Preparation process of water-emulsion acne-removing essence cream

The invention relates to a preparation process and a technology for removing acne, which is applied to the field of preparation technology of water-emulsion acne-removing essence cream, which can solve the problems of reducing the grinding efficiency of a grinding head, reducing the efficiency of breaking the original plant material, etc., so as to improve the grinding effect and promote the melting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

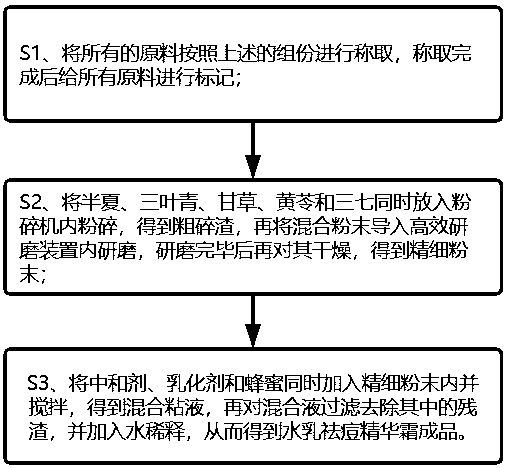

[0045] see figure 1 , a preparation process of water milk acne essence cream, comprising the following components by mass: 1-2 parts of neutralizer, 3-6 parts of pinellia, 1.3-2.7 parts of emulsifier, 5-9 parts 1-1.6 parts of clover, 1-1.6 parts of water, 2-2.8 parts of honey, 1.3-1.8 parts of Huang Ling, 2-5 parts of Panax notoginseng, 1-1.8 parts of licorice, 1-1.4 parts of acacia, Its preparation method comprises the following steps:

[0046] S1. Weigh all the raw materials according to the above components, and mark all the raw materials after the weighing is completed;

[0047] S2. Put pinellia, clover, licorice, huangling and notoginseng into the pulverizer to pulverize at the same time to obtain coarse slag, then introduce the mixed powder into the high-efficiency grinding device for grinding, and then dry it after grinding to obtain fine powder;

[0048] S3. Add neutralizer, emulsifier and honey to the fine powder at the same time and stir to obtain mixed mucus, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com