Absorption type water chilling unit for preparing low-temperature cold water

A water chiller and absorption technology, which is applied in refrigerators, refrigeration components, adsorption machines, etc., can solve the problems of inability to produce low-temperature cold water, complex system structure, and high investment costs, and achieve small investment, simple system, and improved efficiency. The effect of operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

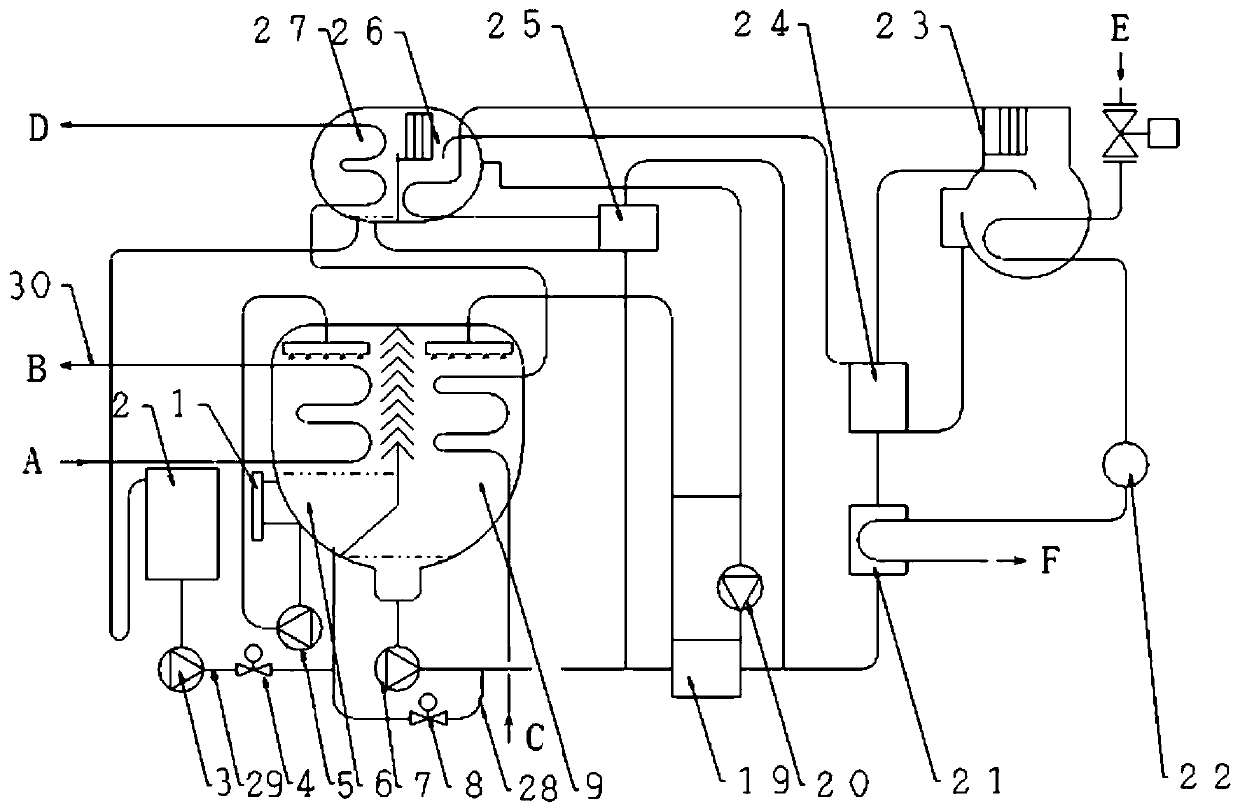

[0023] like figure 1 Shown is a flow chart of an absorption chiller for producing low-temperature cold water according to the present invention, which is mainly composed of the following components: condenser 27, absorber 9, evaporator 6, high-temperature regenerator 23, low-temperature regenerator 26 , low temperature heat exchanger 19, high temperature heat exchange 24, condensate water heat exchanger 25, heat recovery device 21, dilute solution pump 7, concentrated solution pump 20, refrigerant circulation pump 5, chilled water inlet A, chilled water outlet B, Cooling water inlet C, cooling water outlet D, driving heat source inlet E, driving heat source outlet F and corresponding connecting pipelines. The evaporator 6 and the absorber 9 are arranged in the same cylinder, the condenser 27 and the low temperature regenerator 26 are arranged in the same cylinder, and the high temperature regenerator 23 is separately arranged in a cylinder. The absorption chiller uses lithium...

Embodiment 2

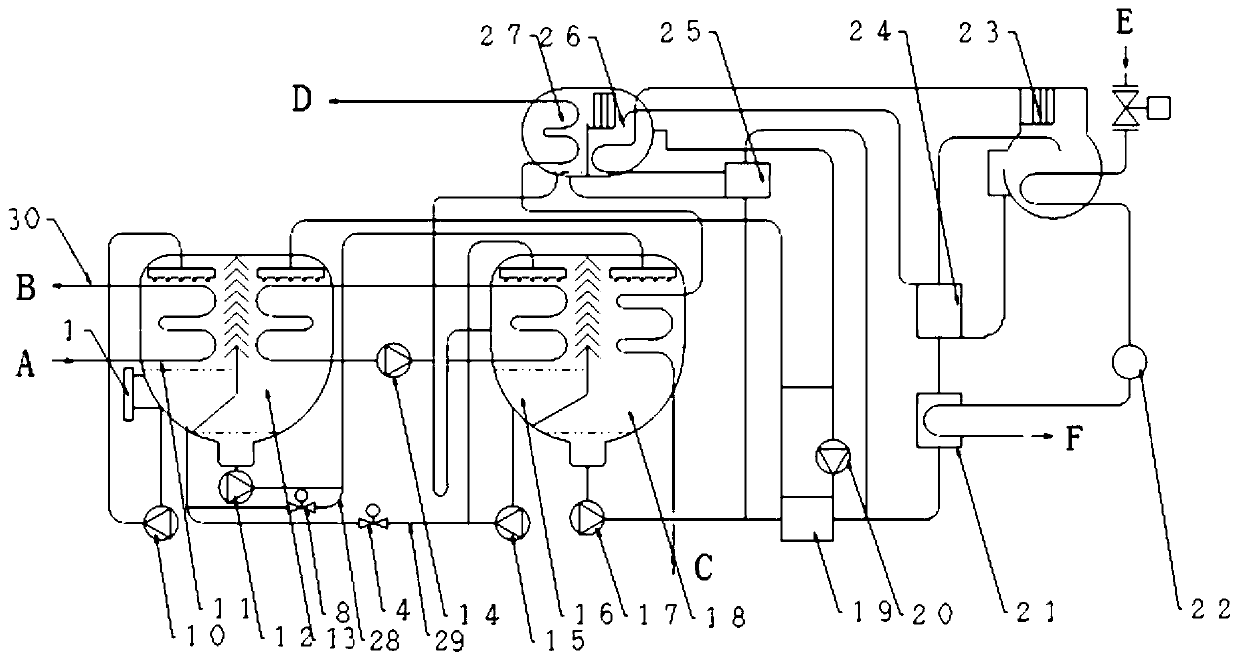

[0027] like figure 2 Shown is the flow chart of another absorption chiller for producing low-temperature cold water according to the present invention. Compared with the previous scheme, the absorber and evaporator of this unit adopt a two-stage absorption structure. The evaporator includes a low-pressure absorber 13 and a high-pressure absorber 18, the evaporator includes a low-pressure evaporator 11 and a high-pressure evaporator 16, the low-pressure evaporator 11 and the low-pressure absorber 13 are arranged in the same cylinder, and the high-pressure evaporator 16 and the high-pressure absorber 18 are arranged. In the same cylinder, the condenser 27 and the low-temperature regenerator 26 are arranged in the same cylinder, and the high-temperature regenerator 23 is separately arranged in one cylinder. The cooling water is connected to the high-pressure absorber 18 and the condenser 27 through the pipeline, and a circulating water pipeline is connected between the low-press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com