Preparation method of sulfydryl-grafted mesoporous organic polymer

A polymer, polymer solution technology, applied in chemical instruments and methods, water/sludge/sewage treatment, adsorbed water/sewage treatment, etc., can solve problems such as health problems, high toxicity and biodegradability, and achieve operational Simple, improved mechanical properties, microscopic morphology and the effect of optimization of dispersion state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

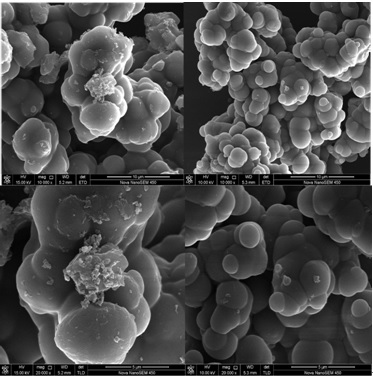

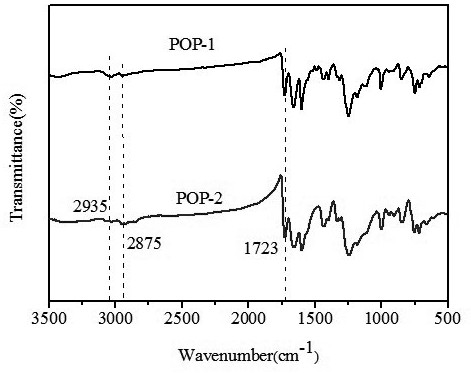

[0037] Under oil bath conditions, in a 250 mL two-necked flask with a stirring bar, in N2 atmosphere, add 1.325 g of 1,3,5-benzenetricarboxylic acid chloride, add 1.155 g of biphenyl, and add 2.5 g of chloride Aluminum was dissolved in 90 mL of dichloromethane, and the heating temperature was set to 55 °C. Stir at room temperature for 15 h. After cooling, carry out suction filtration, and then wash the filter residue with dichloromethane, methanol, and deionized water, 4 times for each washing, and pour 25 mL of dichloromethane, methanol, and deionized water into each time. Afterwards, the filter residue was subjected to Soxhlet extraction, the Soxhlet extraction solvent was deionized water, and the extraction time was 12 hours. After the Soxhlet extraction, the polymer was put into a vacuum drying oven at 120° C. to dry to obtain a yellow-brown powder carbonyl-containing organic polymer ( POP-1).

[0038] Put 1.00 g of carbonyl-containing organic polymers in a round-bottome...

Embodiment 2

[0041] Under oil bath conditions, in a 250 mL two-necked flask with a stirring bar, in N2 atmosphere, add 1.325 g of 1,3,5-benzenetricarboxylic acid chloride, add 1.155 g of biphenyl, and add 4 g of chloride Aluminum was dissolved in 90 mL of dichloromethane, and the heating temperature was set to 55 °C. Stir at room temperature for 15 h. After cooling, carry out suction filtration, and then wash the filter residue with dichloromethane, methanol, and deionized water, 4 times for each washing, and pour 25 mL of dichloromethane, methanol, and deionized water into each time. Afterwards, the filter residue was subjected to Soxhlet extraction. The Soxhlet extraction solvent was deionized water, and the extraction time was 12 hours. After the Soxhlet extraction, the polymer was put into a vacuum drying oven to dry at 120° C. to obtain a brown powder carbonyl-containing organic polymer (POP -2).

[0042] Put 1.00 g of carbonyl-containing organic polymer (POP) in a round bottom flas...

Embodiment 3

[0045] Under oil bath conditions, in a 250 mL two-necked flask with a stirring bar, in N2 atmosphere, add 1.325 g of 1,3,5-benzenetricarboxylic acid chloride, add 1.735 g of biphenyl, and add 4 g of chloride Aluminum was dissolved in 90 mL of dichloromethane, and the heating temperature was set to 55 °C. Stir at room temperature for 15 h. After cooling, carry out suction filtration, and then wash the filter residue with dichloromethane, methanol, and deionized water, 4 times for each washing, and pour 25 mL of dichloromethane, methanol, and deionized water into each time. Afterwards, the filter residue was subjected to Soxhlet extraction. The Soxhlet extraction solvent was deionized water, and the extraction time was 12 hours. After the Soxhlet extraction, the polymer was dried in a vacuum oven at 120° C. to obtain a brown powder carbonyl-containing organic polymer.

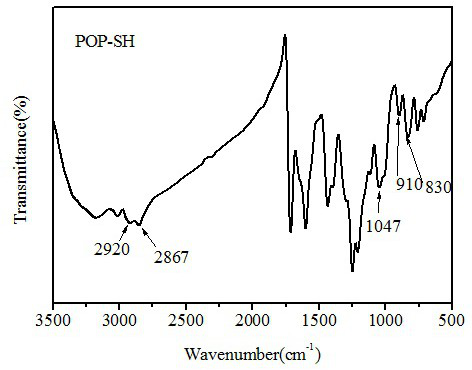

[0046] Put 1.00 g of carbonyl-containing organic polymer (POP) in a round bottom flask, add 0.6 g of 2-aminoe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com