Preparation method of flexible graphene oxide/metal organic framework composite filter membrane

A metal-organic framework, composite filtration technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as no obvious improvement in filtration effect, inability to maintain stable connection between MOFs and GO, and detachment of MOFs. Achieve the effect of easy assembly into devices, improved retention performance, and excellent flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A method for preparing a flexible graphene oxide / metal-organic framework composite filter membrane; the specific preparation process includes the following steps:

[0035] 1) Weigh graphene oxide, zinc nitrate hexahydrate and 2-methylimidazole, add respectively in the same solvent, prepare uniform graphene oxide dispersion liquid, zinc nitrate solution and 2-methylimidazole solution, and zinc nitrate solution Add it into the graphene oxide dispersion liquid, then add the 2-methylimidazole solution, and mix evenly to obtain the precursor mixed liquid.

[0036] In step 1, the solvent can be deionized water, N,N-dimethylformamide (DMF) and its aqueous solution, methanol and its aqueous solution, etc.

[0037] In step 1, the mass ratio of graphene oxide, zinc nitrate hexahydrate and 2-methylimidazole is 1:(8-16):(9-18).

[0038] In step 1, the graphene oxide concentration range in the precursor mixed liquid is 0.2-0.5mg / mL, and the concentration of zinc nitrate (as ZnNO 3...

Embodiment 1

[0047] 1. Preparation of ZIF-8@GO / GO composite membrane

[0048] 1) Weigh graphene oxide, zinc nitrate hexahydrate and 2-methylimidazole (the mass ratio of the three is 1:8:9), and add them into deionized water respectively to prepare a uniform graphene oxide dispersion, zinc nitrate solution and 2-methylimidazole solution, adding zinc nitrate solution to the graphene oxide dispersion, then adding 2-methylimidazole solution, mixing evenly to obtain a precursor mixed solution, wherein the concentration of graphene oxide is 0.5mg / mL, zinc nitrate The concentration is 2.5mg / mL, and the concentration of 2-methylimidazole is 4.5mg / mL.

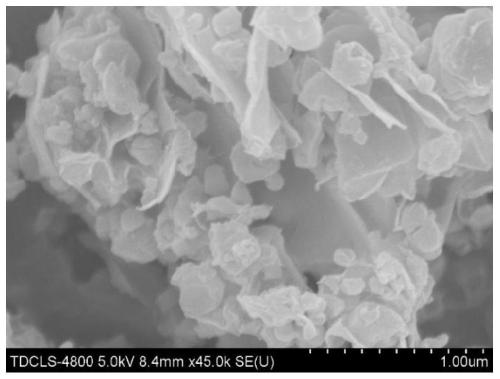

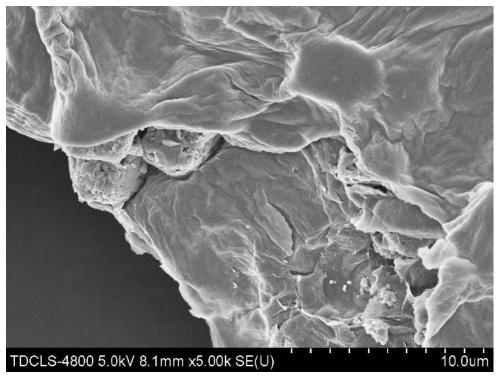

[0049] 2) Pour the precursor mixture into the reaction kettle, and heat it in an electric blast drying oven for 1 hour, set the temperature at 110°C to obtain a suspension of ZIF-8@GO composite particles, centrifuge the suspension, and wash , placed in an electric blast drying oven and dried to obtain gray-black ZIF-8@GO particles. Its SEM picture...

Embodiment 2

[0055] Preparation of ZIF-8@GO / GO Composite Membrane

[0056] 1) Weigh graphene oxide, zinc nitrate hexahydrate and 2-methylimidazole (the mass ratio of the three is 1:8:9), and add them into deionized water respectively to prepare a uniform graphene oxide dispersion, zinc nitrate solution and 2-methylimidazole solution, adding zinc nitrate solution to the graphene oxide dispersion, then adding 2-methylimidazole solution, mixing evenly to obtain a precursor mixed solution, wherein the concentration of graphene oxide is 0.2mg / mL, zinc nitrate The concentration is 1.0mg / mL, and the concentration of 2-methylimidazole is 1.8mg / mL.

[0057] 2) Pour the precursor mixture into the reaction kettle, and heat it in an electric blast drying oven for 1 hour, set the temperature at 170°C to obtain a suspension of ZIF-8@GO composite particles, centrifuge the suspension, and wash , placed in an electric blast drying oven and dried to obtain ZIF-8@GO particles.

[0058] 3) Evenly disperse g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com