Pretreatment process of high-salinity wastewater in epoxy resin production

An epoxy resin and pretreatment technology, applied in water/sewage treatment, natural water treatment, water treatment parameter control, etc., can solve the problems of biochemical treatment efficiency decline, evaporator efficiency decline, high COD content, etc., to reduce treatment costs , Simplified operation, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

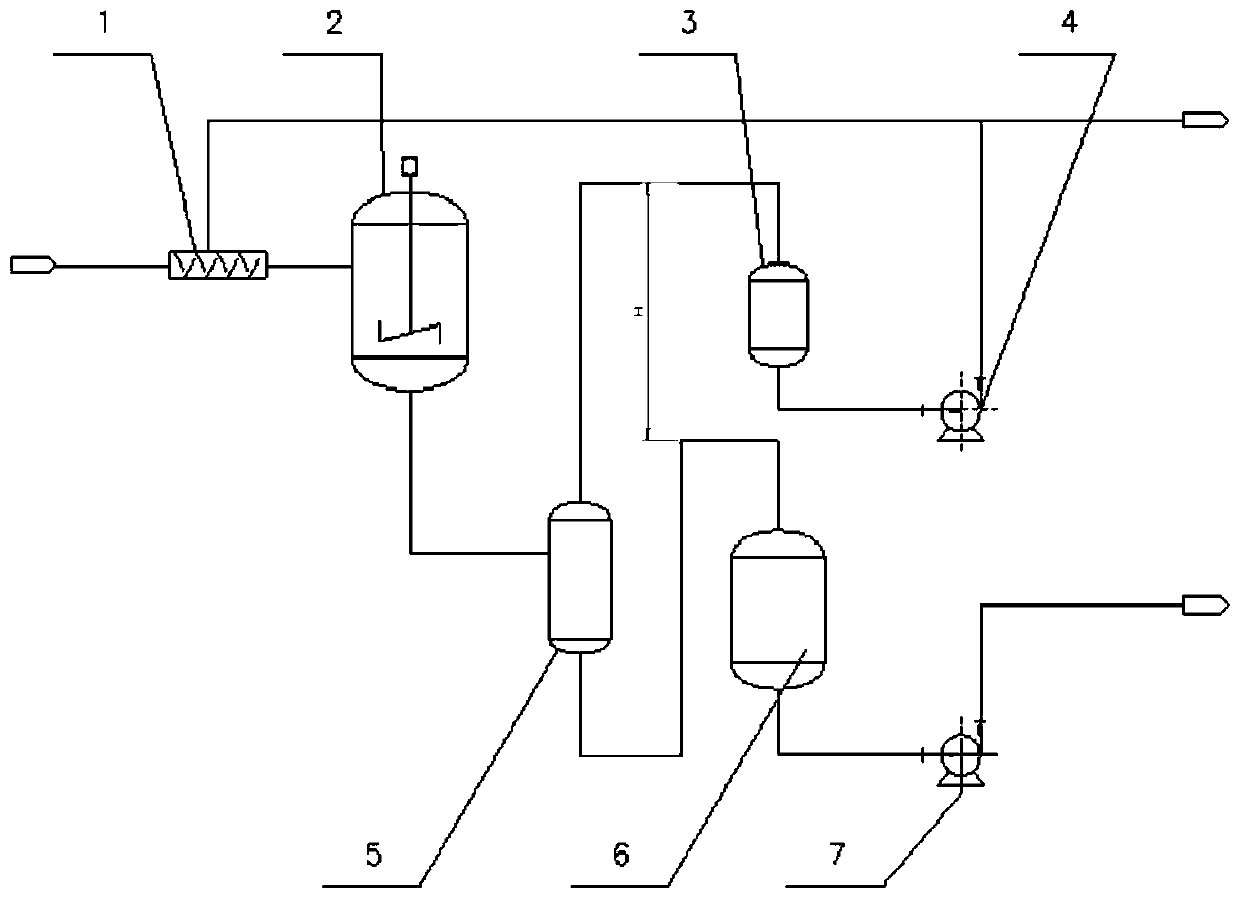

Image

Examples

Embodiment 1

[0041] A pretreatment process for high-salinity waste water in the production of epoxy resin, said process comprising the steps of:

[0042] (1) The high salinity waste water to be treated and toluene are added into Venturi mixer 1 and mixed; waste water:

[0043] The mass ratio of toluene is 5:1;

[0044] (2) Add the mixed material obtained in step (1) into the stirred tank 2, and stir for 60min at a temperature of 90°C and a stirring speed of 300rpm / min for stirring and extraction;

[0045] (3) The material that is mixed evenly and has reached the extraction effect enters the settling tank 5 from the middle and upper part and settles for 30 minutes, automatically stratified;

[0046] Height difference H=[(density of waste water-toluene density)×(height of discharge pipe of waste water-two-phase interface height)] / toluene density; (600mm)

[0047] (4) The layered toluene containing aging resin and organic solvent overflows from the top of the tank to the toluene buffer tank...

Embodiment 2

[0050] A pretreatment process for high-salinity waste water in the production of epoxy resin, said process comprising the steps of:

[0051] (1) The high salinity waste water to be treated and toluene are added into Venturi mixer 1 and mixed; waste water:

[0052] The mass ratio of toluene is 20:1;

[0053] (2) Add the mixed material obtained in step (1) into the stirred tank 2, and stir for 30min at a temperature of 70°C and a stirring speed of 400rpm / min for stirring and extraction;

[0054] (3) The material that is mixed evenly and has reached the extraction effect enters the settling tank 5 from the middle and upper part and settles for 20 minutes, automatically stratified;

[0055] Height difference H=[(density of waste water-toluene density)×(height of discharge pipe of waste water-two-phase interface height)] / toluene density; (600mm)

[0056] (4) The layered toluene containing aging resin and organic solvent overflows from the top of the tank to the toluene buffer tan...

Embodiment 3

[0059] A pretreatment process for high-salinity waste water in the production of epoxy resin, said process comprising the steps of:

[0060](1) The high salinity waste water to be treated and toluene are added into Venturi mixer 1 and mixed; waste water:

[0061] The mass ratio of toluene is 15:1;

[0062] (2) Add the mixed material obtained in step (1) into the stirred tank 2, and stir for 45min at a temperature of 80°C and a stirring speed of 350rpm / min to carry out stirring and extraction;

[0063] (3) The material that is mixed evenly and has reached the extraction effect enters the settling tank 5 from the middle and upper part and settles for 25 minutes, automatically stratified;

[0064] Height difference H=[(density of waste water-toluene density)×(height of discharge pipe of waste water-two-phase interface height)] / toluene density; (600mm)

[0065] (4) The layered toluene containing aging resin and organic solvent overflows from the top of the tank to the toluene bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com