powder on the H62 brass surface with a size of 25*50*2-3mm;

[0032] Among them, the mod...

Embodiment 2

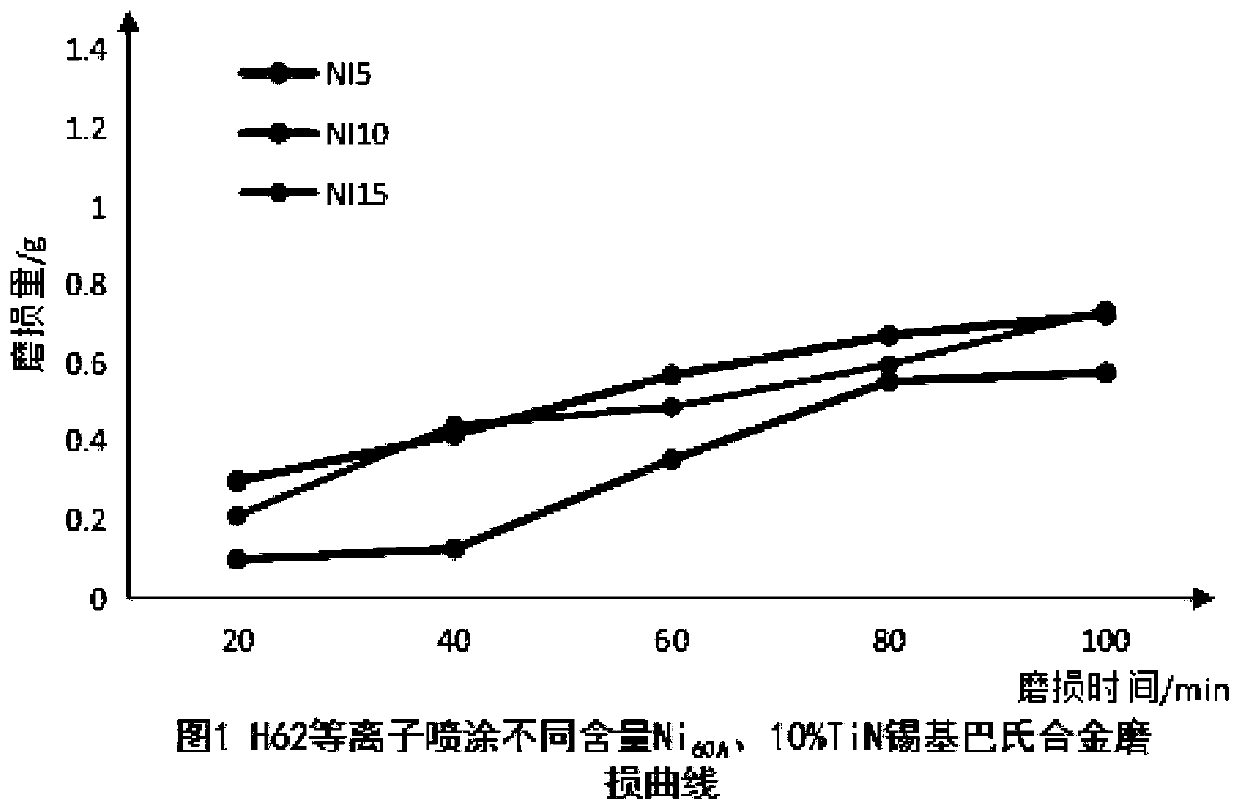

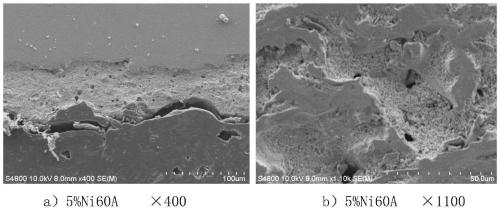

[0041] S1, take an appropriate amount of tin-based Babbitt alloy powder, nickel-chromium-boron-silicon alloy powder Ni 60A And metal TiN powder, wherein the content of tin-based Babbitt alloy powder is 85%, nickel-chromium borosilicate powder Ni 60A The content of TiN powder is 5%; the content of metal TiN powder is 10%;

[0042] S2, tin-based Babbitt alloy powder, nickel chromium borosilicate powder Ni 60A and metal TiN powder are added into the mixer for mixing work, so that the tin-based Babbitt alloy powder, nickel-chromium-borosilicate alloy powder Ni 60A Fully mixed with metal TiN powder for 6-8 hours to get spray powder;

[0043] S3. Add the mixed spray powder into the plasma spray equipment, and use the plasma spray equipment to evenly spray the spray powder on the H62 brass surface with a size of 25*50*2-3mm;

[0044] Among them, the model of the plasma spraying equipment is PK-80Z-II. The equipment performance and spraying parameters are selected as shown in Table...

Embodiment 3

[0053] S1, take an appropriate amount of tin-based Babbitt alloy powder, nickel-chromium-boron-silicon alloy powder Ni 60A And metal TiN powder, wherein the content of tin-based Babbitt alloy powder is 80%, nickel-chromium borosilicate powder Ni 60A The content of TiN powder is 10%; the content of metal TiN powder is 10%;

[0054] S2, nickel chromium borosilicate powder Ni 60A And metal TiN powder and tin-based Babbitt alloy powder are added to the mixer for mixing work, so that tin-based Babbitt alloy powder, nickel-chromium borosilicate powder Ni 60A Fully mixed with metal TiN powder for 6-8 hours to get spray powder;

[0055] S3. Add the mixed spray powder into the plasma spray equipment, and use the plasma spray equipment to evenly spray the spray powder on the H62 brass surface with a size of 25*50*2-3mm;

[0056] Among them, the model of the plasma spraying equipment is PK-80Z-II. The equipment performance and spraying parameters are selected as shown in Table 1. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Microhardness | aaaaa | aaaaa |

| Surface microhardness | aaaaa | aaaaa |

| Coefficient of friction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com