Preparation method of p-methylstyrene/1-octene co-modified hydrogen-containing silicone oil release agent

A technology of p-methylstyrene and hydrogen-containing silicon is applied in the preparation field of p-methylstyrene/1-octene co-modified hydrogen-containing silicone oil mold release agent, and can solve the problem of tetramethylhydrogencyclotetrasiloxane Expensive, cumbersome steps, high cost problems, to achieve the effect of saving reaction steps and time, low cost of raw materials, and good quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

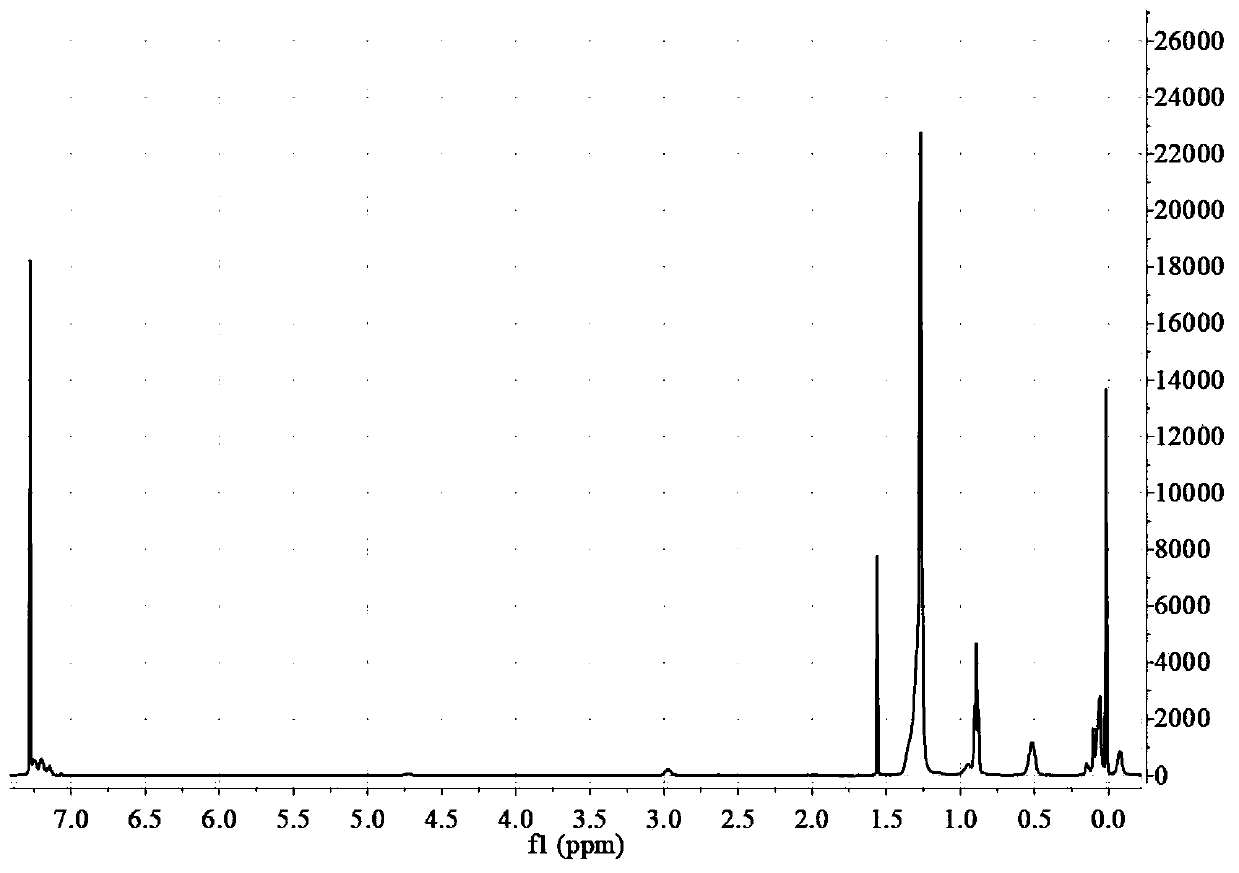

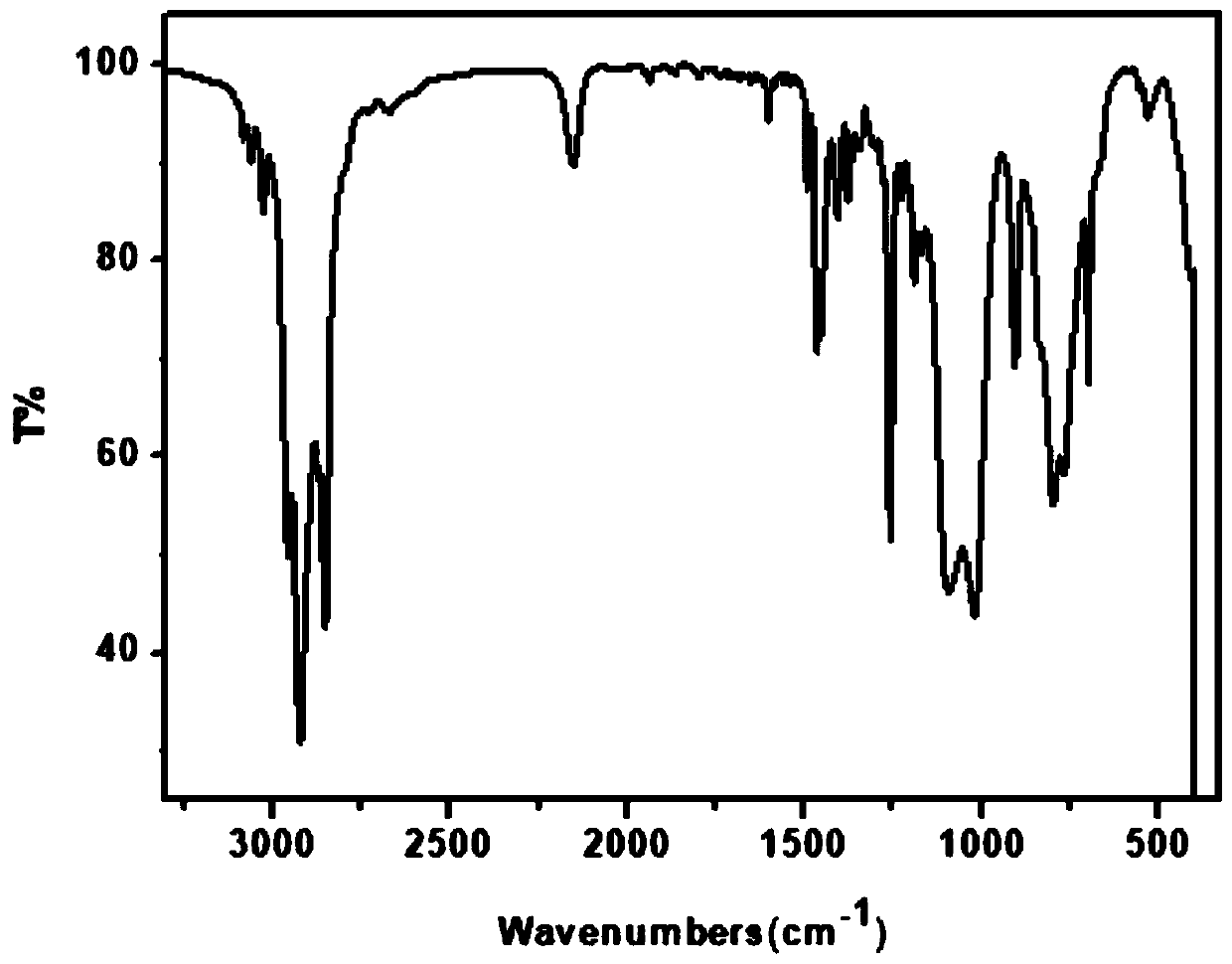

[0019] refer to figure 1 and figure 2 , a preparation method of a p-methylstyrene / 1-octene co-modified hydrogen-containing silicone oil release agent, pour 640g of hydrogen-containing silicone oil into a 2000ml three-hole flask at room temperature, stir, heat up to 80°C, drop Add 190g of p-methylstyrene and 0.5ppm Karstedt catalyst, dropwise time is 60min, then maintain at 80°C for 3h, after heating up to 100°C, add dropwise 144g octene and 0.5ppm Karstedt catalyst, dropwise time is 60min, Then maintain at 100°C for 3h, and finally cool to room temperature, vacuumize to remove low boiling, vacuum degree -0.0998MPa, maximum temperature 140°C, time 1.5h, to obtain a qualified product.

[0020] Product indicators:

[0021] Viscosity: 900~1400mpa.s;

[0022] Refractive index: 1.4500~1.4650;

[0023] Volatile content: 0.1~1%.

Embodiment 2

[0025] Pour 640g of hydrogen-containing silicone oil into a 2000ml three-hole flask at room temperature, stir, and after raising the temperature to 90°C, add 227g of p-methylstyrene and 5ppm Karstedt catalyst dropwise for 60min, and then maintain at 90°C for 6h. After the temperature was raised to 120°C, 180g of octene and 5ppm Karstedt catalyst were added dropwise for 60min, and then maintained at 120°C for 6h. Finally, cool to room temperature, vacuumize to remove low boiling, vacuum degree -0.1MPa, maximum temperature 180°C, time 1.5h, and obtain qualified product.

[0026] Product indicators:

[0027] Viscosity: 900~1400mpa.s;

[0028] Refractive index: 1.4500~1.4650;

[0029] Volatile content: 0.1~1%.

Embodiment 3

[0031] Pour 640g of hydrogen-containing silicone oil into a 2000ml three-hole flask at room temperature, stir, and after raising the temperature to 84°C, add 200g of p-methylstyrene and 2ppm Karstedt catalyst dropwise for 60min, and then maintain at 84°C for 4h. After the temperature was raised to 110°C, 150g of octene and 2ppm Karstedt catalyst were added dropwise for 60 minutes, and then maintained at 110°C for 4 hours. Finally, cool to room temperature, evacuate to remove low boiling, the vacuum degree is -0.099MPa, the highest temperature is 150°C, and the time is 1.5h, and a qualified product is obtained.

[0032] Product indicators:

[0033] Viscosity: 900~1400mpa.s;

[0034] Refractive index: 1.4500~1.4650;

[0035] Volatile content: 0.1~1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com