Novel natto yoghourt and preparation method thereof

A technology of natto and yogurt, applied to milk preparations, bacteria used in food preparation, dairy products, etc., can solve the problems of simplification of nutritional components and functions of ordinary yogurt, poor flavor of fermented products of natto bacteria, etc., and achieve Effects of preventing cardiovascular disease and enhancing health care value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

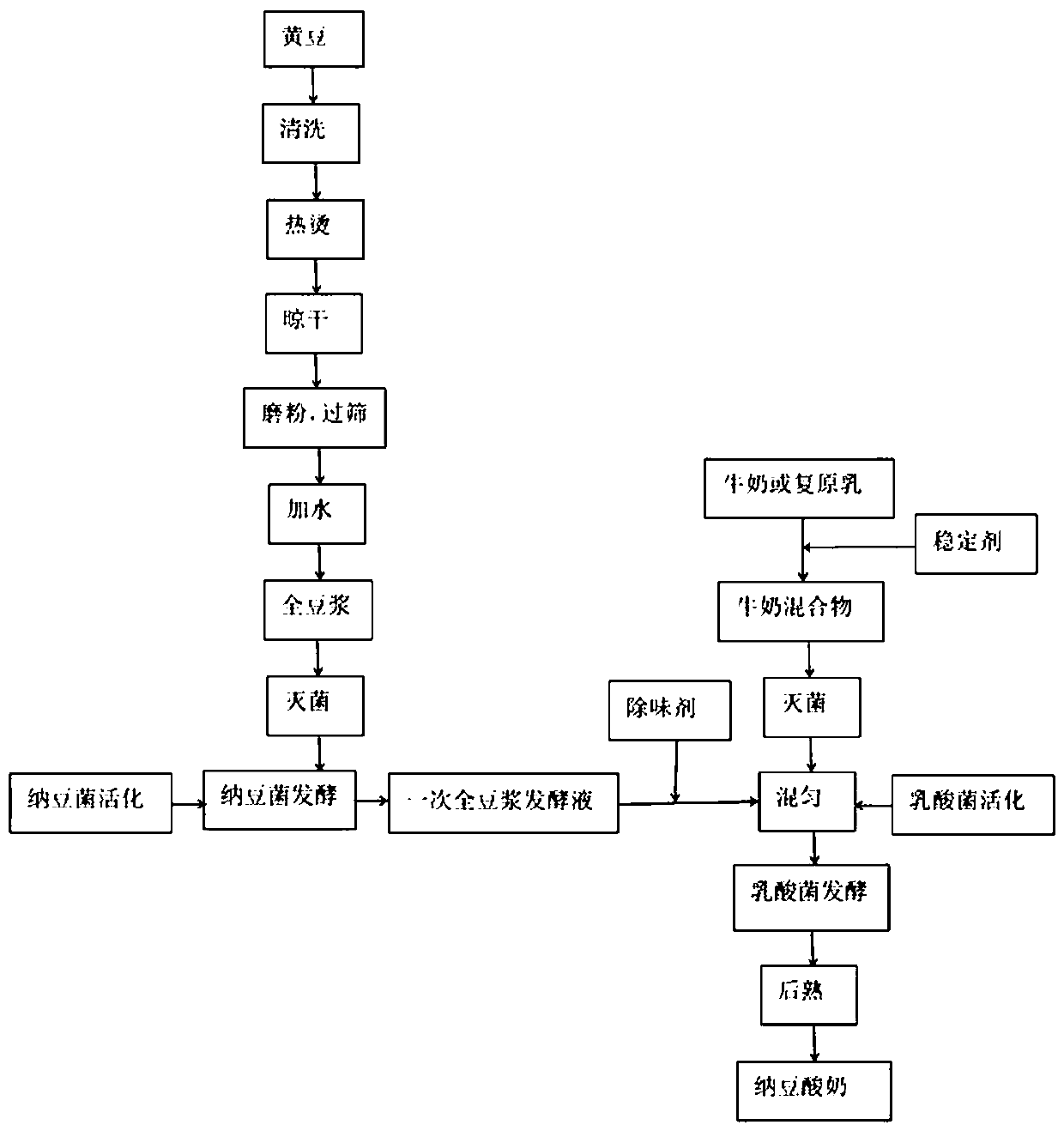

Method used

Image

Examples

Embodiment 1

[0032] The finely selected soybeans were washed three times, soaked in hot water at 95°C for 3 min, dried in the air, pulverized by a grinder, and passed through a 100-mesh sieve until all the soybean powder passed through to prepare whole soybean powder. Weigh 10 g of whole bean flour, add 100 mL of drinking water, mix well, and sterilize at 115°C for 30 min. Bacillus natto was activated in the whole soybean powder liquid at 37°C for 6 hours. After the whole soybean milk was cooled to room temperature, the activated Bacillus natto was inoculated and fermented at 140 r / min at 37°C for 3 hours to obtain a primary fermentation liquid. Add 1.5g of superfine shell powder and 0.6g of edible agar in a fermentation liquid, and mix well. Add 1.5 g of acetylated distarch phosphate, 1.5 g of protein powder, 0.21 g of citric acid and 0.105 g of sodium citrate to 200 mL of fresh milk, mix well and pasteurize at 90°C for 5 min. After the milk is cooled, mix it with 100 mL of primary ferme...

Embodiment 2

[0034]The finely selected soybeans were washed 3 times, soaked in hot water at 95°C for 3 min, dried in the air, pulverized by a grinder, and passed through a 100-mesh sieve until all the soybean powder passed through to prepare whole soybean powder. Weigh 10 g of whole bean flour, add 120 mL of drinking water, mix well, and sterilize at 115°C for 30 min. Bacillus natto was activated in the whole soybean powder liquid at 37°C for 5 hours. After the whole soybean milk was cooled to room temperature, the activated Bacillus natto was inoculated and fermented at 140 r / min at 37°C for 4 hours to obtain a fermented liquid. Add 2.9g of superfine shell powder and 0.9g of agar in a fermentation liquid, and mix well. . Add 2 g of acetylated distarch phosphate, 2 g of protein powder, 0.26 g of citric acid and 0.13 g of sodium citrate to 360 mL of fresh milk, mix well and pasteurize at 90°C for 5 min. After the milk is cooled, mix it with 120 mL of primary fermentation liquid, add activ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com