Positive electrode active material, preparation method thereof and sodium ion battery

A cathode active material, sodium-ion battery technology, applied in active material electrodes, positive electrodes, secondary batteries and other directions, can solve the problems of limited commercialization process, poor electrochemical performance, etc., to improve capacity performance and Coulomb efficiency, high The effect of charge-discharge specific capacity and high first-cycle Coulomb efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] Next, a preparation method of the positive electrode active material in the present application will be described. According to this preparation method, the above-mentioned positive electrode active material can be prepared. The preparation method comprises the following steps:

[0048] S10, the preparation step of sodium transition metal oxide, mixing L source, Na source, M source, Cu source, Fe source, Mn source and X source according to the preset ratio, and heat treatment in oxygen-containing atmosphere to obtain sodium transition metal oxide Metal oxide.

[0049] S20, a washing treatment step, using a washing solution to wash the sodium transition metal oxide, the pH of the washing solution is 3-13, preferably 6-12.

[0050] S30, a re-washing treatment step, using deionized water to perform a re-washing treatment on the sodium transition metal oxide after the washing treatment.

[0051] S40, a drying treatment step, drying the sodium transition metal oxide after...

Embodiment 1

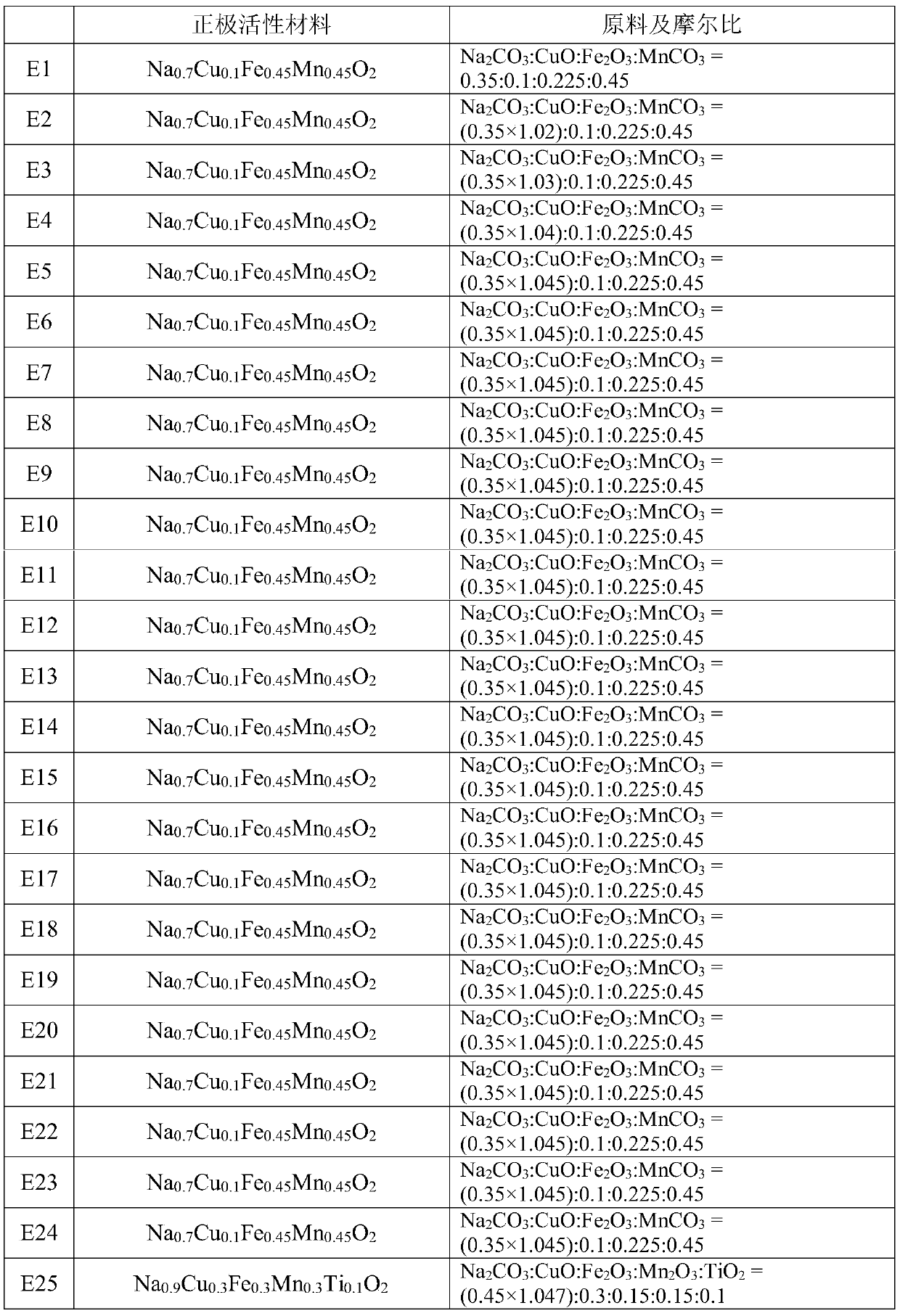

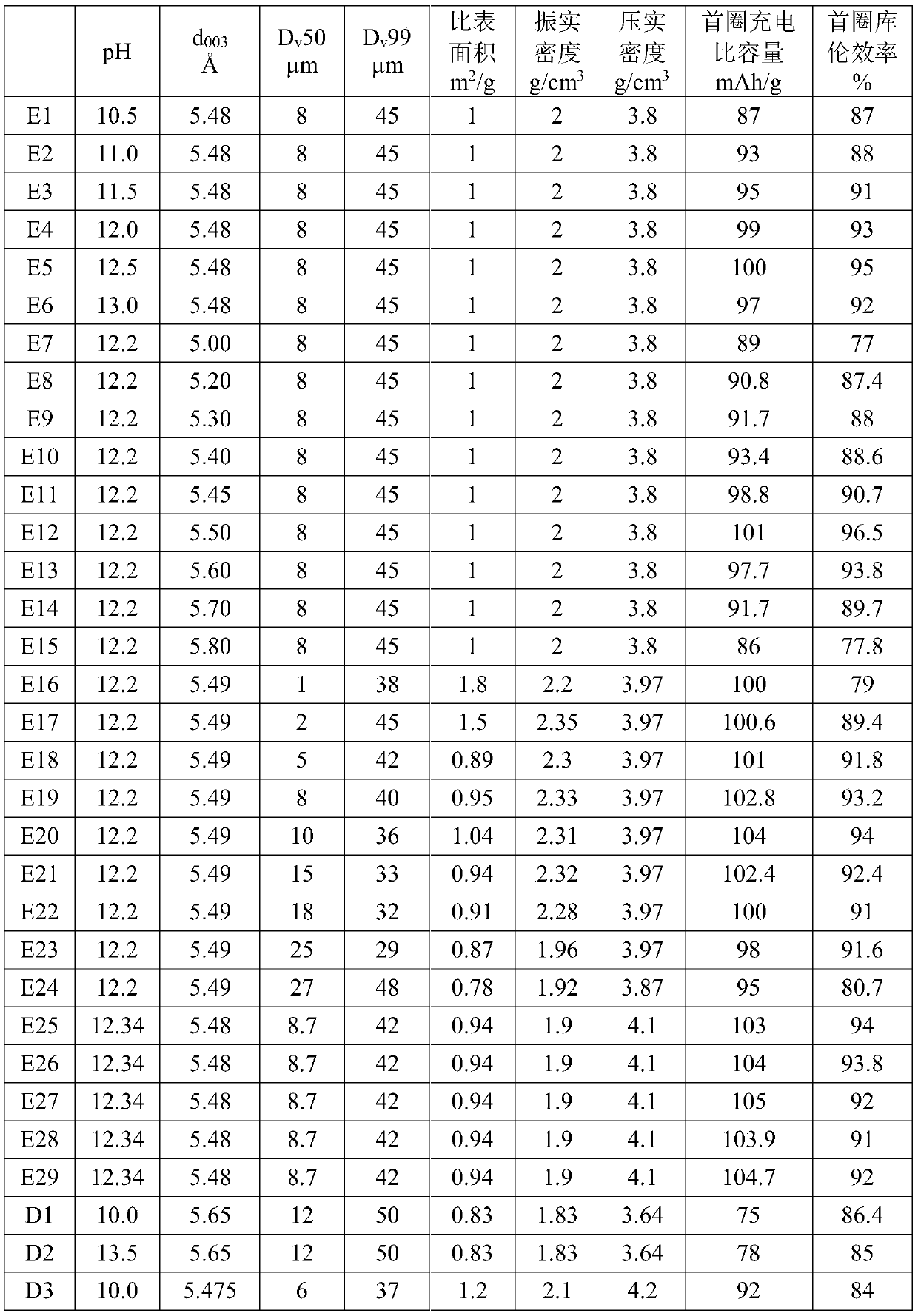

[0094] Preparation of cathode active material

[0095] Sodium carbonate (Na 2 CO 3 ), copper oxide (CuO), iron oxide (Fe 2 o 3 ) and manganese carbonate (MnCO 3 ) according to the molar ratio Na 2 CO 3 :CuO:Fe 2 o 3 :MnCO 3 =0.35:0.1:0.225:0.45 mixed evenly, that is to say that the actual mass of the Na source in the mixed raw material is 100% of the theoretical mass, after that, the relative humidity is 4% of the air atmosphere, 950 ℃ for 12 hours, after natural cooling, Sodium transition metal oxide Na 0.7 Cu 0.1 Fe 0.45 mn 0.45 o 2 . The resulting sodium transition metal oxide was ground into D v 50≈8μm, D v 99≈45μm, and then mixed with an appropriate amount of pH=6 washing solution (the detergent is acetic acid) to form a mixed material with a solid content of 30wt%, stirred at 30°C at a speed of 200rpm for 10min, repeated washing 3 times, and then transitioned with sodium Wash again with deionized water of equal quality to the metal oxide, repeat the wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap