Preparation method of airplane hydraulic oil tank piston rod surface coating

A surface coating, aircraft hydraulic technology, applied in the direction of coating, metal material coating technology, metal processing equipment, etc., can solve the problems of low dilution rate, different working environment, etc., to reduce environmental pollution, improve surface hardness and durability. abrasive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

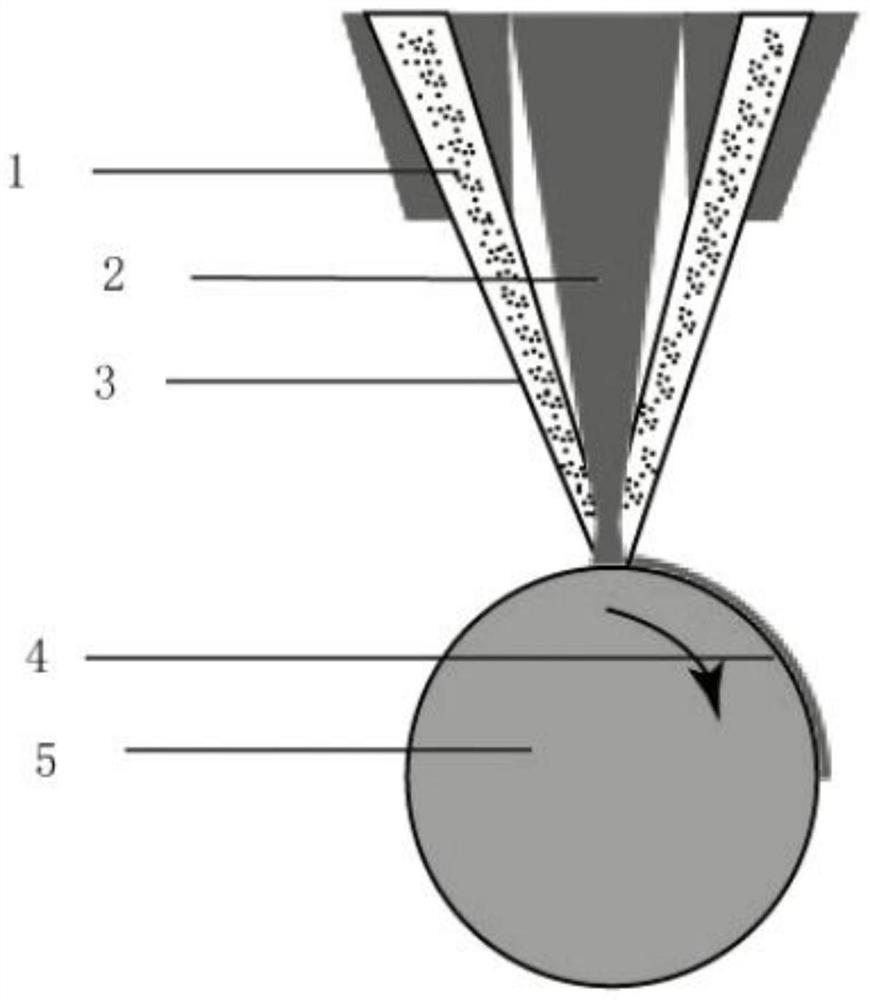

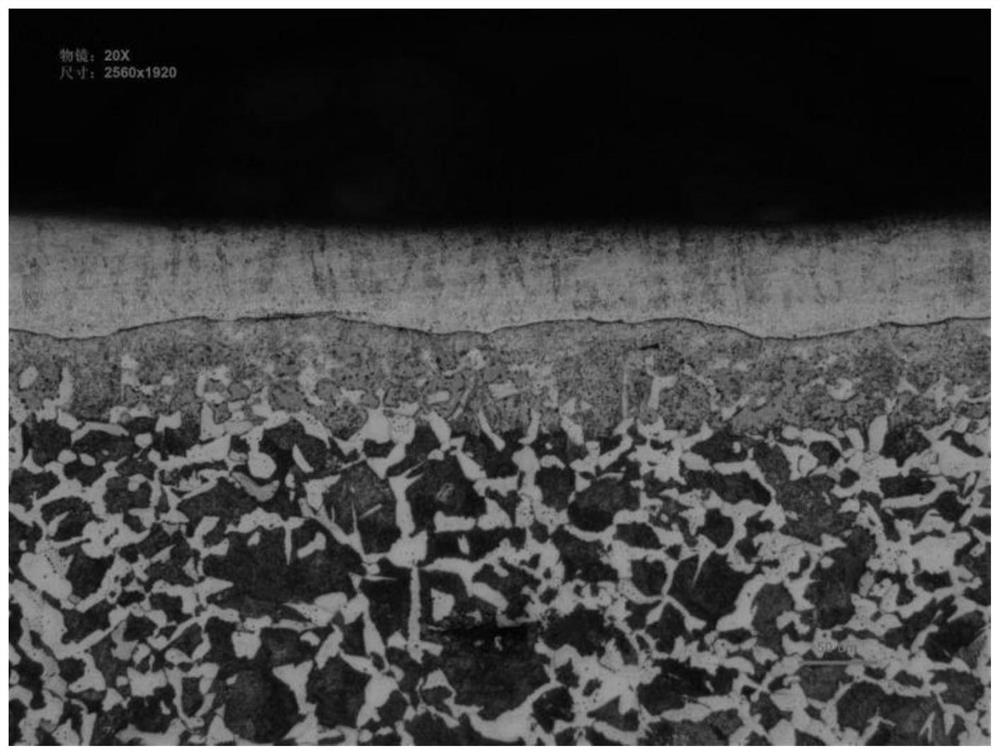

[0026] like Figure 1 to Figure 4 As shown, a preparation method of the surface coating of the piston rod of an aircraft hydraulic oil tank, the specific steps are as follows:

[0027] S1. The material of coating 4 is Fe-based nanophase composite material, and the mass percentage of each component is as follows: C: 0.28wt%, Si: 0.90wt%, Mn: 0.80%, Cr: 0.80%, Ni: 0.02wt%, P : 0.02wt%, S: 0.02wt%, Nanoparticle WC: 0.5wt%, Nanoparticle TiC: 0.5wt%, Nanoparticle NbC: 0.1wt%, Fe balance. The powder particle size of the Fe-based material is 50-100 μm, spherical or nearly spherical, and the fluidity is less than 20s / 50g, and the powder is vacuum-dried for use, the temperature is 100°C, and the time is 3h;

[0028] S2. Sandblast the surface of the piston rod 5 and clean it with alcohol;

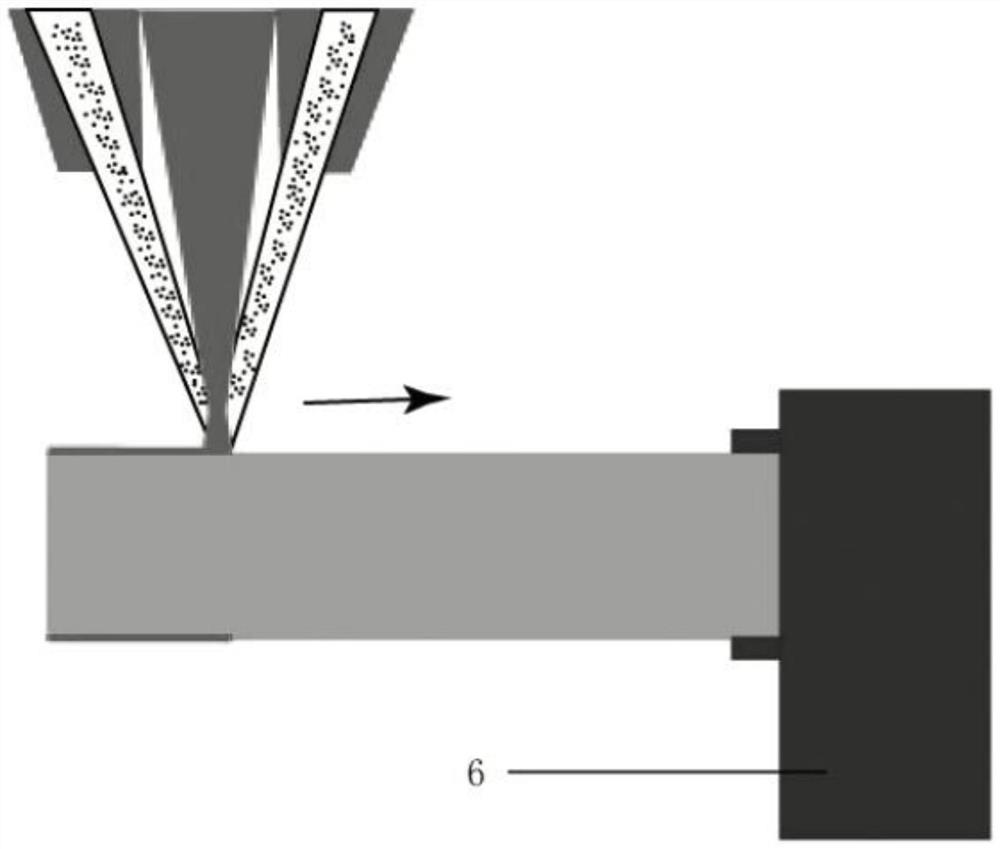

[0029] S3. Use ultra-high-speed laser cladding on the surface of the piston rod 5 to prepare the coating 4, such as figure 1 As shown, the piston rod 5 is clamped on the high-speed turntable 6, wh...

Embodiment 2

[0036] like Figure 1 to Figure 4 As shown, a preparation method of the surface coating of the piston rod of an aircraft hydraulic oil tank, the specific steps are as follows:

[0037] S1. The material of coating 4 is Fe-based nanophase composite material, and the mass percentage of each component is as follows: C: 0.3wt%, Si: 1.0wt%, Mn: 0.9wt%, Cr: 1.1wt%, Ni: 0.03wt% , P: 0.02wt%, S: 0.02wt%, Nanoparticles WC: 1wt%, Nanoparticles TiC: 1wt% Nanoparticles NbC: 0.5wt%, Fe balance. The powder particle size of the Fe-based material is 50-100 μm, spherical or nearly spherical, and the fluidity is less than 20s / 50g, and the powder is vacuum-dried for use, the temperature is 100°C, and the time is 3h;

[0038] S2. Sandblast the surface of the piston rod 5 and clean it with alcohol;

[0039] S3. Use ultra-high-speed laser cladding on the surface of the piston rod 5 to prepare the coating 4, such as figure 1As shown, the piston rod 5 is clamped on the high-speed turntable 6, while...

Embodiment 3

[0046] like Figure 1 to Figure 4 As shown, a preparation method of the surface coating of the piston rod of an aircraft hydraulic oil tank, the specific steps are as follows:

[0047] S1. The material of coating 4 is Fe-based nanophase composite material, and the mass percentage of each component is as follows: C: 0.34wt%, Si: 1.2wt%, Mn: 1.1wt%, Cr: 1.5wt%, Ni: 0.03wt% , P: 0.025wt%, S: 0.025wt%, Nanoparticles WC: 1wt%, Nanoparticles TiC: 1.5wt% Nanoparticles NbC: 0.5wt%, Fe balance. The powder particle size of the Fe-based material is 50-100 μm, spherical or nearly spherical, and the fluidity is less than 20s / 50g, and the powder is vacuum-dried for use, the temperature is 100°C, and the time is 3h;

[0048] S2. Sandblast the surface of the piston rod 5 and clean it with alcohol;

[0049] S3. Use ultra-high-speed laser cladding on the surface of the piston rod 5 to prepare the coating 4, such as figure 1 As shown, the piston rod 5 is clamped on the high-speed turntable 6,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com