Recovery and treatment method for material attached to side walls in hard alloy spray granulation, recycled material and mixed powder material

A cemented carbide, spray granulation technology, applied in the field of cemented carbide, can solve the problems of affecting the performance of cemented carbide, the loss of cobalt element, and the low utilization rate of cemented carbide material, so as to reduce the production cost, reduce the loss, metal The effect of less element loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: The treatment of the spray granulation tower and the wall attached material on the tower wall after the cemented carbide material with a cobalt content of 8% is prepared.

[0027] The phosphoric acid solution is heated, and the tower wall is washed repeatedly with a high-pressure water gun until it is completely washed, and the washing liquid is collected to obtain the tower washing material.

[0028] Use morpholine solution to adjust the pH value of the washing material to 7, and detect the Co in the washing material 2+ Then add the corresponding amount of oxalic acid solution, and stir at the same time, until the reaction is completed, let the solution stand, separate the solid and liquid, leave the precipitate, wash the precipitate with deionized water, and then dry the precipitate at 80 ° C , crushed to below 80 mesh.

[0029] Detect that the oxygen content in the precipitate is 3.72%, calculate the amount of carbon black required, mix the carbon black a...

Embodiment 2

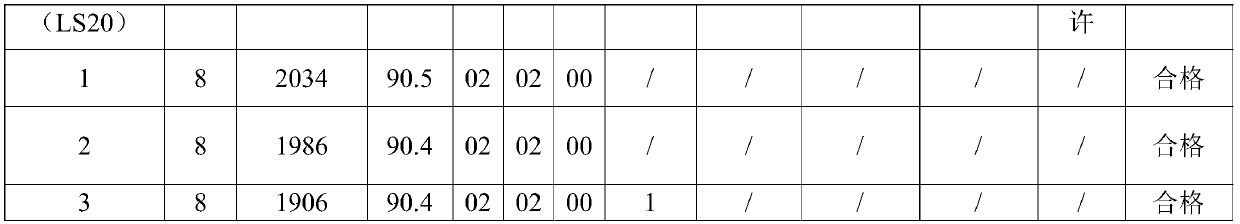

[0036] Example 2: Treatment of the spray granulation tower after the hard alloy material with a cobalt content of 6%, and the wall attached material on the tower wall.

[0037] The phosphoric acid solution is heated, and the tower wall is washed repeatedly with a high-pressure water gun until it is completely washed, and the washing liquid is collected to obtain the tower washing material.

[0038] Dilute the washing material with water, and adjust the pH value of the washing material to 7-9 with triethanolamine solution, and detect the Co in the washing material. 2+ Then add the corresponding amount of ammonium oxalate solution, and stir at the same time, until the reaction is completed, let the solution stand, separate the solid and liquid, leave the precipitate, wash the precipitate with deionized water, and then dry the precipitate at 80 ° C Dry, crush and pass through 80-mesh sieve.

[0039] Detect that the oxygen content in the precipitate is 3.65%, calculate the amount...

Embodiment 3

[0046] The difference from Example 1 is that in this example, the temperature of the vacuum calcination process is 800° C., and the rest of the steps and parameters are the same as those of Example 1.

[0047] After testing, the oxygen content in the obtained recycled material was 0.48%.

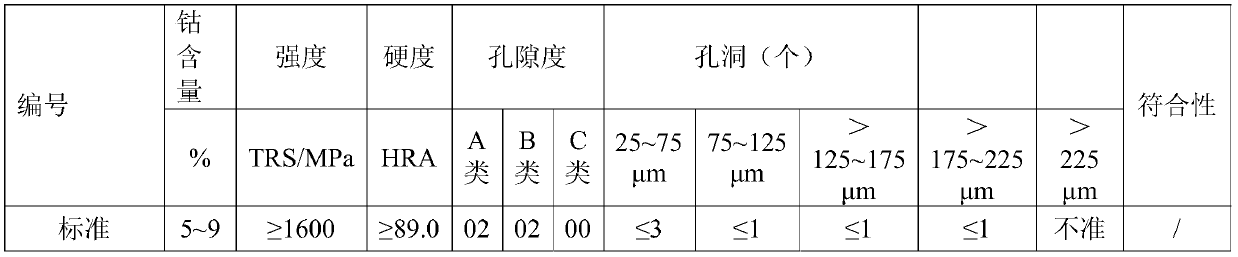

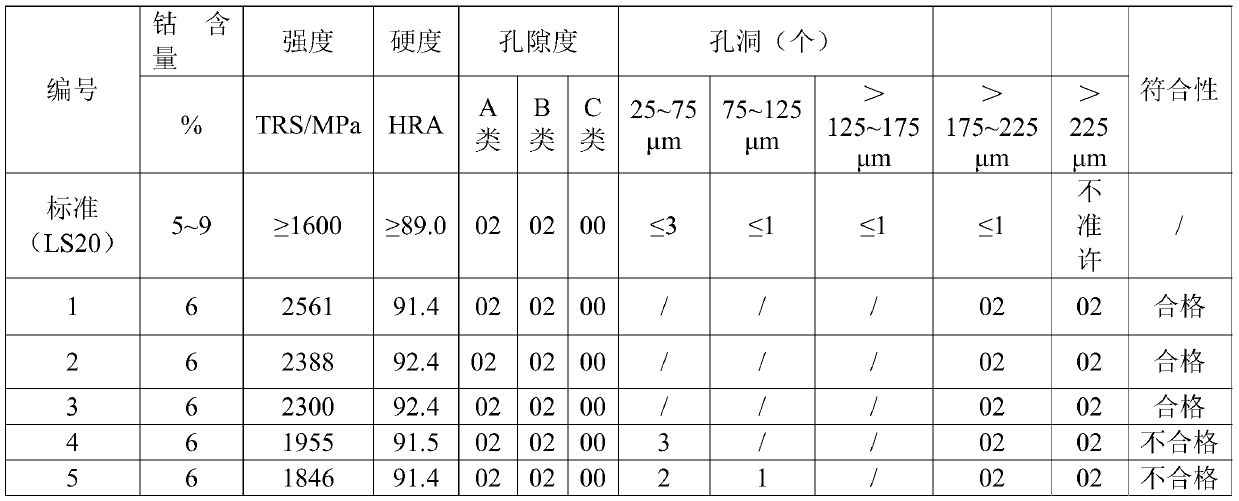

[0048] Mix the regenerated material with WC, CO powder, additives, etc. according to the mass ratio of 10%, 20%, and 30% respectively to form cemented carbide powder with a cobalt content of 8%, and ball mill it into a mixed powder under a ball mill. The mixed powder is pressed into cemented carbide sample blocks, respectively No. 1-3, and the porosity, strength and hardness of each sample block are tested respectively, and the results are shown in the following table:

[0049] Carbide performance detection result in table 3 embodiment 3

[0050]

[0051] It can be seen from Table 3 that the bending strength, Rockwell hardness, porosity and number of holes of the cemented carbide obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com