Acrylamide/polymerizable microsphere composite gel as well as preparation method and application thereof

A technology of acrylamide and polymerized microspheres, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of long gel formation time, difficult injection into wellbore, high viscosity of gel base fluid, etc., and can achieve tensile stress. And the effect of high compressive stress, strong adhesion and good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Embodiment 1 The preparation of AM / HEMA (acrylamide / hydroxyethyl methacrylate) copolymerized microspheres

[0067] Acrylamide / hydroxyethyl methacrylate copolymerized microspheres (AM / HEMA copolymerized microspheres) were synthesized by low temperature inverse microemulsion method. The specific method is as follows: first prepare the oil phase, weigh a certain amount of Span 80 (span 80), Tween 60 (Tween 60) and No. 10 white oil in a three-neck flask, stir in a water bath at 50 ° C for 0.5 h at a constant temperature, The rotating speed is 300r / min; then the water phase is prepared, and a certain amount of acrylamide (AM), hydroxyethyl methacrylate (HEMA), N,N-methylenebisacrylamide (MBA), over Potassium sulfate (KPS), deionized water, stirred at room temperature until completely dissolved; then, at 20°C, add the water phase to the oil phase dropwise at a rate of 2-3 drops / s, and the stirring rate is 500r / s min, after emulsification for 0.5h, cool down to 18°C, add sodi...

Embodiment 2

[0070] The processing of embodiment 2 AM / HEMA copolymerized microspheres

[0071] Weigh 2g of the AM / HEMA copolymerized microspheres prepared in Example 1 in a three-necked flask, add 40mL of acetone as a solvent, and stir for 0.5h at 40°C and 300r / min, then add 5mL of methacryloyl chloride, continue Stir for 0.5h, add 0.05g anhydrous Na 2 CO 3 ;Continue to stir and react for 12h; then wash with deionized water for 3 times, and continue to centrifuge with a centrifuge to obtain the desired microspheres, because the surface of the microspheres contains carbon-carbon double bonds, which can be polymerized with itself or acrylamide monomers , so named polymerizable AM / HEMA copolymer microspheres.

Embodiment 3

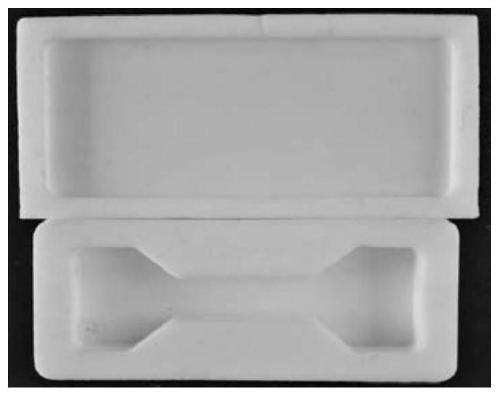

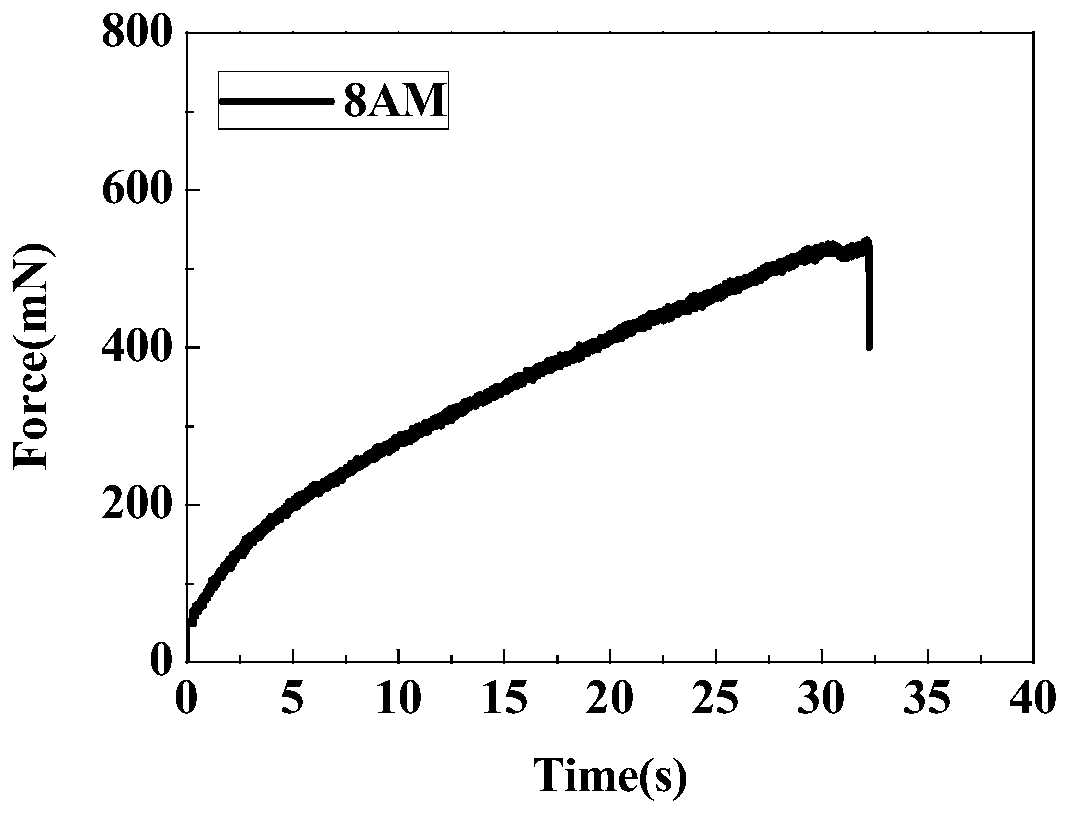

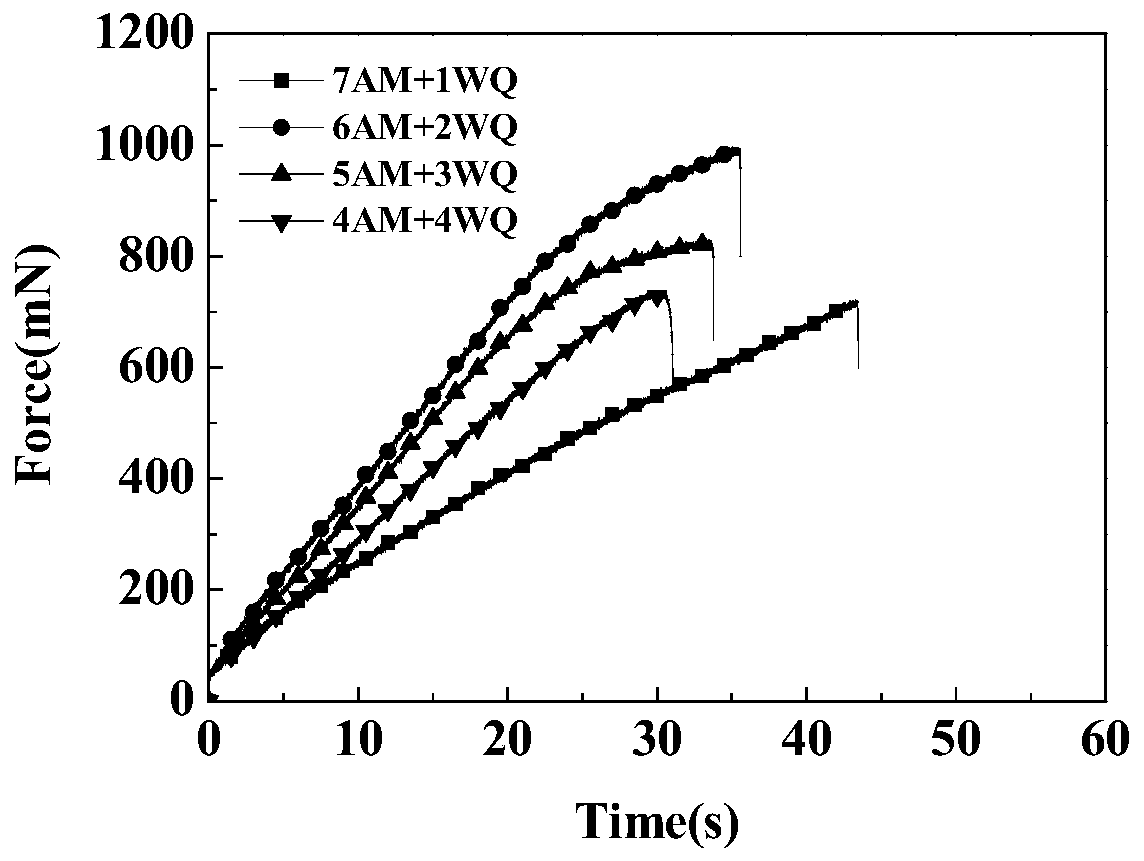

[0072] Example 3 Preparation of acrylamide / polymerizable microsphere composite gel

[0073] Slowly add microspheres while stirring in deionized water (one is the AM / HEMA copolymerized microspheres (WQ) prepared in Example 1, and the other is the polymerizable AM / HEMA copolymerized microspheres (CQ) prepared in Example 2 ), ultrasonically oscillated for 20 min and then stirred for 30 min to ensure a uniform solution. Add acrylamide to the above solution and continue to stir for 2h, then add 0.04wt% N,N-methylenebisacrylamide and 0.04wt% potassium persulfate, and continue to stir for 30min. The cross-linking system was kept at a constant temperature of 70° C. for 4 hours to obtain an acrylamide / polymerizable microsphere composite gel. The specific formulation of the acrylamide / polymerizable microsphere composite gel is shown in Table 2 and Table 3.

[0074] Table 2 Acrylamide / AM / HEMA copolymerized microsphere composite gel formula

[0075]

[0076] Table 3 Acrylamide / Polym...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive stress | aaaaa | aaaaa |

| Compressive stress | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com