Direct-vat-set high-viscosity modifier with high viscosity and toughness, and preparation method thereof

A direct-injection, high-viscosity technology, applied in the field of asphalt modifiers, can solve the problems of reduced viscosity and toughness of asphalt mixtures, achieve good fatigue resistance and thermal stability, improve antistatic effect, and good comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

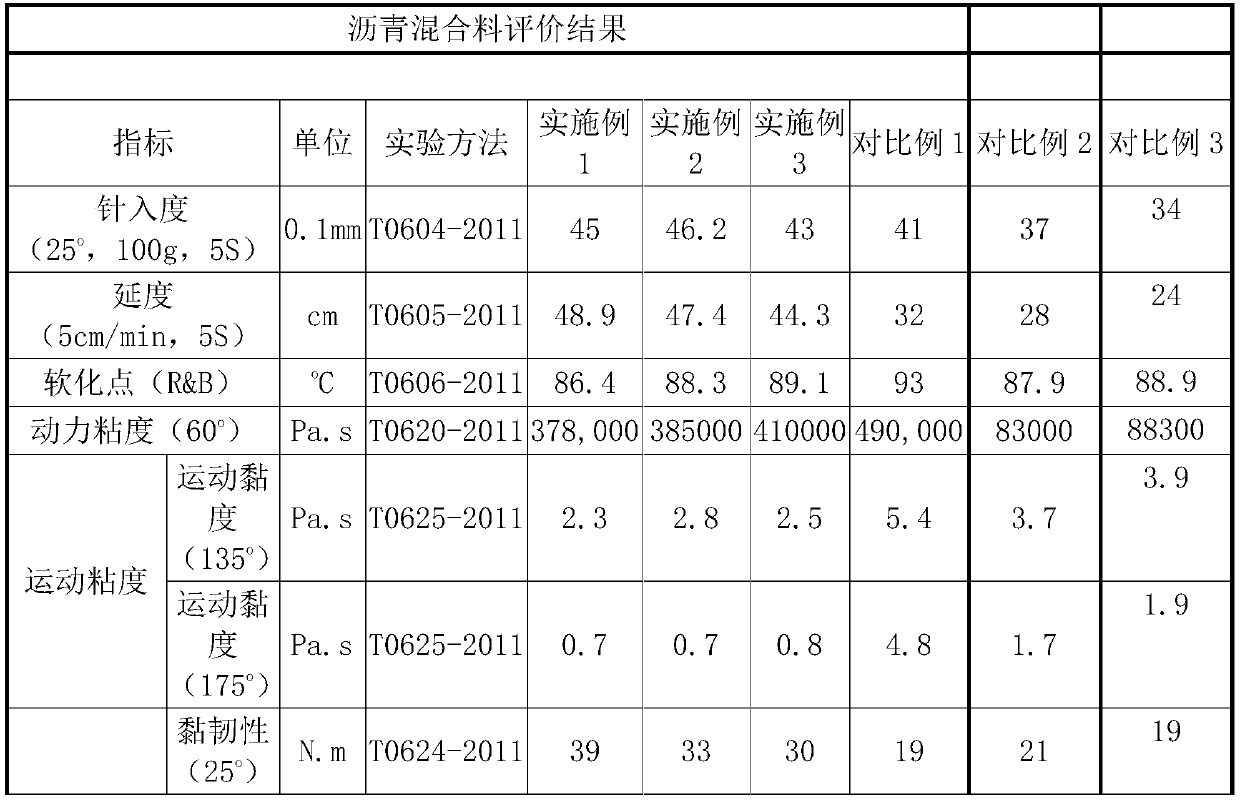

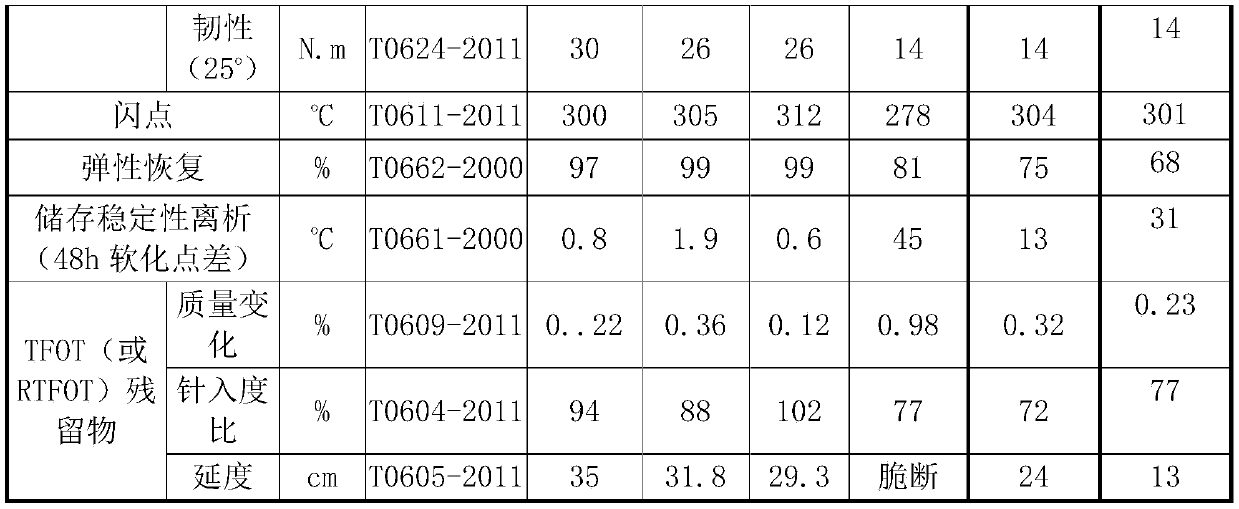

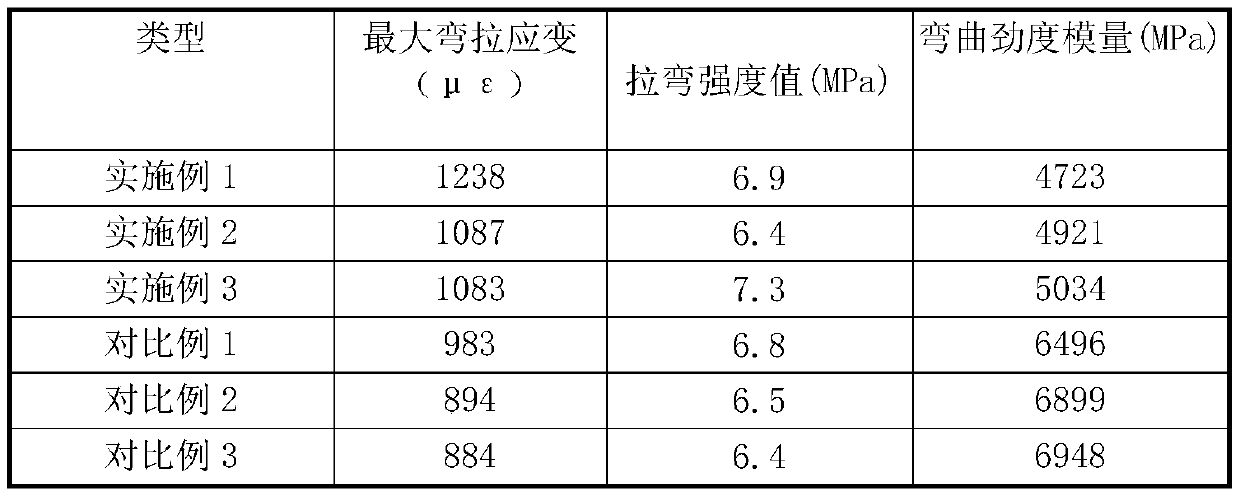

Examples

Embodiment 1

[0025] This embodiment provides a direct-throwing high-viscosity high-viscosity modifier, which is mainly prepared from the following components in parts by weight: 20 parts of Pebax elastomer, 8.5 parts of polyglycolic acid resin, 70 parts Part of K resin, 0.5 part of erucamide, 0.5 part of antioxidant 1010, 0.5 part of talcum powder.

[0026] This embodiment also provides the preparation method of modifying agent, specifically comprises the following steps:

[0027] Step 1: Mix the above-mentioned Pebax elastomer, polyglycolic acid resin, K resin, erucamide, and antioxidant 1010 in a high-speed mixer for 60 minutes at a speed of 500 rpm, and prepare it at a temperature of 60° C. Mixture.

[0028]Step 2: Melt and knead the mixture in a twin-screw extruder. The extrusion temperature is 180°C, the screw speed is 300rpm, and then extruded. After cooling and drying, talc powder is added to obtain a direct-input high-viscosity, toughness, and high-viscosity product. Modifier.

Embodiment 2

[0030] This embodiment provides a direct-throwing high-viscosity high-viscosity modifier, which is mainly prepared from the following components in parts by weight: 35 parts of Pebax elastomer, 13.5 parts of polyglycolic acid resin, 50 parts Part of K resin, 0.7 part of erucamide, 0.3 part of antioxidant 168, 0.5 part of diatomaceous earth.

[0031] This embodiment also provides the preparation method of modifying agent, specifically comprises the following steps:

[0032] Step 1: Mix the above-mentioned Pebax elastomer, polyglycolic acid resin, K resin, erucamide, and antioxidant 168 in a high-speed mixer for 60 minutes at a speed of 500 rpm at a temperature of 60° C. Mixture.

[0033] Step 2: Melt and knead the mixture in a twin-screw extruder, the extrusion temperature is 180°C, the screw speed is 300rpm, and then extrude, after cooling and drying, add anti-adhesive diatomaceous earth to obtain a direct-input type High viscosity toughness high viscosity modifier.

Embodiment 3

[0035] This embodiment provides a direct-throwing high-viscosity high-viscosity modifier, which is mainly prepared from the following components in parts by weight: 50 parts of Pebax elastomer, 18.2 parts of polyglycolic acid resin, 30 parts 1 part of K resin, 1 part of erucamide, 0.4 part of antioxidant 246, 0.4 part of talcum powder.

[0036] This embodiment also provides the preparation method of modifying agent, specifically comprises the following steps:

[0037] Step 1: Mix the above-mentioned Pebax elastomer, polyglycolic acid resin, K resin, erucamide, and antioxidant 246 in a high-speed mixer for 60 minutes at a speed of 500 rpm at a temperature of 60° C. Mixture.

[0038] Step 2: Melt and knead the mixture in a twin-screw extruder, the extrusion temperature is 180°C, the screw speed is 300rpm, and then extrude, after cooling and drying, add anti-adhesive talc powder to obtain a direct-injection high-end product. Viscosity high viscosity modifier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com