Gel plugging agent as well as preparation method and application thereof

A technology of plugging agent and jelly, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor injection performance, increased injection pressure, high viscosity of gelling liquid, etc., to achieve improved injection performance, Effects of lower injection pressure and lower viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

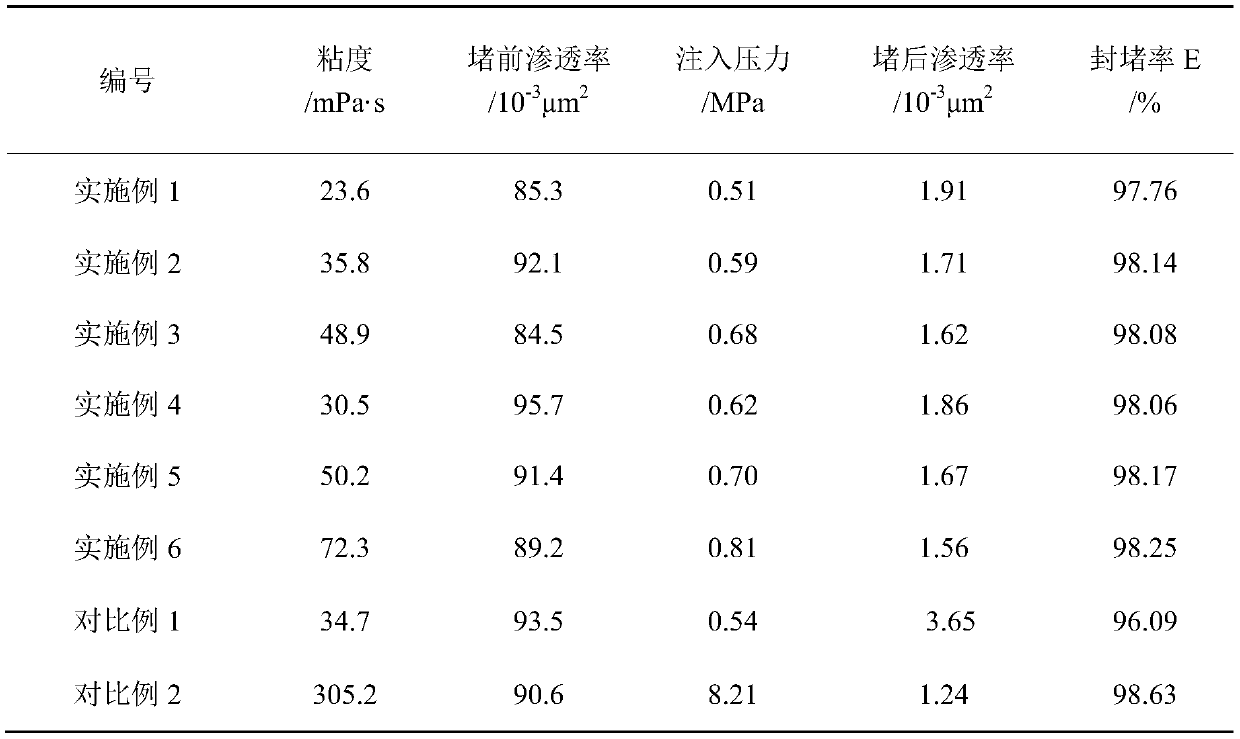

Examples

Embodiment 1

[0023] First weigh 0.5g of 200×10 4 Partially hydrolyzed polyacrylamide particles with molecular weight were added with 19.5 g of tap water to prepare 20 g of partially hydrolyzed polyacrylamide mother liquor with a mass fraction of 2.5%. Add 20g of the above-mentioned partially hydrolyzed polyacrylamide mother liquor, 0.5g of chromium acetate, 0.01g of malonic acid, 0.2g of nano-silica sol into the beaker, add 79.29g of tap water to make up the mixed solution to 100g, stir well and evenly to obtain gel liquid, the viscosity of the gelling liquid is 23.62mPa·s, and the gelling time is 48h at 40°C, and the jelly blocking agent of the present invention is obtained, and the gelling strength of the blocking agent is 15.1Pa.

Embodiment 2

[0025] First weigh 0.6g of 200×10 4 Partially hydrolyzed polyacrylamide particles with molecular weight were added with 23.4 g of tap water to prepare 24 g of partially hydrolyzed polyacrylamide mother liquor with a mass fraction of 2.5%. Add 24g of the above-mentioned partially hydrolyzed polyacrylamide mother liquor, 0.3g of chromium acetate, 0.01g of malonic acid, 0.2g of nano-silica sol, and add 75.49g of tap water to make up the mixed solution to 100g. The glue, the viscosity of the glue to be formed is 35.8mPa·s, the gelling time is 48h at 40°C, and the gelling strength of the plugging agent is 16.3Pa.

Embodiment 3

[0027] First weigh 0.7g of 200×10 4 Partially hydrolyzed polyacrylamide particles with molecular weight were added with 27.3 g of tap water to prepare 28 g of partially hydrolyzed polyacrylamide mother liquor with a mass fraction of 2.5%. Add 28g of the above-mentioned partially hydrolyzed polyacrylamide mother liquor, 0.4g of chromium acetate, 0.02g of malonic acid, 0.2g of nano-silica sol into a beaker, add 71.38g of tap water to make up the mixed solution to 100g, and stir well to obtain the finished product. Glue, the viscosity of the glue to be formed is 48.9mPa·s, the gelling time is 36h at 40°C, and the gelling strength of the plugging agent is 18.5Pa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com