Seawater corrosion-resistant concrete member and preparation method thereof

A cement concrete and concrete technology, applied in the field of concrete components, can solve problems such as insufficient durability, poor seawater corrosion resistance, corrosion, etc., and achieve improved matrix compactness and matrix strength, strong Cl- corrosion resistance, and improved durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

[0041] Embodiment 1-9. Concrete based on ettringite cement and performance test thereof

[0042] The ettringite cement concretes of Examples 1-9 were prepared according to the mixing ratio listed in Table 1 below. The slag sulphoaluminate cement, calculated by weight percentage, is composed of 60%-90% of granulated blast furnace slag, 10-30% of anhydrite, and 5-10% of high belite sulphoaluminate cement clinker after mixing and grinding made.

[0043] The mixing ratio of table 1 embodiment 1~9 ettringite concrete

[0044]

[0045] Among them, the slag sulphoaluminate cement-based ettringite concrete was prepared with different water-binder ratios in Examples 1 to 3; in Examples 4 to 7, part of the sea sand was used to replace the river sand, and the weight ratios of the sea sand to the river sand were respectively : 1:0, 0.25:0.75, 0.5:0.5, and 0.75:0.25.

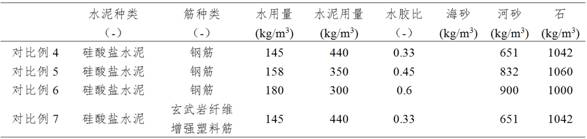

[0046] Concrete based on ordinary 42.5 Portland cement of Comparative Examples 1-3 was prepared according to the mix...

Embodiment 10~19

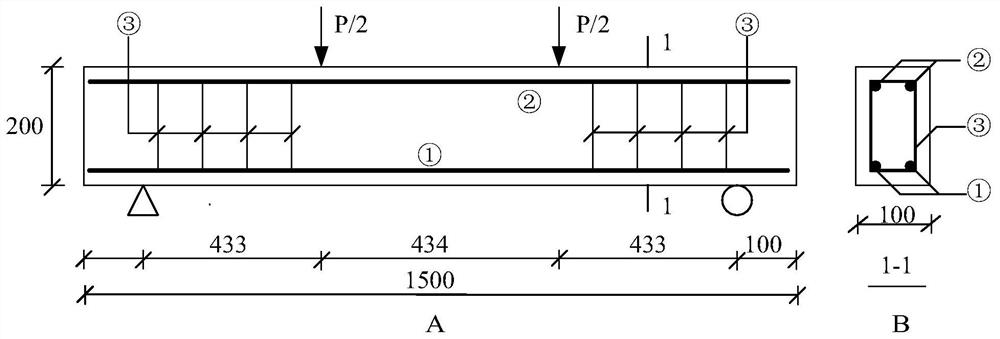

[0053] Examples 10-19. FRP bar-ettringite cement concrete member and its performance test

[0054] Obtain the FRP reinforcement-ettringite concrete member of embodiment 10~19 by pouring according to the raw material listed in following table 4 and mix ratio. The specific steps of component making are as follows:

[0055] 1) A 100mm cubic steel mold and wooden formwork are used, and round holes are symmetrically opened on both sides of the formwork for the penetration of bars of different diameters;

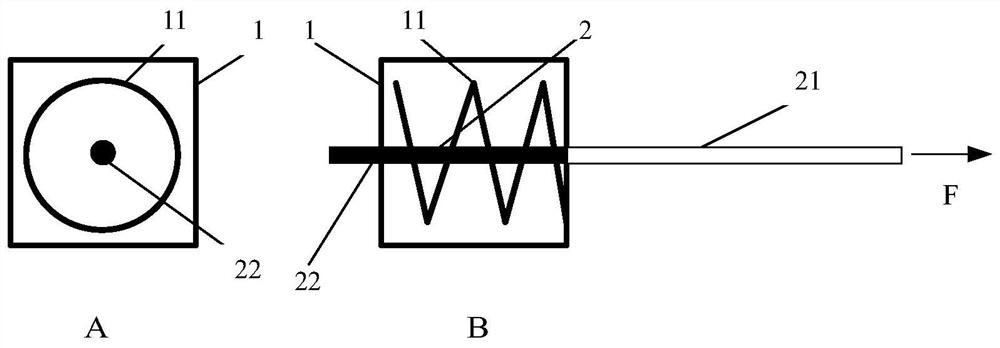

[0056] 2) In order to prevent the concrete specimen from cracking during the test, the spiral stirrup (reinforcement bar) was first added to the specimen template, and placed axially along the circular hole, and then the FRP listed in Table 4 with a length of 700mm and a diameter of 8mm The reinforcement penetrates through the symmetrical circular hole of the formwork described in 1) so that a section of its length is inside the spiral stirrup;

[0057] 3) Mix and prepare concre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com