Energy-saving thermal insulation building wall

A technology for building walls and thermal insulation, applied in buildings, building components, building structures, etc., can solve the problems of poor thermal insulation effect, poor seismic and flame retardant performance, high density, etc., and achieve the effects of convenient installation, low cost and low density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

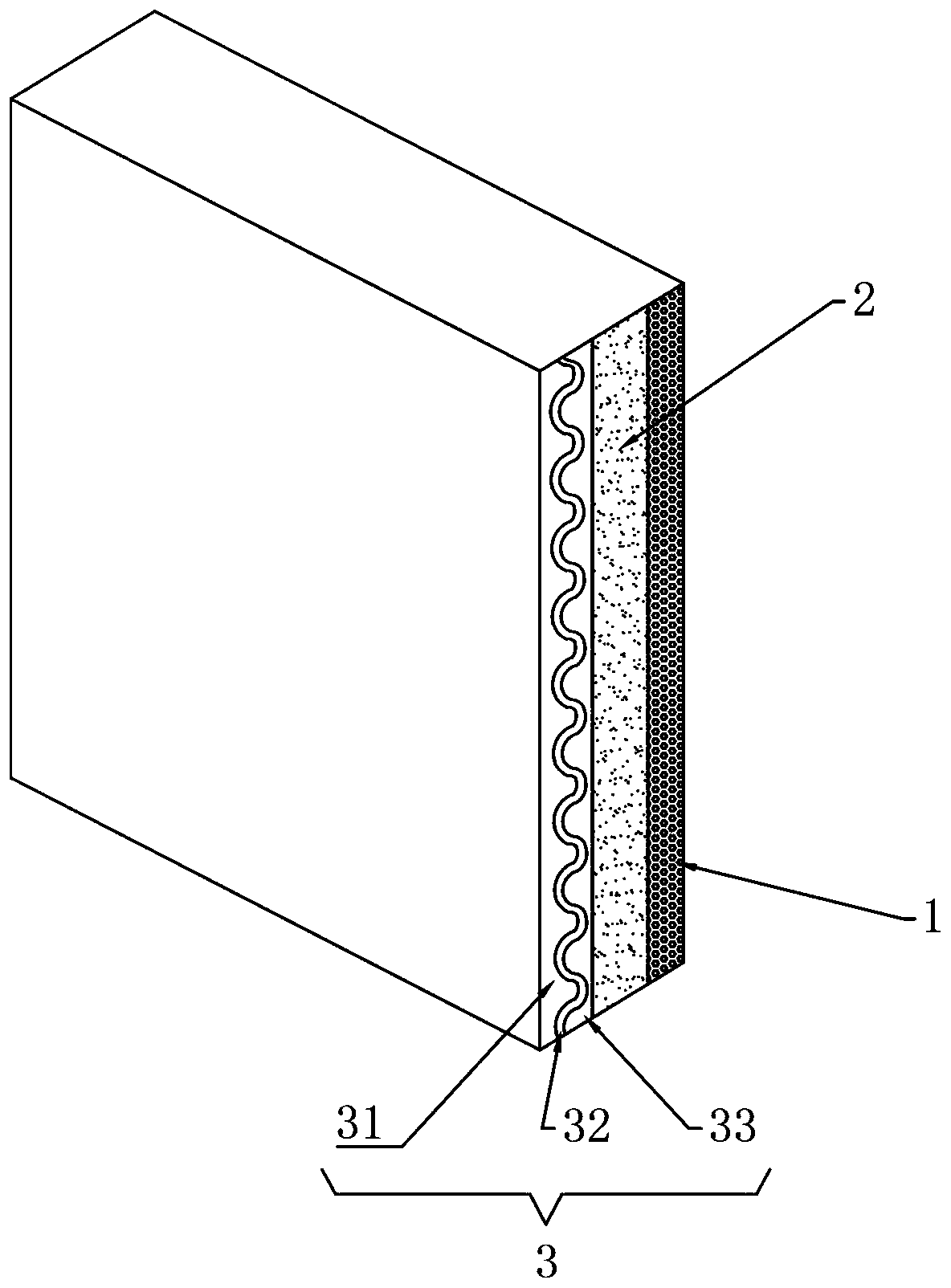

[0031] see figure 1 , this implementation provides an energy-saving and heat-insulating building wall, including a heat-preservation and fireproof layer 1, an intermediate filling layer 2, a sound insulation layer 3, and a supporting steel structure located in the middle filling layer 2, wherein:

[0032] The insulation layer 1 is made of the following raw materials in parts by weight: 100 parts of unsaturated polyester resin, 35 parts of styrene, 1.5 parts of foaming agent, 3 parts of curing agent, 3 parts of surfactant, 30 parts of flame retardant, 30 parts of thermal insulation cement, 10 parts of asbestos;

[0033] The middle filling layer 2 is made of the following raw materials in parts by weight: 25 parts of lightweight ceramics, 30 parts of lightweight concrete, 15 parts of expanded perlite, 12 parts of polyethylene, 15 parts of silicon carbide, 6 parts of alkali-resistant glass fiber, 10 parts of wood fiber, 12 parts of calcium carbonate, 3 parts of binder, 2 parts o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com