High-surface-hardness tool steel with excellent 800MPa electroplating performance and production method

A production method, 800mpa technology, applied in the direction of manufacturing tools, process efficiency improvement, workpiece surface treatment equipment, etc., can solve the problems of unqualified electroplating and high heat treatment cost, achieve energy saving and consumption reduction, electroplating qualification rate of 100%, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

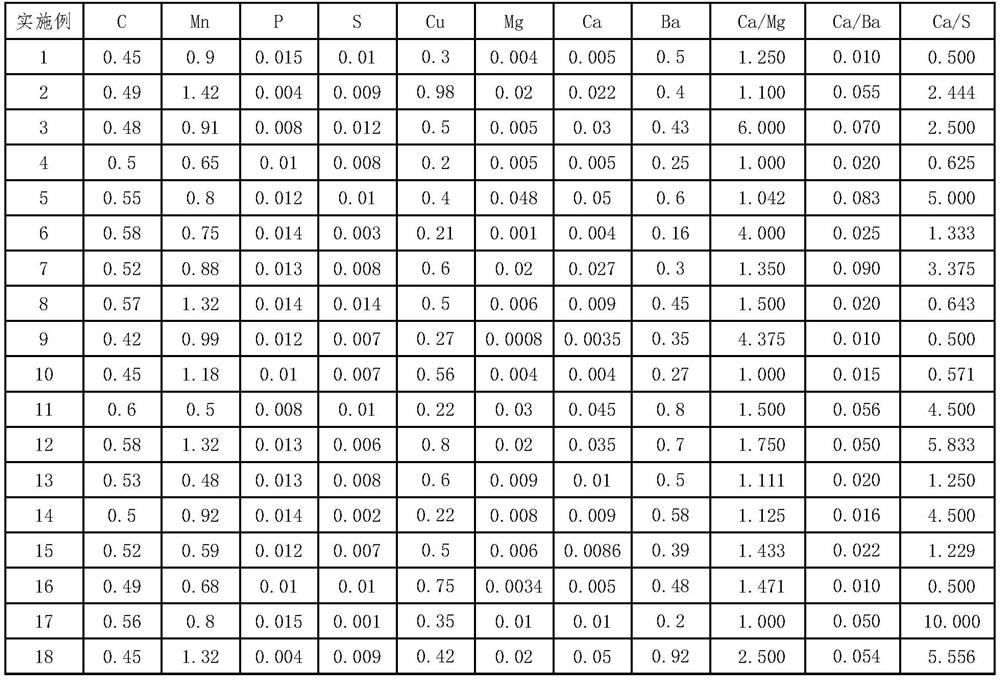

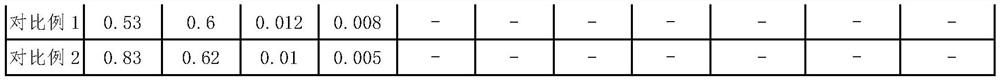

[0039] The invention is a high surface hardness tool steel with excellent 800MPa electroplating performance. The chemical composition of the tool steel is calculated by weight percentage: C 0.40%-0.60%, Mn 0.4%-1.5%, Ca 0.0005%-0.05%, Mg0.0005%~0.05%, Ba 0.1%~1.0%, Ca / Ba≥0.05, Ca / S≥0.5, Ca / Mg≥1, Cu 0.2%~1.0%, P≤0.020%, S≤0.015%, The balance is Fe and unavoidable impurities.

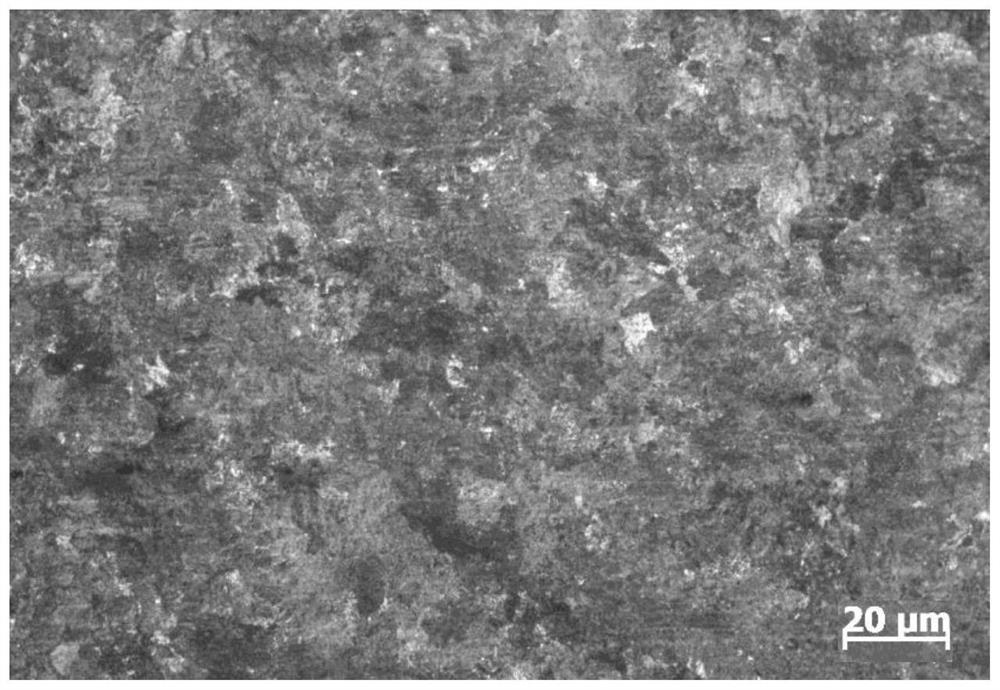

[0040] like figure 1 As shown, the tool steel has the following organizational characteristics:

[0041] 1) The internal structure of the steel plate is pearlite, the size of the pearlite group is 10μm-20μm, the tensile strength of the matrix is 800MPa-900MPa, and the yield ratio is less than 70%;

[0042] 2) There is a troostite layer with CuBaC particles dispersedly distributed under the surface of the steel plate and the distance between the sheets is less than 100nm. The depth of the troostite layer is not less than 10% of the thickness of the steel plate. The maximum diameter of the particles in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com